Gantry Cranes in Highway and Bridge Construction: The Key Role in Industrialized Processes

Introduction

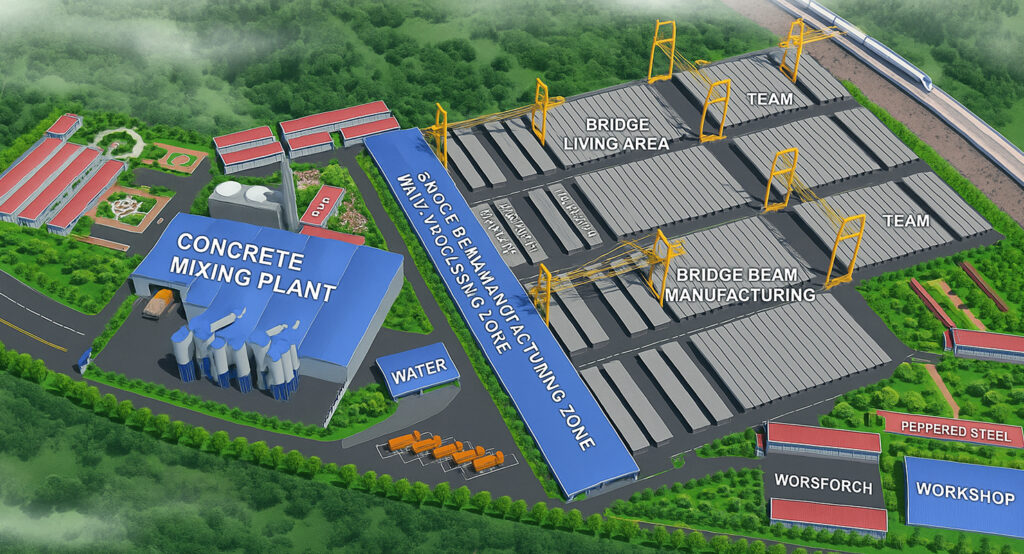

Modern highway and bridge construction has shifted from manual labor to an industrialized workflow. From rebar processing to precast beam manufacturing, transportation, and girder erection—gantry cranes and bridge erection equipment act as the central hubs that connect every phase.

These cranes, much like a heavy duty engine crane in a factory setting, combine precision, strength, and reliability. With professional crane engineering design and strong crane engineering sales support, SLKJCrane provides solutions that improve safety, efficiency, and return on investment.

Industrialized Construction Workflow and the Crane’s Core Role

1. Rebar Processing – Efficient Material Handling

In the rebar yard, tons of steel bars are cut, bent, and tied.

Crane Role: Lifting raw steel coils and transporting finished cages.

Performance: Cuts handling time by 70% and prevents deformation.

👉 Similar to an engine crane for sale, this ensures safer, faster operations.

2. Beam Yard – Precision Lifting of Molds and Precast Beams

Precast beams can weigh up to 100 tons.

Crane Role: Positioning molds, lifting cages, and moving beams.

Performance: Dual-girder cranes offer millimeter accuracy, boosting daily production by 30%.

Much like a harbor freight engine crane ensures precise handling in workshops, SLKJCrane’s solutions guarantee efficiency in beam production.

3. Beam Transportation – Safe Loading and Unloading

Crane Role: Loading beams onto carriers and unloading at site.

Performance: Doubles efficiency and reduces damage risk.

4. Girder Erection – The Project’s Critical Milestone

Crane Role: Hoisting precast beams onto piers with millimeter alignment.

Performance: Anti-sway & anti-wind control improves safety by 40%.

This precision comes from advanced crane engineering, just as in engine crane systems built for industrial applications.

5. Bridge Deck Construction – Heavy Component Handling

Crane Role: Lifting guardrails, steel structures, and drainage systems.

Performance: Reduces scaffolding and accelerates deck installation.

Road Surface Paving – Continuous Supply of Equipment and Materials

Crane Role: Moving large paving machines, rollers, and asphalt hoppers.

Performance: Keeps paving continuous and avoids delays.

Comprehensive Advantages of Gantry Cranes

Shortened Timeline – 20–50% faster across key phases.

Improved Safety – Anti-sway & smart positioning.

High Precision – Millimeter-level alignment.

All-Weather Adaptability – Reliable in any climate.

High ROI – Investment pays off in 1–2 large projects.

These benefits mirror the reliability of a heavy duty engine crane in manufacturing—robust, precise, and cost-efficient.

Case Study: Southeast Asia Highway Bridge Project

Two 160 ton gantry cranes from SLKJCrane lifted and installed over 300 beams (80 tons each).

Results:

Completed 3 weeks early

Zero lifting accidents

Saved $200,000 in labor and rental costs

Conclusion

In highway and bridge construction, gantry cranes are not just lifting tools—they are the core hubs that make industrialized workflows possible.

With SLKJCrane’s crane engineering expertise and strong crane engineering sales support, you gain efficiency, precision, and higher ROI. Whether for massive precast beams or industrial lifting, from harbor freight engine crane models to engine cranes for sale, the principle is the same: the right crane solution defines project success.

👉 Contact SLKJCrane Today for customized gantry crane solutions.

FAQ

Gantry cranes are essential for lifting and transporting precast beams, steel molds, rebar cages, and construction equipment. Similar to a heavy duty engine crane used in workshops, gantry cranes provide the strength and precision needed to keep large-scale projects safe and efficient.

Crane engineering focuses on advanced design features such as anti-sway systems, wind-resistant control, and millimeter-level positioning. These technologies reduce human error, improve lifting precision, and increase overall site safety. With the right crane engineering sales support, contractors can choose models that best fit their project requirements.

An engine crane (often found in workshops, sometimes known as a harbor freight engine crane) is designed for lifting car engines or machinery components, usually in the 1–3 ton range. A gantry crane, on the other hand, is an industrial solution capable of lifting 50–200 tons or more, making it ideal for heavy-duty tasks like precast beam erection in highway and bridge projects.

You can find engine cranes for sale in retail and industrial suppliers like Harbor Freight for smaller-scale lifting tasks. For large infrastructure projects, SLKJCrane provides customized gantry cranes for bridge and highway construction, backed by professional crane engineering sales and after-sales service.

Choosing high-quality lifting equipment ensures durability, safety, and efficiency. SLKJCrane’s solutions—from heavy duty engine cranes to large-scale gantry cranes—are designed to reduce project timelines, minimize risks, and deliver higher return on investment.

Yes. SLKJCrane gantry cranes are engineered to work in hot, humid, or low-temperature conditions. With advanced crane engineering features, they remain reliable under all weather conditions, just like a heavy duty engine crane designed for continuous industrial use.

Intermodal Gantry Cranes (RMG & RTG) — Engineering Playbook

Intermodal Gantry Cranes (RMG & RTG) — Engineering Playbook This engineering-oriented guide targets rail-to-truck operations, inland ports (ICDs),

Electric Hoist Gantry Crane: Complete Sizing & Selection Guide | SLKJCrane

Electric Hoist Gantry Crane: A Complete Sizing & Selection Guide Choosing the right electric hoist gantry crane comes

MG Double Girder Gantry Crane with Hook | Heavy-Duty Outdoor Lifting

MG Double Girder Gantry Crane with Hook: Structure, Specs & Applications An MG double girder gantry crane with

Steel Mill Wire Rope Lubrication for Metallurgical Hoists | Cut Downtime by 41%

Steel Mill Wire Rope Lubrication for Metallurgical Hoists: Root-Cause Fix & Proven Results Wire rope failures in steel

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice