How to Extend the Lifespan of Your Overhead Crane: Expert Strategies for 2025

With the global overhead crane market projected to reach $6.66 billion by 2029 3, maximizing equipment longevity is critical for reducing operational costs and maintaining productivity. This guide explores proven methods to extend your crane’s service life while aligning with 2025’s technological advancements in automation and sustainability.

1. Implement a Proactive Overhead Crane Maintenance Schedule

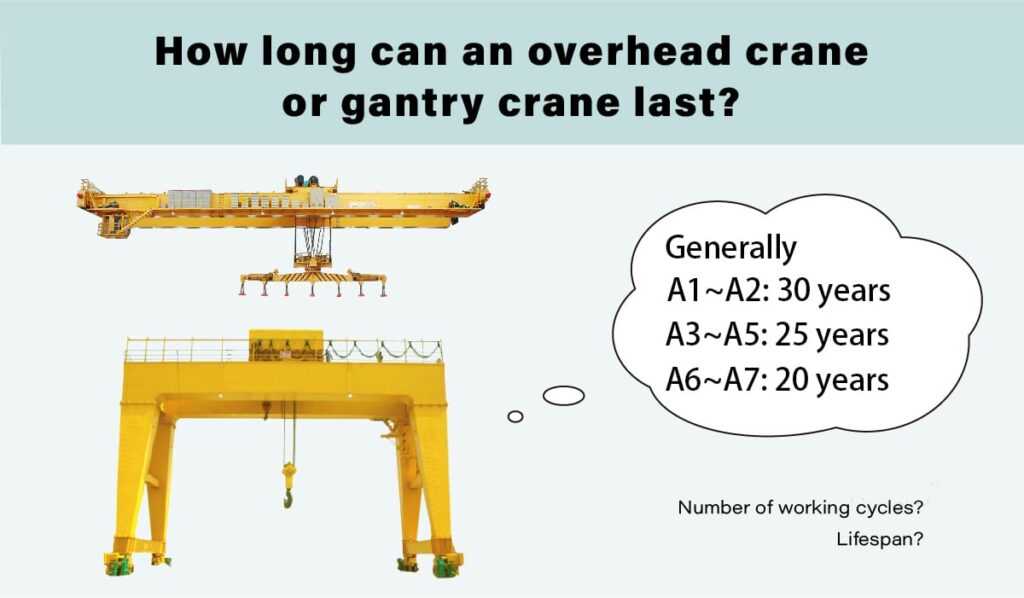

Regular maintenance is the cornerstone of crane longevity. According to CMAA standards, cranes can last 20–50 years with proper care, but neglecting inspections can slash this lifespan by 40%

1.1 Daily, Weekly, and Monthly Checks

-

Daily: Inspect hooks, wire ropes, and brakes for wear; test emergency stop functions.

-

Weekly: Lubricate gears, check electrical connections, and verify load-limiting devices.

-

Monthly: Perform structural inspections for cracks or corrosion, particularly in coastal environments.

Example: A steel plant using this schedule reduced unplanned downtime by 27% and repair costs by $125,500/year

1.2 Annual Load Testing and Certification

SHENLI mandates annual load testing to validate rated capacity. Partner with certified technicians to:

-

Test braking systems under 110% of maximum load.

-

Document results for compliance audits (e.g., ISO 4301, CMAA Spec 78)

2. Upgrade to Smart Overhead Crane Technologies

Integrating IoT and AI-driven systems can boost lifespan by 30% while cutting energy costs by 20%

2.1 Predictive Maintenance Systems

-

Sensor Networks: Monitor motor temperature, vibration, and wire rope tension to detect failures 72 hours in advance.

-

Data Analytics: Platforms like Konecranes’ X-Series reduce downtime by 35% through AI-driven diagnostics

2.2 Energy-Efficient Retrofits

-

Regenerative Braking: Recaptures 15–20% of energy during lowering operations.

-

Variable Frequency Drives (VFDs): Optimize motor speed, reducing wear on mechanical components

3. Optimize Overhead Crane Operational Practices

Improper usage accounts for 43% of crane failures in manufacturing plants. Mitigate risks through:

3.1 Operator Training Programs

-

VR Simulations: Train staff on collision avoidance and load balancing in hazardous environments.

-

Certification: Ensure compliance with OSHA 1910.179 and ASME B30.2 standards

3.2 Load Management Best Practices

-

Avoid side-loading or exceeding rated capacity, which increases structural stress by 200%.

-

Use anti-sway AI systems to stabilize loads in windy conditions

4. Replace Aging Overhead Crane Components Strategically

4.1 High-Risk Parts to Prioritize

| Component | Failure Rate | Replacement Interval |

|---|---|---|

| Wire Ropes | 32% | 3–5 years |

| Hoist Motors | 25% | 7–10 years |

| Brake Pads | 18% | 2–3 years |

4.2 Cost-Effective Upgrades

-

Radio Remote Controls: Eliminate pendant cable wear and improve operator safety.

-

Modular Electrical Panels: Simplify repairs and future IoT integrations

5. Environmental Adaptations for Overhead Crane Durability

-

Radio Remote Controls: Eliminate pendant cable wear and improve operator safety.

-

Modular Electrical Panels: Simplify repairs and future IoT integrations

5.1 Corrosion Protection

-

Apply zinc-aluminum coatings to structural components in coastal or chemical plants.

-

Use IP66-rated motors in high-humidity environments

5.2 Temperature Management

-

Install hydraulic cooling systems for cranes operating above 50°C (e.g., steel mills).

-

Winterize lubricants in sub-zero conditions to prevent viscosity breakdown

6. Leverage OEM Partnerships for Overhead Crane Longevity

Collaborating with manufacturers like SHENLI provides:

-

Custom Maintenance Plans: Tailored to your crane’s duty cycle (e.g., CMAA Class D for high-intensity use).

-

Warranty Compliance: Adhering to OEM guidelines preserves warranty coverage and ensures peak performance.

Case Study: A port operator using Conductix-Wampfler’s IoT kits extended crane lifespan by 8 years while achieving ROI in 14 months

7. Document and Analyze Overhead Crane Performance

7.1 Digital Record-Keeping

Use CMMS software to track:

-

Inspection histories

-

Repair costs

-

Component failure patterns

7.2 Lifespan Forecasting

Apply predictive analytics to estimate remaining service life based on:

-

Total working cycles (e.g., 2.5×10⁵ cycles for medium-duty cranes) 11

-

Environmental stress factors

Conclusion: Transform Your Overhead Crane into a Long-Term Asset

By combining routine maintenance, smart upgrades, and operator training, businesses can extend crane lifespans by 40–60% while reducing total ownership costs. For a free crane health assessment or customized IoT integration plan, contact our experts today.

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: info@slkjcrane.com

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice