Double Girder Overhead Crane: Types, Pricing, and How to Choose the Right Duty Class

Why Choosing the Right Overhead Crane Matters?

When upgrading a factory or investing in new lifting equipment, buyers often face three critical questions:

What types of double girder overhead cranes are available?

How much does a double girder overhead crane cost, and what factors affect the price?

How do you choose the right duty class (A3–A8) for your working conditions?

What is a Double Girder Overhead Crane?

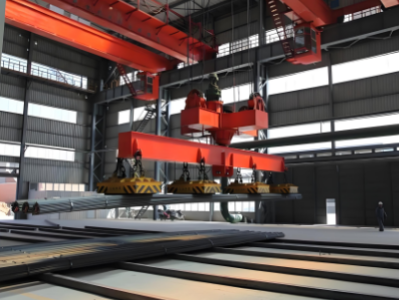

A double girder overhead crane, also known as a double girder bridge crane, is a heavy-duty lifting system widely used in industrial workshops, steel plants, ports, and warehouses.

It consists of:

Two parallel main girders connected by end trucks (bridge frame).

A trolley with hoist or winch that travels along the girders for cross movement.

The entire crane travels longitudinally on rails installed along the workshop columns.

Compared with a single girder overhead crane, a double girder model offers higher lifting capacity, larger span (over 40 meters), and more stable operation, making it ideal for medium to heavy loads and high-frequency usage.

Common Types of Double Girder Overhead Cranes

1. General-Purpose Cranes (LH / QD Type)

LH type double girder overhead crane:

Uses an electric hoist, lifting capacity 5–32 tons, duty class A3–A5, compact structure and low cost. Best for small and medium workshops handling machine parts and daily materials.

QD type double girder overhead crane:

Uses a winch, lifting capacity 10–600 tons, duty class A5–A8, with variable speeds. Suitable for heavy machinery assembly lines, steel plants, and large-scale production.

2. Special Cargo Handling Cranes

QZ type grab bucket crane:

Equipped with a grab bucket, designed for bulk materials such as coal, sand, or minerals in ports, mines, and water treatment plants.

QC type electromagnetic overhead crane:

With magnetic chuck for steel plates, scrap, and billets. Ideal for scrap yards and steel warehouses.

QB type explosion proof overhead crane:

Built with explosion-proof motors and control cabinets, used in chemical plants, oil depots, and flammable environments.

3. Customized Cranes for Harsh Environments

Anti corrosion overhead crane:

With fluorocarbon coating and stainless steel parts, suitable for electroplating plants, fertilizer factories, and coastal facilities.

High temperature double girder crane:

Heat resistant materials and insulated cabin, perfect for metallurgical workshops, casting plants, and glass furnaces.

Double Girder Overhead Crane Pricing: What Affects the Cost?

The price of a double girder overhead crane varies depending on multiple technical and service factors:

Core Parameters – Capacity & Span

A 5-ton LH type crane costs about $12,000–28,000.

A 50-ton QD type crane can reach $55,000–140,000.

Increasing span from 16 m to 30 m may raise the price by 30–50%.

Lifting Height & Speed

Raising height from 9 m to 24 m adds 15–20% to the price.

Adding variable frequency drive (VFD) for smooth speed control increases cost by 10–15%.

Special Configurations

Explosion-proof crane: 40–60% more expensive.

Anti-corrosion model: 25–35% more expensive.

Add-ons such as cabins, remote monitoring, or automation may add several thousand to tens of thousands of dollars.

Brand & After-Sales Service

Well-known brands are typically 15–25% higher in price but ensure better quality and spare parts.

Extended warranty (e.g., 3 years) adds another 8–12%.

👉 Standard general-purpose double girder cranes (5–20 tons, 16–22 m span) range $15,000–80,000, while customized heavy-duty cranes (e.g., 32-ton explosion-proof) may cost $100,000–200,000.

How to Choose the Right Duty Class (A3–A8)?

The working duty class defines how intensively the crane can operate:

| Duty Class | Usage Frequency | Load Condition | Application Example |

|---|---|---|---|

| A1–A4 (Light duty) | ≤ 4 hours/day | ≤ 50% rated load | Warehouses, occasional lifting |

| A5–A6 (Medium duty) | 4–8 hours/day | 50–75% rated load | Workshops, daily production |

| A7–A8 (Heavy/Extra heavy duty) | ≥ 8 hours/day | ≥ 75% rated load | Ports, steel plants, 24/7 operations |

Practical Selection Tips:

Harsh environments (high temperature, dust, corrosive): increase duty class by 1 level.

High-risk operations (molten steel, flammable materials): choose A6 or above.

Long-term investment (10+ years use): at least A5 class.

By matching the duty class with your operation frequency, load, and environment, you ensure long service life, higher efficiency, and reduced downtime.

Why Choose SLKJCrane?

The working duty class defines how intensively the crane can operate:

SLKJCrane has 10+ years of experience in designing and manufacturing customized double girder overhead cranes. We provide:

Tailored solutions based on capacity, span, and working class.

On-site survey and professional selection guidance.

Competitive pricing with reliable after-sales service.

📩 Contact our engineers today to get a free consultation and quotation for your project.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen Hu

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

Frequently Asked Questions (FAQ) About Double Girder Overhead Cranes

A single girder crane is more cost-effective but limited in span and capacity. A double girder crane supports heavier loads, larger spans, and higher duty classes (A5–A8).

Typically between $18,000–35,000, depending on span, lifting height, and speed control system.

At least A6–A8, due to continuous heavy-duty operation and harsh working environment.

Yes, with anti-corrosion paint, stainless steel parts, and weatherproof enclosures for outdoor ports or coastal applications.

Normally 30–60 days for standard cranes, and 60–90 days for customized large-tonnage or special cranes.

Workshop Small Lifting Equipment Guide | Electric Hoists, Jib Cranes, Gantry Cranes

Complete Guide to Workshop Small Lifting Equipment: Electric Trolley, Electric Hoist, Winch, Jib Crane & Lightweight Gantry Crane

Small Portable Gantry Crane | Indoor & Mobile Lifting Solutions by SLKJCrane

Industrial Lightweight Lifting Solution: How to Choose and Use a Small Portable Gantry Crane What Is a Small

Double Girder Overhead Crane: Types, Price & Duty Class Guide

Double Girder Overhead Crane: Types, Pricing, and How to Choose the Right Duty Class Why Choosing the Right

Gantry Crane Operation Guide | Safe Use, Inspection & Training – SLKJCrane

Gantry Crane Operation Guide: Avoid Common Mistakes and Improve Safety Are You Operating Your Gantry Crane Safely? Many

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Tel: +8615738677559

E-mail: info@slkjcrane.com

Whatsapp: +8615738677559

Address: Crane Industry Park, Xinxiang City Henan Provice