Shipbuilding Gantry Crane vs General Gantry Crane: 7 Key Design Differences

In many projects we hear a similar question:

“Can I use a general gantry crane instead of a shipbuilding gantry crane to save cost?”

The short answer is: for serious shipbuilding work, you usually cannot.

On paper, both are “gantry cranes”. In practice, their working conditions, design standards and failure risks are very different. This article explains 7 key design differences between a shipbuilding gantry crane and a general-purpose gantry crane, so you can make the right decision for your shipyard.

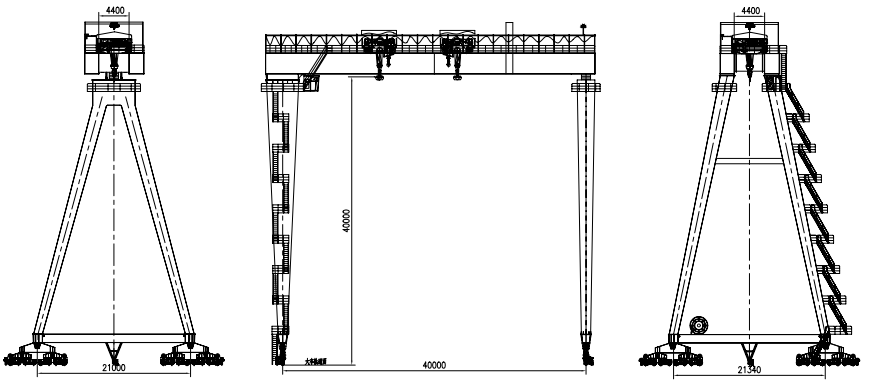

1. Span and Coverage: One Slipway vs Many Building Lines

A general gantry crane is often designed for:

-

Warehouses

-

Fabrication yards

-

Steel stockyards

Span and coverage are usually limited to one working area.

A shipbuilding gantry crane, by contrast:

-

Commonly spans an entire slipway or dry dock

-

Often needs to cover multiple block assembly lines

-

Must leave room for side walkways, service lanes and clearance for hull blocks

That is why you see spans of 60–100+ m on shipbuilding gantry cranes, not typical 20–40 m spans used in general factories.

If you want to see typical span ranges by ship type, refer to our guide:

“Shipbuilding Gantry Cranes for Different Ship Types – Capacity, Span and Configuration Guide”

👉 /shipbuilding-gantry-crane-ship-type-capacity

2. Capacity and Safety Margins for Heavy Hull Blocks

General gantry cranes may handle:

-

Pallets

-

Steel plates and beams

-

Machinery and components

Shipbuilding gantry cranes, however, must lift:

-

Large hull blocks

-

Pre-outfitted deck modules

-

Engine-room and accommodation modules

This is why shipbuilding gantry cranes often work in the range of:

-

80–400 t and above

-

With 10–25% safety margins over the heaviest block or module

For conventional ship types, 10% may be enough.

For LNG carriers, oil tankers and high-risk ship types, 25% or more is common.

3. Dual Trolleys and Multi Point Lifting for Long Blocks

Most general gantry cranes have:

-

A single trolley

-

One hoist (or at most, one main + one auxiliary)

This is fine for compact loads.

In shipbuilding, many hull blocks and deck modules are:

-

Long and asymmetric

-

Sensitive to bending and twisting during lifting

A shipbuilding gantry crane therefore typically includes:

-

Dual trolleys with synchronized control

-

Multiple lifting points and special lifting beams

-

Control systems designed to limit differential speed between trolleys

Without these features, long hull blocks could deform, crack or misalign during erection.

4. Anti-Wind and Storm Protection for Coastal Yards

General gantry cranes often work:

-

Indoors, or

-

In relatively sheltered outdoor environments

Shipbuilding gantry cranes are usually installed at:

-

Seafront slipways

-

Open dry docks

-

Coastal block assembly yards

Design must therefore consider:

-

High design wind speeds (Beaufort 10–12, or even 14 in typhoon areas)

-

Rail clamps and storm anchors sized for these wind loads

-

Parking positions and emergency procedures during storms

This level of anti-wind engineering is rarely required for general-purpose gantry cranes.

For more on wind design and environment classes (C4 vs C5-M), you can also check our ship-type guide page.

5. Anti Corrosion Levels: C4 vs C5-M Marine Environments

General gantry cranes may use standard industrial coatings suitable for:

-

Inland factories

-

Mild industrial atmospheres

Shipbuilding gantry cranes work in much harsher conditions:

-

Salt spray from the sea

-

High humidity

-

Continuous exposure to sun and rain

That is why shipbuilding gantry cranes often use:

-

C5-M marine-grade coating systems for seafront yards

-

Multi-layer paints with total thickness ≥ 200 μm

-

Optional hot-dip galvanizing on selected parts

This brings both higher initial protection and long-term durability under marine corrosion.

6. Explosion Proof and Low Temperature Options (Tankers & LNG)

In a general yard, you may never need explosion-proof or low-temperature features.

In tanker and LNG shipbuilding, you often do:

-

Explosion-proof electricals (Ex d IIB T4 Gb or equivalent)

-

Low-temperature steel and components able to operate at −40 °C or lower

-

Stainless-steel lifting devices to avoid rust contamination in sensitive modules

These are not “add-ons” you can retrofit easily. They must be considered from the first day of design.

7. Integration into a Shipyard Lifting Strategy

Finally, a general gantry crane usually serves one area with limited interaction with other cranes.

A shipbuilding gantry crane is part of a whole lifting strategy:

-

It must cooperate with yard RTGs, overhead cranes, yard trailers and SPMTs

-

It affects block division, building sequence and cycle time

-

Its parameters (capacity, span, lifting height) directly define what ship types your yard can build in the future

In other words, a shipbuilding gantry crane is not just a piece of equipment – it is a strategic asset.

If you want a deeper look at lifting strategy, see our article:

“What Is a Shipyard Lifting Strategy? The Role of Shipbuilding Gantry Cranes in Block Construction”

When Should You Choose a Shipbuilding Gantry Crane?

Choose a true shipbuilding gantry crane if:

-

You are lifting hull blocks or large deck modules

-

Your crane will sit over a slipway or dry dock

-

You plan to build new or larger ship types in the next 10–15 years

-

You need dual trolleys, multi-point lifting, C5-M coatings, anti-wind and explosion-proof options

For general fabrication or warehouse tasks, a general-purpose gantry crane is often sufficient.

For serious shipbuilding, the right choice is clear.

If you already know your target ship types and block weights,

use our shipbuilding gantry crane by ship type – capacity & span guide as a starting point,

then contact SLKJCrane for a tailor-made proposal.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

Latest Blog

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua

Free Standing Gantry Crane Solutions | SLKJCrane

Free Standing Gantry Crane Solutions for Existing and Leased Buildings Why Many Workshops Struggle to Install an Overhead

Shipbuilding Gantry Crane vs General Gantry Crane

Shipbuilding Gantry Crane vs General Gantry Crane: 7 Key Design Differences In many projects we hear a similar

Shipbuilding Gantry Cranes by Ship Type | Capacity & Span Guide

Shipbuilding Gantry Cranes for Different Ship Types – Capacity, Span and Configuration Guide | SLKJCrane In modern modular

Intelligent Warehouse Overhead Crane 1–20 Ton | Heavy-Duty AS/RS Solutions

Intelligent Warehouse Overhead Crane for Heavy-Duty AS/RS | SLKJCrane In heavy-duty warehouses such as steel coil storage, mold

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice