Types of Cranes: A Comprehensive Guide to Lifting Equipment

Cranes are indispensable machines across industries like construction, manufacturing, shipping, and energy. With diverse designs tailored to specific tasks, understanding the types of cranes and their applications ensures optimal project efficiency and safety. This guide explores the most common crane categories, their key features, and ideal use cases.

1. Mobile Cranes

Mobile cranes are versatile, self-propelled machines designed for quick setup and mobility.

a) Truck Mounted Cranes

- Features: Mounted on commercial truck chassis, equipped with telescopic booms and hydraulic systems.

- Applications: Roadside repairs, urban construction, and short-term projects.

- Capacity: 10–500 tons.

b) All-Terrain Cranes

- Features: Heavy-duty axles and 4×4 capabilities for rough terrain.

- Applications: Oil fields, mining, and remote infrastructure projects.

- Capacity: 50–1,200 tons.

c) Crawler Cranes

- Features: Tracked undercarriage for stability on soft ground; no outriggers needed.

- Applications: Large-scale construction (bridges, wind turbines).

- Capacity: 40–4,000+ tons.

d) Rough-Terrain Cranes

- Features: Compact with rugged tires and a single-engine design.

- Applications: Industrial plants, forestry, and military logistics.

- Capacity: 15–250 tons.

2. Fixed Cranes

Fixed cranes are permanently or semi-permanently installed structures ideal for repetitive tasks.

a) Overhead Bridge Cranes

- Features: Consist of parallel runways with a traveling bridge; operated via pendant or radio control.

- Types: Single girder (light-duty) and double girder (heavy-duty).

- Applications: Factories, warehouses, and assembly lines.

b) Gantry Cranes

- Features: Supported by A-frame legs on ground rails; includes full gantry, semi-gantry, and portable variants.

- Applications: Shipyards, container handling, and outdoor storage.

c) Tower Cranes

- Features: Tall, fixed structures with horizontal jibs; modular for on-site assembly.

- Applications: High-rise buildings and large infrastructure projects.

3. Specialized Cranes

These cranes are engineered for niche industries or extreme conditions.

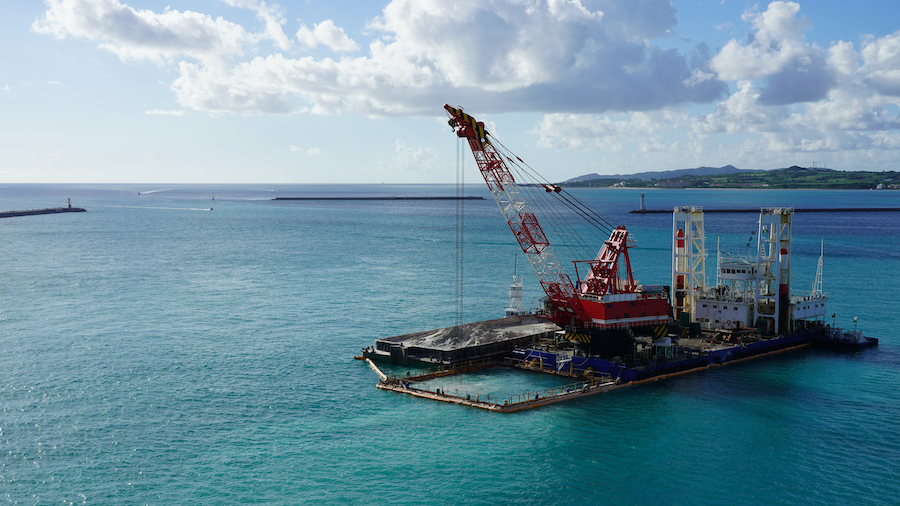

a) Floating Cranes

- Features: Mounted on barges or ships; equipped with rotating booms.

- Applications: Offshore oil rigs, port construction, and salvage operations.

b) Aerial Cranes

- Features: Helicopter-mounted lifting systems.

- Applications: Transporting heavy equipment to remote/inaccessible areas (e.g., mountain telecom towers).

c) Loader Cranes

- Features: Hydraulic knuckle booms mounted on trucks or trailers.

- Applications: Loading/unloading goods (e.g., timber, scrap metal).

d) Jib Cranes

- Features: Horizontal arm (jib) rotating on a vertical mast; wall-mounted or freestanding.

- Applications: Workshops, docks, and maintenance bays.

4. How to Choose the Right Crane

Consider these factors when selecting a crane:

- Load Capacity: Match crane capacity to maximum load weight.

- Workspace Constraints: Evaluate height limits, ground conditions, and mobility needs.

- Duty Cycle: Opt for heavy-duty cranes (e.g., double girder) for 24/7 operations.

- Regulations: Ensure compliance with OSHA, ANSI, or regional safety standards.

Conclusion

From mobile cranes tackling rugged terrains to towering giants shaping skylines, each crane type serves a unique purpose. By understanding their capabilities and limitations, businesses can enhance productivity, reduce downtime, and ensure worker safety.

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: info@slkjcrane.com

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice