Ship Building Gantry Crane: Definition, Structure, and Working Principle

Ship Building gantry cranes are indispensable giants in the maritime industry, designed to handle ultra-heavy loads with precision in shipyard environments. These cranes play a pivotal role in assembling large ship components, such as hull blocks, engines, and deck machinery, ensuring efficiency and safety in complex manufacturing workflows. This article explores their definition, structural components, and working principles, shedding light on their critical role in modern shipbuilding.

Definition of a Shipbuilding Gantry Crane

A shipbuilding gantry crane is a specialized lifting machine featuring a gantry structure (a frame spanning over a workspace) equipped with hoists and trolleys. Unlike standard overhead cranes, these cranes are engineered to operate in harsh marine environments, with capacities ranging from 100 to 1,600+ tons and spans exceeding 150 meters. They are primarily used for:

- Lifting and positioning massive ship sections.

- Transporting prefabricated modules across dry docks.

- Supporting assembly processes in confined shipyard spaces.

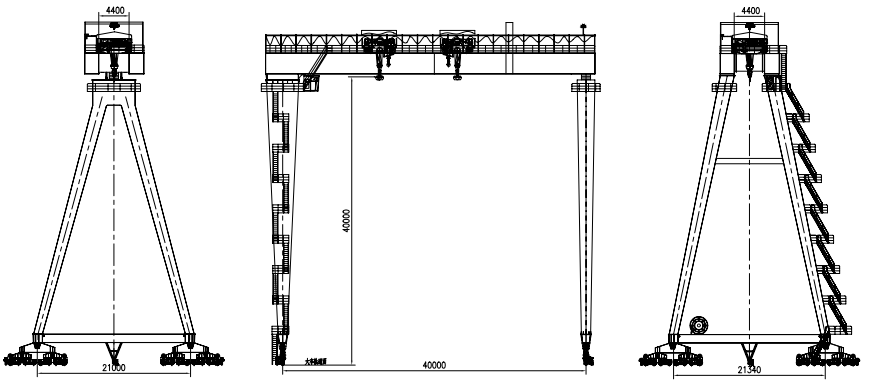

Structural Components

The robust design of shipbuilding gantry cranes ensures stability under extreme loads. Key structural elements include:

-

Main Gantry Frame:

- Composed of high-strength steel beams (box or truss designs) to withstand dynamic loads.

- Features a double-girder configuration for enhanced rigidity and load distribution.

-

Legs (Support Columns):

- Fixed or adjustable legs with rail-mounted bases for mobility along docks.

- Equipped with anti-collision sensors and wind-resistant bracing for coastal conditions.

-

Lifting Mechanism:

- Trolley System: Moves horizontally along the gantry beams, carrying hoists and hooks.

- Hoist Unit: Includes wire ropes, drums, and electric motors for vertical lifting.

- Spreaders: Customizable attachments (e.g., hydraulic grabs, magnetic lifts) for handling irregular ship parts.

-

Drive System:

- Electric motors powering wheels for longitudinal travel.

- Frequency-controlled drives ensure smooth acceleration and braking.

-

Control Cabin:

- Ergonomically designed for operator visibility, often with remote-control capabilities.

Working Principle

Beyond traditional shipyards, modern shipbuilding gantry cranes are adapting to new challenges:

- Automation: Integration with AI-driven logistics systems for real-time load tracking.

- Modular Designs: Prefabricated components enable rapid assembly in temporary shipyards.

- Green Technologies: Energy recovery systems and solar-powered operations reduce carbon footprints.

Conclusion

Shipbuilding gantry cranes are engineering marvels that combine brute strength with cutting-edge technology. Their ability to maneuver colossal ship components with millimeter precision makes them irreplaceable in the maritime sector. As shipbuilders embrace larger vessels (e.g., LNG carriers, offshore platforms) and sustainable practices, these cranes will continue to evolve, driven by innovations in automation, materials science, and energy efficiency.

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: info@slkjcrane.com

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice