Definition and Classification of Hoist Cranes

Hoist cranes are indispensable mechanical systems in industries requiring precise and efficient material handling. Combining vertical lifting capabilities with horizontal mobility, they are widely used in manufacturing, construction, logistics, and energy sectors. This article delves into the technical definitions, classifications, and practical applications of hoist cranes to guide businesses in selecting the optimal solutions for their operational needs.

Definition of Hoist Cranes

A hoist crane integrates two primary components:

- Hoist: The lifting mechanism (electric, hydraulic, or manual) that vertically moves loads via chains, wire ropes, or synthetic slings.

- Crane Structure: The framework (overhead, gantry, or jib-type) that supports horizontal movement and positioning.

This combination enables precise load handling in both vertical and horizontal planes, making hoist cranes ideal for tasks ranging from assembly line operations to heavy industrial lifting.

Classification of Hoist Cranes

Hoist cranes are categorized based on structural design, mobility, and application-specific features:

1 Overhead Hoist Cranes

-

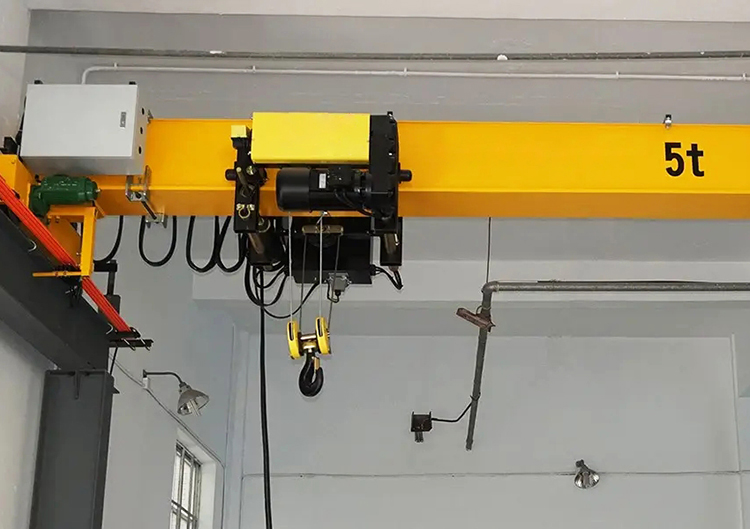

Single-Girder Overhead Cranes:

- Design: A single bridge beam supported by end trucks.

- Capacity: Typically handles light to medium loads (1–20 tons).

- Applications: Workshops, warehouses, and assembly lines.

- Advantages: Cost-effective, space-saving, and easy to install.

-

Double-Girder Overhead Cranes:

- Design: Two parallel bridge beams for enhanced stability.

- Capacity: Heavy-duty lifting (up to 550+ tons).

- Features: Equipped with low-headroom hoists to maximize vertical workspace.

- Applications: Steel mills, foundries, and large-scale manufacturing facilities.

2 Gantry Hoist Cranes

-

Full Gantry Cranes:

- Design: Freestanding structure with legs running on ground rails.

- Capacity: 5–450 tons.

- Applications: Outdoor storage yards, shipping ports, and heavy equipment handling.

-

Semi-Gantry Cranes:

- Design: One leg moves on a rail, while the other is anchored to a building.

- Advantages: Ideal for facilities with limited floor space.

- Applications: Small factories and maintenance bays.

-

Portable Gantry Cranes:

- Design: Lightweight, modular frames with adjustable spans.

- Capacity: 0.5–10 tons.

- Applications: Temporary lifting in construction sites or repair workshops.

3 Jib Hoist Cranes

Wall-Mounted Jib Cranes:

- Design: Fixed to walls or columns, covering a semi-circular work area.

- Capacity: 0.25–5 tons.

- Applications: Loading docks, machining centers, and assembly stations.

Freestanding Jib Cranes:

- Design: Self-supporting column with 360° rotation.

- Capacity: 0.5–15 tons.

- Applications: Precision lifting in confined spaces, such as automotive repair shops.

4 Specialized Hoist Cranes

-

Group-Hoist Systems:

- Design: Multiple synchronized hoists (e.g., DHP chain hoists) controlled via a central system.

- Precision: Synchronization error ≤ ±5 mm.

- Applications: Bridge construction, tank installations, and aerospace assembly.

-

Explosion-Proof Hoist Cranes:

- Design: Flame-resistant materials, spark-free motors, and anti-static components.

- Certifications: ATEX, IECEx.

- Applications: Oil refineries, chemical plants, and mining operations.

-

Marine Hoist Cranes:

- Design: Corrosion-resistant coatings (e.g., stainless steel) and SOLAS compliance.

- Applications: Cargo handling on ships, offshore platforms, and coastal facilities.

Key Applications by Industry

- Manufacturing: Transporting raw materials, positioning machinery components, and assembling products.

- Construction: Lifting steel beams, prefabricated modules, and concrete panels.

- Logistics: Loading/unloading containers and managing warehouse inventory.

- Energy: Installing wind turbines, maintaining nuclear reactors, and handling pipelines.

Emerging Trends (2024–2025)

- Energy Efficiency: Integration of VFDs (Variable Frequency Drives) reduces power consumption by 25–30%.

- Smart Technologies: IoT sensors enable real-time monitoring of load weight, motor temperature, and predictive maintenance.

- Lightweight Materials: High-strength alloys (e.g., Q345 steel) reduce crane weight without compromising load capacity.

- Safety Innovations: Centrifugal safety brakes and AR-based operator training minimize accident risks.

Choosing the Right Hoist Crane

- Load Capacity: Match hoist specifications (e.g., 1–550 tons) to operational demands.

- Workspace Constraints: Opt for low-headroom or compact designs in height-limited facilities.

- Environmental Conditions: Select corrosion-resistant or explosion-proof models for harsh environments.

- Customization: Modular systems allow tailored configurations for unique workflows.

Conclusion

Hoist cranes are versatile, high-performance solutions for modern industrial challenges. By understanding their classifications and aligning them with operational requirements, businesses can enhance productivity, safety, and cost-efficiency. For specialized applications, consult with certified manufacturers to design systems that meet exact technical and regulatory standards.

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: info@slkjcrane.com

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice