Industrial Lightweight Lifting Solution: How to Choose and Use a Small Portable Gantry Crane

What Is a Small Portable Gantry Crane?

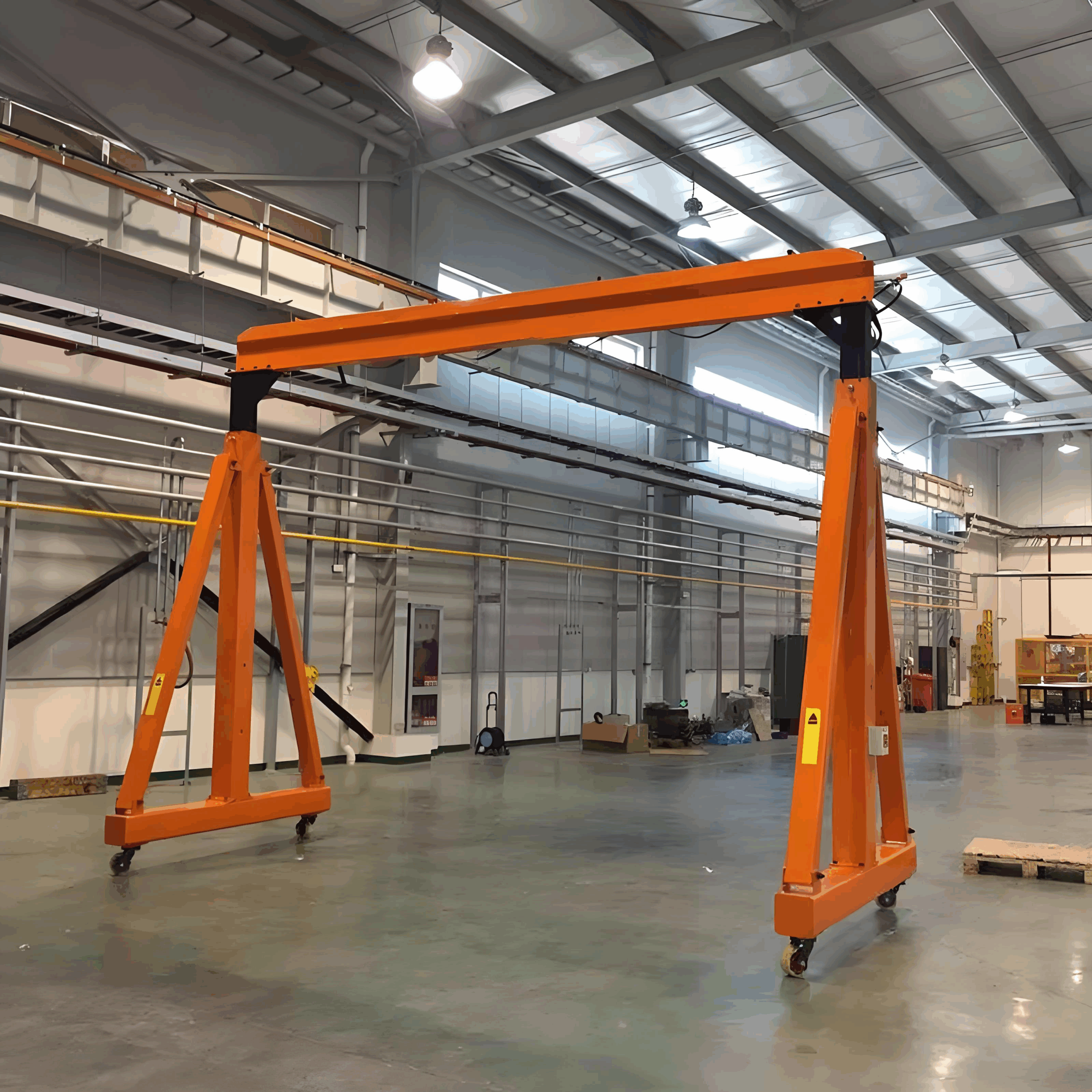

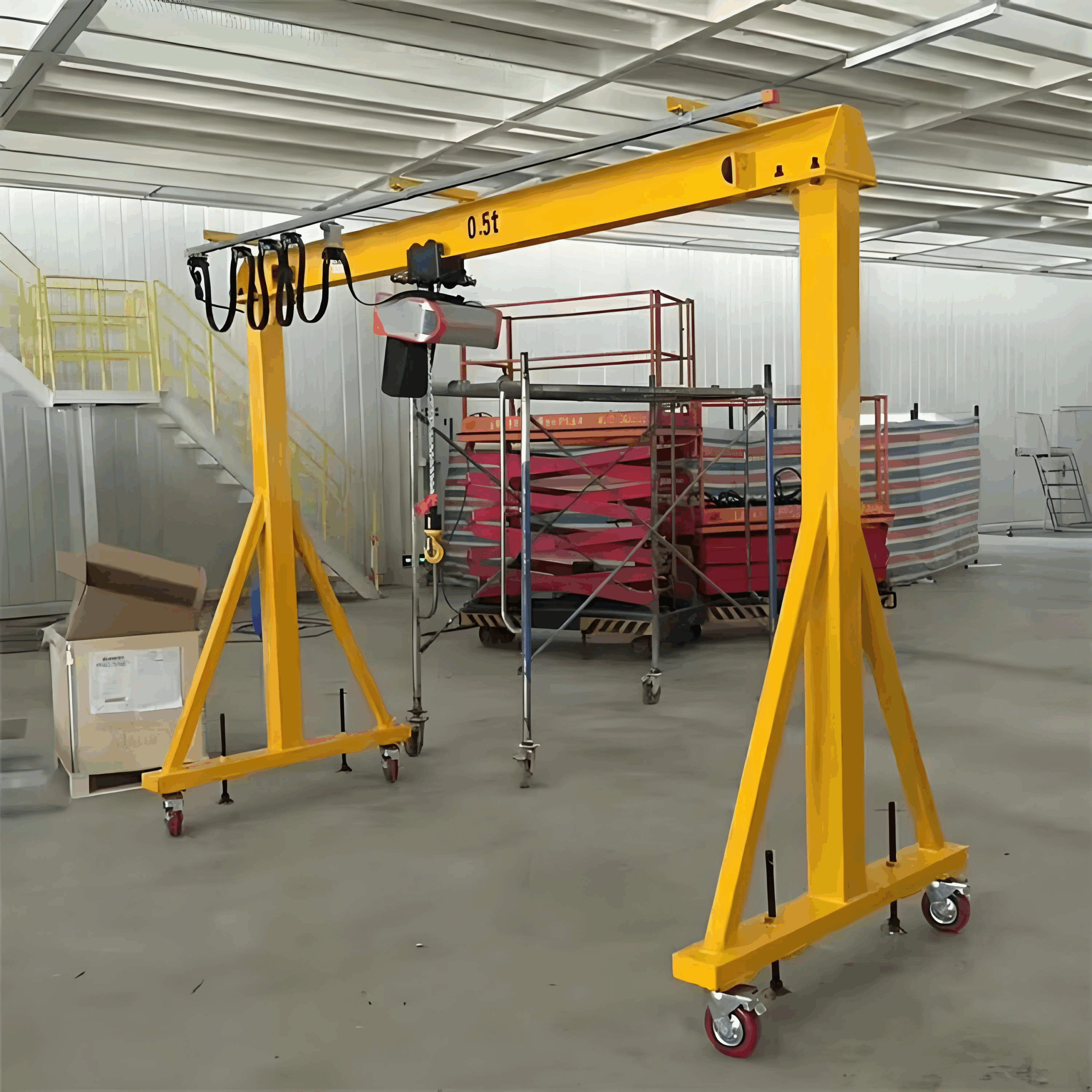

A small portable gantry crane is a type of lightweight indoor crane designed for flexible material handling. It consists of two upright columns and one horizontal beam, usually paired with an electric hoist or manual hoist as the lifting mechanism.

Key features include:

Load capacity: typically 0.5–5 tons (customizable up to 15 tons)

Span: 2–15 meters, adjustable according to site conditions

Simple structure and easy operation – no complex control systems required

Quick installation – low foundation requirements, easy to assemble and disassemble

Cost-effective – only 1/5 to 1/10 of the cost of a heavy-duty gantry crane

📌 Learn more about our full range of portable gantry cranes from SLKJCrane.

Where Can Portable Gantry Cranes Be Used?

Thanks to their mobility and compact design, mobile gantry cranes are widely applied in:

Small factories for equipment maintenance

Warehouses for loading and unloading goods

Construction sites for lightweight material handling

Automotive repair workshops

For a deeper overview of applications, visit our guide: Optimize Your Workplace: Understanding Portable Gantry Cranes.

Key Factors to Consider When Choosing a Small Gantry Crane

1. Load Capacity

| Capacity | Typical Application | Notes |

|---|---|---|

| 0.5–2 tons | Mold handling, warehouse small parts | Can use manual or electric hoist, ideal for frequent light-duty lifting |

| 3–5 tons | Medium machinery relocation, steel or pipe lifting | Stronger beam and legs required, electric hoist recommended |

| 5+ tons | Heavy equipment installation, large workpieces | Closer to heavy-duty gantry crane class, check ground load-bearing capacity |

2. Space and Dimension Matching

Span: the distance between the legs. It must cover your lifting area (e.g., truck body width or workstation length) plus 0.5–1m clearance on each side.

Height: includes leg height (floor to bottom of beam) and lifting height (hoist hook’s max reach). Ensure full clearance for the workpiece.

3. Mobility Options

Fixed type: bolted to the floor, highly stable, ideal for permanent workstations.

Mobile type: equipped with caster wheels (often for ≤2t). Easily pushed by hand within a workshop for short-distance transfers.

4. Safety & Accessories

Safety systems: overload protection, limit switches to prevent hook collision, and reliable brakes (essential for mobile designs).

Hoist selection: manual chain hoist for light, low-frequency jobs; electric hoist for heavy-duty and frequent lifting. Always confirm power supply compatibility.

Best Practices for Safe Use

Before Use

Check columns, beam connections, chains, and brake systems.

Ensure the ground is level, obstacles are cleared, and no personnel stand within the working radius.

During Operation

Lift smoothly at a constant speed to avoid swing.

Control movement speed when repositioning the crane.

Never overload the crane—always follow the rated capacity.

Maintenance

Regularly lubricate moving parts such as bearings and chains.

Clean dust and debris after operation.

When idle for long periods, dismantle and store in a dry, ventilated place.

Why Choose SLKJCrane?

SLKJCrane specializes in portable gantry cranes, mobile gantry cranes, and indoor lifting solutions. Our equipment features high-quality materials, stable structures, and tailored customization for specific industries. We also provide professional selection guidance and after-sales service, ensuring safety and efficiency for every lifting operation.

👉 Whether you need a manual gantry crane for light tasks or an indoor crane system for heavy-duty applications, SLKJCrane is your reliable partner.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen Hu

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

Frequently Asked Questions (FAQ) About Small Portable Gantry Crane

No. Altering the span or capacity changes the load-bearing structure and can cause accidents. Always consult the manufacturer for customization.

Yes, but select anti-rust materials or apply protective coatings. Ensure solid ground and avoid strong wind conditions.

Many adjustable portable cranes are designed with wheels for mobility. Portability depends on weight, material, and frame design.

Intermodal Gantry Cranes (RMG & RTG) — Engineering Playbook

Intermodal Gantry Cranes (RMG & RTG) — Engineering Playbook This engineering-oriented guide targets rail-to-truck operations, inland ports (ICDs),

Electric Hoist Gantry Crane: Complete Sizing & Selection Guide | SLKJCrane

Electric Hoist Gantry Crane: A Complete Sizing & Selection Guide Choosing the right electric hoist gantry crane comes

MG Double Girder Gantry Crane with Hook | Heavy-Duty Outdoor Lifting

MG Double Girder Gantry Crane with Hook: Structure, Specs & Applications An MG double girder gantry crane with

Steel Mill Wire Rope Lubrication for Metallurgical Hoists | Cut Downtime by 41%

Steel Mill Wire Rope Lubrication for Metallurgical Hoists: Root-Cause Fix & Proven Results Wire rope failures in steel

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice