How to Adjust the Lifting Speed of a 5 Ton Spider Crane

Selecting the ideal boom crane (or hydraulic mobile crane) requires balancing technical specifications, operational demands, and budget constraints. Whether for construction, logistics, or industrial applications, this guide breaks down critical factors to ensure you make an informed decision.

1. Analyze Project Requirements

- Load Capacity & Reach

- Core Rule: Load capacity decreases as boom length increases due to the inverse relationship between lifting radius and weight. For example, a 50-ton crane with a 30-meter boom may only lift 10 tons at full extension.

- Formula:Effective Capacity=Rated Capacity×Lifting CoefficientBoom Length×Radius×Efficiency Factor (0.7–0.85)Effective Capacity=Boom Length×RadiusRated Capacity×Lifting Coefficient×Efficiency Factor (0.7–0.85)

- Always cross-check with the crane’s load chart for accuracy.

- Lifting Height & Radius

- For tasks like steel beam installation in high-rise buildings, prioritize cranes with telescopic booms (e.g., Liebherr LTM 1450 with 80-meter reach).

- For confined spaces, compact models like Tadano GR-800XL offer flexibility with a 40-meter boom and 8-ton capacity.

2. Evaluate Site Conditions

- Terrain & Stability

- Crawler Boom Cranes: Ideal for soft or uneven ground due to low ground pressure and stability.

- Truck-Mounted Cranes: Best for urban projects requiring mobility on paved surfaces.

- Space Constraints

- Overhead obstructions (e.g., power lines) require cranes with vertical clearance optimization.

- “Low-profile” boom cranes minimize spatial footprint in warehouses or factories.

3. Prioritize Versatility & Features

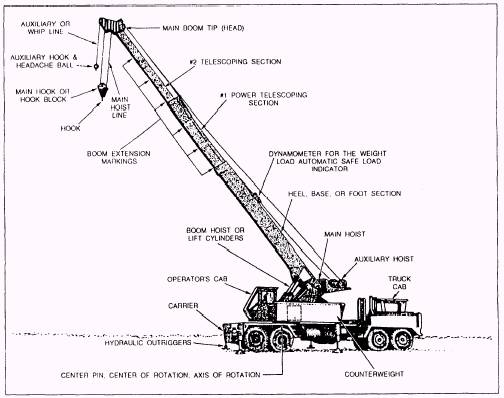

- Boom Configurations

- Telescopic Booms: Adjustable length for dynamic reach.

- Lattice Booms: Lightweight design for heavy loads at fixed radii (common in tower cranes).

- Specialized Attachments

- Jibs, winches, or grapples enhance functionality for tasks like material handling or demolition.

- Hybrid/Electric Models

- Sustainable options reduce emissions and fuel costs in eco-sensitive zones.

4. Cost & Long-Term Value

- Purchase vs. Rent

- Short-term projects (e.g., 3–6 months) benefit from renting to avoid maintenance overheads.

- Long-term use justifies investing in durable models.

- Operational Efficiency

- Compare fuel consumption: Hydraulic cranes consume 10–15% less fuel than older mechanical models5.

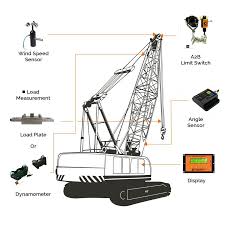

- Automated systems (e.g., load moment indicators) reduce human error and downtime.

5. Safety & Maintenance

- Compliance Standards

- Ensure adherence to ISO 4309 (crane inspections) and ANSI B30.5 (mobile crane safety).

- Critical Maintenance Checks

- Daily: Inspect hydraulic hoses, outriggers, and boom alignment.

- Monthly: Test overload sensors and lubrication systems.

- Annual: Structural integrity assessment for cracks or corrosion.

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: info@slkjcrane.com

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice