Steel Mill Wire Rope Lubrication for Metallurgical Hoists: Root-Cause Fix & Proven Results

Wire rope failures in steel plants usually stem from heat, abrasive dust, and inconsistent manual lubrication. This guide presents a four-step optimization—PLC-controlled progressive lubrication, high-temperature calcium sulfonate grease, monitoring sensors, and a practical SOP—tailored for metallurgical hoists (including ladle handling). A documented field case achieved zero lubrication-related stoppages, ~50% rope life extension, and ~41% annual cost reduction.

Why Wire Rope Lubrication Fails in Steel Plants

• Grease breakdown at elevated temperatures: viscosity loss and drip-off weaken boundary protection in hot bays.

• Dust contamination and caking: embedded dust accelerates abrasive wear between wires/strands.

• Inconsistent manual lubrication: human-dependent intervals and dosing lead to under/over-lubrication.

• Monitoring blind spots: empty reservoirs or clogged lines go unnoticed, causing dry running and rapid degradation.

Result: premature wear, strand corrosion, stiffness, unplanned stoppages—raising safety risks and lifecycle cost.

4 Step Optimization That Works in High-Dust / High-Temperature Environments

1.PLC Controlled Progressive Lubrication System

• Use a progressive divider system governed by the hoist PLC.

• Baseline frequency: every 4 hours for Φ20 mm ropes; dose 0.1–0.3 ml per cycle per point.

• Tune by duty cycle, temperature, and dust level. Log cycles/alarms for traceability.

2.High Temperature Calcium Sulfonate Grease

• Operating window approx. −30°C to 220°C.

• Excellent mechanical stability, EP/anti-wear, water resistance, and corrosion protection.

• Resists dust caking better than generic lithium greases; ideal for foundry/ladle bays.

• Related solution: Foundry & Ladle Handling Overhead Cranes — https://www.slkjcrane.com/news/overhead-steel-crane-systems/

3.Monitoring Sensors & Early Warning

• Fit sensors for reservoir level and line pressure.

• Typical thresholds: oil level <10%; pressure fluctuation ±0.2 MPa triggers warning.

• Push alarms to HMI/SCADA; store events in PLC for trend analysis.

4.A Practical Lubrication SOP

• Daily visual checks; weekly cleaning of rope/guide; monthly flow calibration.

• Seasonal tuning for high/low temperature.

• Keep SOPs short, visual, auditable; integrate with work orders.

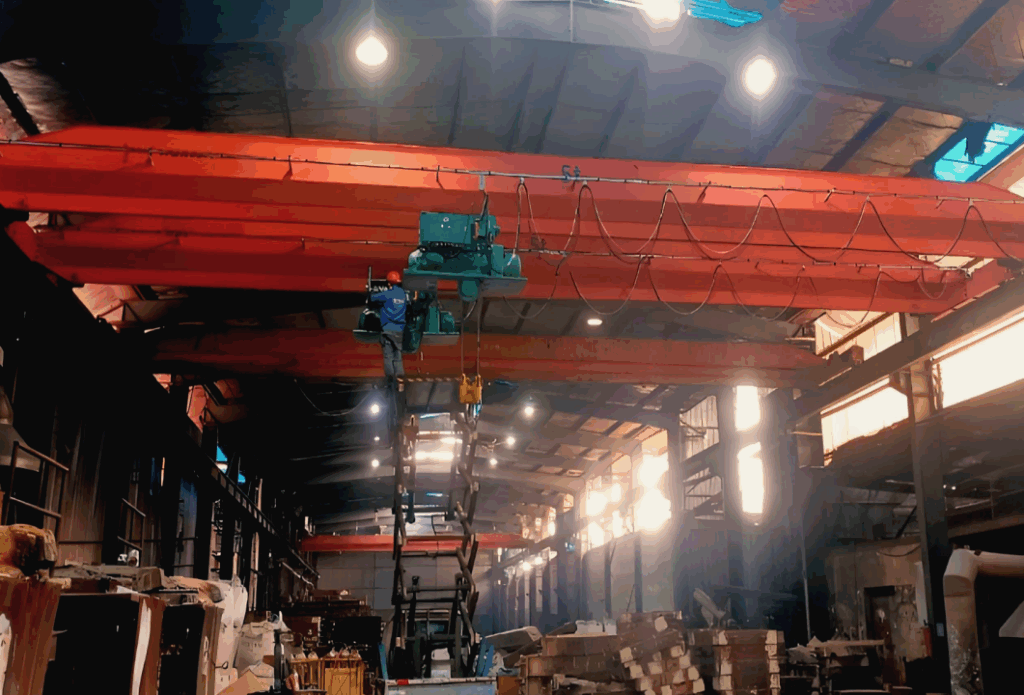

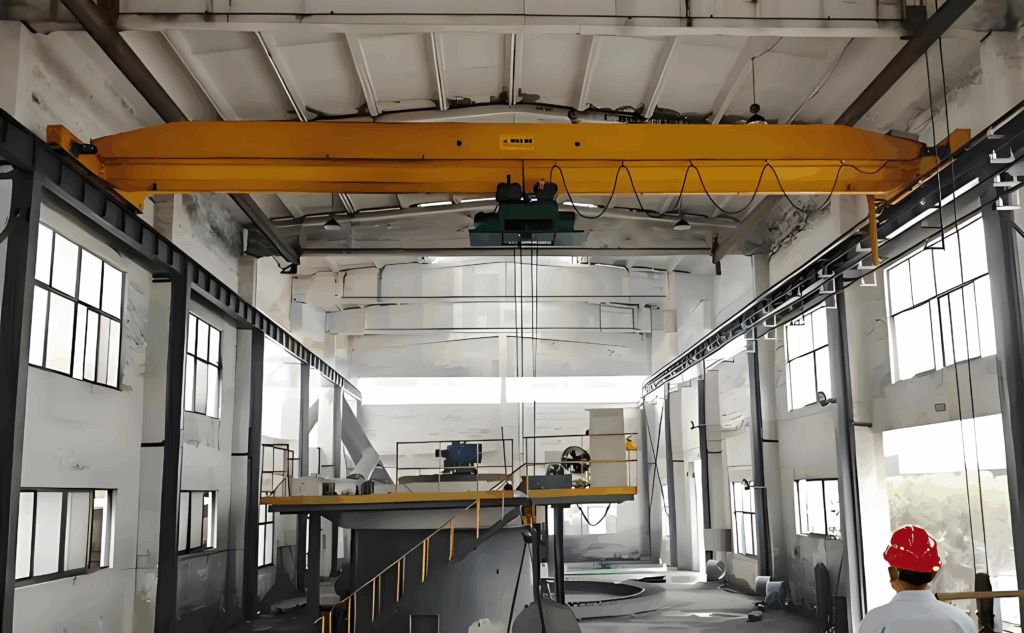

Case Study: 5 t Overhead Cranes in an Indian Steel Plant

Context: Two 5 t overhead cranes under continuous shifts, heavy dust, intermittent heat exposure. Four-step plan deployed and run for one quarter.

| Metric | Before | After | Delta | Period |

|---|---|---|---|---|

| Lubrication-related stoppages | 3 events/quarter | 0 events | −100% | 3 months |

| Wire rope service life | Baseline | ~1.5× | +50% | 3 months (annualized) |

| Annualized lubrication+downtime cost | 100% (baseline) | ~59% | −41% | 3 months (extrapolated) |

Notes: KPIs are duty-cycle and ambient-adjusted; results vary by bay temperature, dust loading, rope diameter, and reeving.

Recommended Lubrication SOP(Auditable Table)

| Task | Frequency | What to Check | Pass/Fail Criterion | Action if Fail |

|---|---|---|---|---|

| Visual check around ropes & guides | Daily | Grease film, dust caking, drip-off | Uniform film, no heavy clumps | Wipe, re-dose, adjust frequency |

| Reservoir level & alarm test | Daily | Level >25%; alarm works | Alarm at ≤10% level | Refill; fix float/sensor |

| Cleaning of rope path | Weekly | Dust accumulation at contact points | No visible cake at sheaves | Clean; inspect sheave grooves |

| Flow calibration & divider check | Monthly | 0.1–0.3 ml/cycle at each point | ±10% of setpoint | Unclog/replace divider; re-tune |

| Seasonal frequency tuning | Pre-summer/winter | Ambient temp vs. grease behavior | Stable film across shifts | Increase/decrease cycle rate |

Related Solutions for Steel Plants

• Foundry & Ladle Handling Overhead Cranes — https://www.slkjcrane.com/news/overhead-steel-crane-systems/

• Grab Bucket Overhead Cranes — https://www.slkjcrane.com/overhead-crane/grab-bucket-overhead-crane/

• Magnetic Overhead Cranes — https://www.slkjcrane.com/overhead-crane/magnetic-overhead-crane/

• Low-Headroom Overhead Cranes — https://www.slkjcrane.com/ldp-electric-single-girder-crane-low-headroom-solution/

• Maintenance & Inspection Guide — https://www.slkjcrane.com/steel-mill-overhead-crane-systems-guide/

Get a Free Lubrication Audit(CTA)

Send us your operating profile and we’ll return a tailored lubrication plan.

Please provide:

• Crane type & duty cycle (ladle handling / foundry / yard)

• Ambient temperature range

• Dust level (qualitative) & rope diameter

• Current stoppages & rope replacement interval

• Acceptable downtime & target KPIs

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen Hu

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

About the Author(Elieen)

SLKJCrane Metallurgical Application Team — 12+ years in steel-plant lifting systems, 180+ foundry/ladle projects, and standardized lubrication retrofits for high-dust, high-temperature bays.

FAQ

A practical starting point is every 4 hours for Φ20 mm ropes with 0.1–0.3 ml per cycle per point. Tune by temperature, duty cycle, and dust level. Heavier loads or hotter bays often require higher frequency.

Calcium sulfonate complex grease offers high-temperature stability, strong EP/anti-wear properties, dust resistance, and corrosion protection—well-suited for ladle/foundry operations.

Typical gains include zero lubrication-related stoppages, about 50% longer rope life, and roughly 41% annual cost reduction when the four-step plan is fully implemented.

Manual touch-ups may be needed after inspections or abnormal events, but routine lubrication should be handled by the PLC system for consistency and traceability.

In winter, verify viscosity and increase frequency if films thin. In hot/dusty seasons, watch for caking and drip-off. Re-validate flow meters and alarm thresholds after each seasonal switch.

Steel Mill Wire Rope Lubrication for Metallurgical Hoists | Cut Downtime by 41%

Steel Mill Wire Rope Lubrication for Metallurgical Hoists: Root-Cause Fix & Proven Results Wire rope failures in steel

Rubber Tyred Gantry Crane (RTG): Industrial & Container | SLKJCrane

Rubber Tyred Gantry Crane (RTG): Models, Power Options & Applications Intro (short, intent-rich):Rubber tyred gantry cranes (RTG cranes)

Explosion-Proof Overhead Cranes — LB, LXB, LHB, QB, QBE & Clean EX

Explosion-Proof Overhead Cranes Lineup for Hazardous Areas (LB / LXB / LHB / QB / QBE / Clean

Harsh Environment Overhead & Gantry Cranes

Harsh Environment Overhead & Gantry Cranes: Dust-Proof, High/Low Temperature & Anti-Corrosion Packages Why harsh environments demand specialized cranes

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice