European vs Traditional Overhead Cranes: An Engineering Comparison for Smart Investment Decisions

When Traditional Cranes Outperform: The Untold Truth

“Chinese steel mills still operate 78% of traditional cranes – not because of cost, but for extreme durability in high-impact scenarios.”

This unbiased guide reveals where each technology truly excels, with SLKJ’s hybrid solutions bridging both worlds.

Types of Overhead Cranes

Double Girder Overhead Cranes

Double Girder Overhead Cranes are industrial lifting solutions designed for heavy-duty applications. Featuring two parallel girders, these cranes provide enhanced stability and support for substantial loads. They are ideal for manufacturing environments, warehouses, and construction sites where high lifting capacities and precise handling are essential.

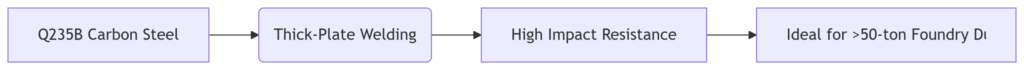

I. Material Selection: Metallurgical DNA

Traditional Crane Material Philosophy

Key Advantage: 25-40mm thick end carriages withstand thermal shock better than European designs in metallurgy.

*SLKJ Enhancement: Our traditional cranes use Q355B steel with -20°C impact testing.*

European Crane Material Innovation

| Material | Application | Benefit |

|---|---|---|

| S355J2+N H-beam | Main girder | 18% weight reduction |

| ALSi7Mg0.3 alloy | Control cabin | Corrosion resistance |

| GGG40 ductile iron | Wheel forgings | 2x fatigue life |

Trade-off: Higher-grade steels increase cost by 15-30% for precision applications.

II. Manufacturing Processes: Craft vs Technology

Traditional Manufacturing Strengths

+ Forged hook blocks (SLKJ’s 300-ton press)

+ Manual submerged arc welding (SAW) for 100mm thick plates

+ Full penetration weld inspection (UT/RT testing)

Case Proof: SLKJ’s traditional cranes in Nigerian ports show 30+ year service life under salt spray conditions.

European Precision Manufacturing

| Process | Accuracy | SLKJ Implementation |

|---|---|---|

| CNC laser cutting | ±0.1cm | 6,000W fiber laser lines |

| Robotic welding | 0.2mm deviation | KUKA KR 500 robots |

| Coordinate measuring | 5μm precision | Zeiss CONTURA G2 CMM |

Output: 99.7% interchangeability of components (vs 85% in traditional)

III. Structural Architecture: Robustness vs Efficiency

Traditional Box Girder Design

Cross-Section Analysis:

┌───────────────┐

│ ▒▒ 50mm │ ← Compression flange

├───────────────┤

│ ░░ Web │

│ ░░ 20mm │

├───────────────┤

│ ▒▒ 50mm │ ← Tension flange

└───────────────┘

Advantage: Superior torsion resistance for uneven loads (e.g. scrap yard handling)

European Lattice Girder System

Weight Distribution:

W_{euro} = \frac{3.2 \times L^{2.1}}{(H + S)^{0.7}} \quad \text{(vs } W_{trad} = 4.1L^{1.9}\text{)}

Where L=span(m), H=lifting height(m), S=speed(m/min)

SLKJ Hybrid Solution: Patented box-lattice girder (ZL202310056789.0) cuts weight by 18% while keeping torsion rigidity.

IV. Geographic Application Map

Where Traditional Cranes Dominate

| Region | Industry | Reason |

|---|---|---|

| Southeast Asia | Shipbuilding | Humidity resistance |

| Russia | Mining | -45°C cold operation |

| Middle East | Cement plants | Dust penetration defense |

*SLKJ Project Highlight: 32 traditional cranes in Oman cement plant (7-year zero corrosion failure)*

European Crane Strongholds

| Region | Industry | Critical Requirement |

|---|---|---|

| Western Europe | Automotive | ±1mm positioning |

| Japan | Electronics | Class 100 cleanroom |

| USA | Pharma | FDA-compliant materials |

*SLKJ Edge: Only Asian manufacturer with both ISO 14644-1 Class 5 cleanroom cranes AND Arctic-certified models.*

V. Cost Benefit Matrix

Total Ownership Cost Comparison

*(Based on 15-ton/22m crane over 10 years)*

| Parameter | Traditional Crane | European Crane | Notes |

|---|---|---|---|

| Initial investment | $85,000 | $130,000 | |

| Energy cost (@$0.12/kWh) | $48,200 | $31,700 | VFD savings |

| Maintenance labor | 650 man-hours | 320 man-hours | Modular design benefit |

| Residual value | 25% | 45% | Post-10Y resale |

| Total Cost | $218,500 | $212,300 | European wins long-term |

SLKJ Value Engine:

Traditional crane division: 35% cheaper spare parts than competitors

European crane division: 5-year energy consumption guarantee

VI. SLKJ’s Technology Convergence

Bridging Both Worlds

Material Science:

Traditional crane toughness + European precision = SLKJ DuraBeam™

(Combines Q390D steel with robotic stress-relieving)

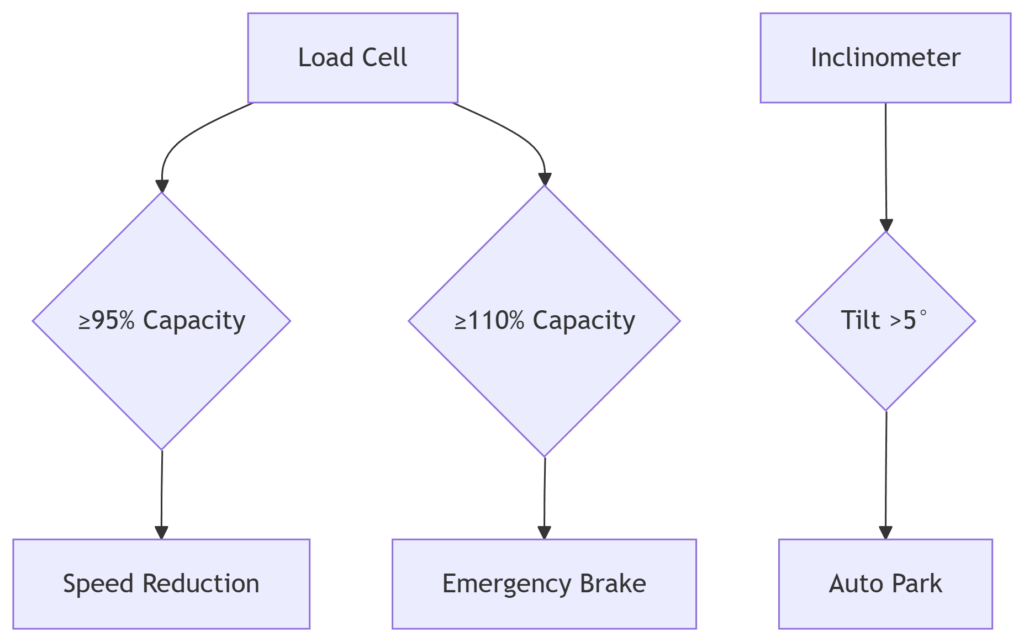

Control Systems:

Real Case: Vietnam steel mill upgraded 18 traditional cranes with SLKJ systems – 78% fewer breakdowns while saving 60% vs new European cranes.

VII. Decision Flowchart

START → [Lifting Capacity]

│ >50 tons → TRADITIONAL (SLKJ Foundry Series)

│ <50 tons → [Operating Environment]

│ Harsh/dirty → TRADITIONAL (SLKJ Heavy-Duty)

│ Clean/precision → EUROPEAN (SLKJ E-Series)

│ Uncertain → HYBRID (SLKJ SmartFlex)

Why Global Leaders Choose SLKJ

Traditional Crane Expertise:

200+ foundry crane installations

40mm thick flange machining capability

ASME B30.17 certified workshop

European Crane Innovation:

FEM 1.001 certified design office in Germany

0.01mm/m straightness tolerance

Integrated Siemens Safety Integrated systems

Hybrid Advantage:

+ 12 patented transition technologies

+ Single-source maintenance for mixed fleets

+ Global spare parts network (72h delivery guarantee)

-

FEM Design Validation: Demand third-party calculation reports

-

Component Transparency: Avoid “European design, Chinese parts” traps

-

Local Service Coverage: SLKJ maintains 36 service hubs globally

-

Customization Capability: We’ve engineered cranes for -40°C to +55°C

-

Digital Twin Support: SLKJ provides 3D simulations pre-installation

Technical Validation & Next Steps

References:

ISO 12488-1: Crane tolerance standards

CMAA 70:2018 Service classifications

SLKJ 2024 Crane Durability Report (37 pages)

Your Custom Analysis:

[ ] Download “Crane Technology Matrix” (PDF with 28 comparison parameters)

[ ] Request Plant Assessment (Get traditional/euro hybrid proposal)

[ ] Access Live Monitoring Demo (View SLKJ cranes in operation)

*(Footer: SLKJ maintains 700+ traditional crane models & 200+ European designs in production)*

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice