Selecting the Ideal Mini Spider Crane: Factors to Consider

When it comes to lifting heavy loads in confined or challenging spaces, mini spider cranes (also known as compact crawler cranes) are indispensable. Their compact design, agility, and versatility make them ideal for construction sites, urban projects, indoor installations, and even events. However, choosing the right spider crane requires careful consideration of several factors to ensure efficiency, safety, and cost-effectiveness. In this guide, we’ll break down the key elements to evaluate before making your decision.

1. Load Capacity and Reach

The primary purpose of a spider crane is to lift and maneuver loads safely. Start by assessing your project’s maximum load requirements. Spider cranes typically offer capacities ranging from 1 ton to 20 tons, with varying boom lengths. Consider:

- Maximum weight: Ensure the crane can handle your heaviest loads, including rigging equipment.

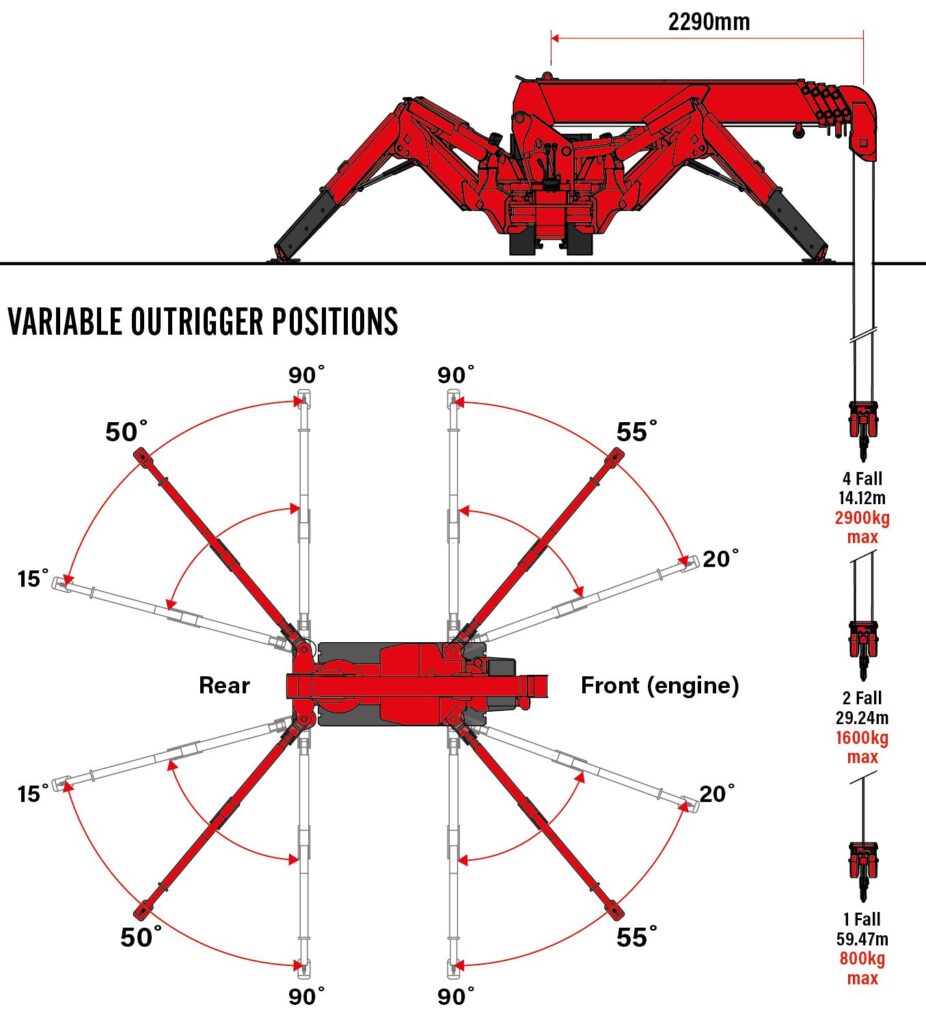

- Boom length and radius: Determine the required reach (horizontal and vertical) to access hard-to-reach areas.

- Lifting charts: Review the manufacturer’s load charts to confirm performance under different configurations.

2. Workspace Constraints

Spider cranes excel in tight spaces, but every project has unique limitations. Evaluate:

- Site access: Will the crane need to pass through narrow doorways, elevators, or uneven terrain? Opt for models with retractable tracks or compact dimensions.

- Indoor vs. outdoor use: Ensure the crane has appropriate features (e.g., non-marking tires for indoor floors, weather-resistant components for outdoor sites).

- Ground conditions: Check if the crane requires stabilizers or outriggers for stability on soft, uneven, or elevated surfaces.

3. Mobility and Transport

Spider cranes are designed for easy transport, but their mobility features vary. Key considerations include:

- Weight and size: Lightweight models are easier to move but may sacrifice lifting capacity.

- Crawler tracks vs. wheels: Crawlers provide better traction on rough terrain, while wheeled options are faster on flat surfaces.

- Disassembly: Can the crane be broken down into smaller components for transport in standard vehicles?

4. Power Source

Depending on the environment, choose a crane with the right power system:

- Electric models: Ideal for indoor projects or noise-sensitive areas (e.g., hospitals, theaters).

- Diesel/hydraulic models: Better suited for outdoor use, offering higher power and durability for heavy-duty tasks.

- Hybrid options: Combine electric and diesel power for flexibility in mixed environments.

5. Safety Features

Safety is non-negotiable. Look for:

- Anti-tip systems: Automatic sensors or alarms that prevent overloading.

- Remote control operation: Allows precise maneuvering from a safe distance.

- Fail-safe brakes: Ensure load stability even in case of power loss.

- Certifications: Verify compliance with industry standards (e.g., CE, OSHA).

6. Ease of Assembly and Operation

Time is money on any job site. Prioritize cranes that:

- Require minimal setup: Modular designs or pre-assembled components reduce downtime.

- Offer intuitive controls: User-friendly interfaces and remote operation improve efficiency.

- Include training/support: Ensure operators are trained to use the crane safely and effectively.

7. Cost and ROI

While budget is a key factor, focus on long-term value:

- Purchase vs. rental: For short-term projects, renting may be more economical.

- Maintenance costs: Check warranty terms, availability of spare parts, and service networks.

- Resale value: Reputable brands often retain higher resale prices.

8. Brand Reputation and Support

Choose a manufacturer or supplier with a proven track record. Look for:

- Technical support: Availability of 24/7 assistance or on-site troubleshooting.

- Customer reviews: Feedback from other users can highlight strengths and weaknesses.

- Customization options: Some brands offer tailored solutions for unique project needs.

Final Tips for Decision-Making

- Test before buying: Request a demonstration or trial period to assess performance.

- Compare multiple models: Create a checklist to weigh pros and cons systematically.

- Consult experts: Engage with engineers or industry specialists to validate your choice.

Conclusion

Selecting the ideal spider crane involves balancing technical specifications, site requirements, and budget constraints. By prioritizing factors like load capacity, mobility, safety, and support, you can invest in equipment that maximizes productivity and minimizes risks. Always partner with trusted suppliers and prioritize training to ensure your team can harness the crane’s full potential.

Whether you’re working on a high-rise facade, a concert stage, or a renovation project, the right spider crane will be your ultimate ally in conquering tight spaces and complex lifts.

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: info@slkjcrane.com

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice