A Deep Dive into Double Girder Overhead Crane Types and Innovations

Understanding Common Challenges in Selecting Double Girder Overhead Cranes

When it comes to heavy lifting in industrial applications, double girder overhead cranes stand out as a robust solution. However, potential buyers often encounter several challenges when selecting the right crane for their specific operational needs. Common questions may revolve around lifting capacity, span length, lifting height, and the specific features needed for unique applications. This article will address these concerns and provide comprehensive insights into the types, specifications, and innovations surrounding double girder overhead cranes, enabling you to make informed decisions.

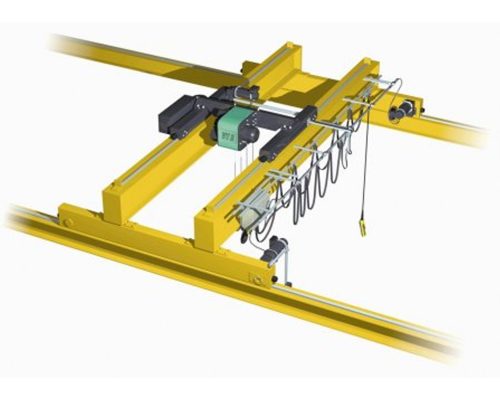

What is a Double Girder Overhead Crane?

A double girder overhead crane, also known as a double girder bridge crane or double girder EOT (Electric Overhead Traveling) crane, features two parallel beams that provide superior lifting capabilities compared to single girder models. Because they are designed for heavy-duty applications, double girder cranes are comprised of more complex components, which can make them a more significant investment.

Core Components of a Double Girder Overhead Crane

- Bridge Girders: The primary support structure that carries the weight of the load.

- End Trucks: The parts that allow the crane to move along the runway.

- Hoist Assembly: The mechanism responsible for lifting and lowering the load.

Double Girder Overhead Crane Types

LH Type Double Girder Overhead Crane With Hoist Trolley

- Capacity: 5-32/5 tons

- Span Length: 10.5-31.5 m

- Lifting Height: 3-20 m

- Work Duty: A3, A4

- Rated Voltage: 220V – 690V, 50-60Hz, 3-phase AC

- Operating Conditions: Temperature range of -25℃ to +50℃, relative humidity ≤85%

Specifications Table for LH type Double Girder Overhead Cranes

| Capacity (t) | Span (m) | Lifting Height (m) | Lifting Speed (m/min) | Working Duty | Total Power (kW) | Price ($) |

|---|---|---|---|---|---|---|

| 5 | 10.5-31.5 | 16 | 12.5/15.5 | A5, A6 | 22.8-27.8 | 15,600−15,600 – 15,600−29,500 |

| 10 | 10.5-31.5 | 16 | 8.5/3.2 | A5, A6 | 26.8-34.8 | 17,200−17,200 – 17,200−32,500 |

| 20 | 10.5-31.5 | 12/14 | 7.2/9.7 | A5, A6 | 55.6-69.0 | 25,500−25,500 – 25,500−45,900 |

| 32 | 10.5-31.5 | 14/16 | 6.0/7.4 | A5, A6 | 71.3-86.3 | 36,200−36,200 – 36,200−59,800 |

QD Type Double Girder Overhead Crane With Winch Trolley

- Capacity: 5-800/150 tons

- Span Length: 10.5-31.5 m

- Lifting Height: 3-50 m

- Work Duty: A5, A6

- Rated Voltage: 220V – 690V, 50-60Hz, 3-phase AC

- Operating Conditions: Temperature range of -25℃ to +50℃, relative humidity ≤85%

Specifications Table for QD-type Double Girder Overhead Cranes

| Capacity (t) | Span (m) | Lifting Height (m) | Lifting Speed (m/min) | Working Duty | Total Power (kW) | Price ($) |

|---|---|---|---|---|---|---|

| 5 | 10.5-31.5 | 16 | 12.5/15.5 | A5, A6 | 22.8-27.8 | 15,600−15,600 – 15,600−29,500 |

| 10 | 10.5-31.5 | 16 | 8.5/3.2 | A5, A6 | 26.8-34.8 | 17,200−17,200 – 17,200−32,500 |

| 50 | 10.5-31.5 | 12/16 | 5.0/6.1 | A5, A6 | 93.5-110.5 | 49,500−49,500 – 49,500−72,000 |

| 100 | 13-31 | 18/20 | 3.1/3.9 | A5, A6 | 136-174 | 115,000−115,000 – 115,000−166,700 |

For more detailed specifications, refer to SLKJCrane’s catalog of LH-type and QD-type double girder overhead cranes.

Innovative Solutions and Applications

Double girder overhead cranes not only serve general lifting needs but also adapt to various industrial scenarios thanks to their customizable configurations. Here are a few notable innovations and applications:

QE Double Trolley Metallurgical Crane

- Application: Primarily for transporting scrap steel ladles in steel plants.

- Specifications:

- Lifting Capacity: 320 tons + 80 tons

- Span: 21.5 m

- Lifting Height: 22 m

- Operating Duty: A7

Safety Features

This crane includes safety protocols like short circuit protection, overload protection, and an advanced control system to maintain unlifting stability.

QD Fully Automatic Unmanned Overhead Crane

- Application: Designed for vanadium product factories, efficiently lifts and positions materials with minimal human intervention.

- Specifications:

- Lifting Capacity: 4 tons

- Span: 13.5 m

- Lifting Height: 9 m

- Operating Mode: Fully automatic

Technical Innovations

Equipped with anti-sway control systems and real-time monitoring, this system ensures precise operations, enhancing overall efficiency and safety.

QC Upper Rotating Electromagnetic Crane

- Application: Ideal for handling standard-length steel.

- Specifications:

- Capacity: 12.5 tons + 12.5 tons

- Span: 31.5 m

- Lifting Height: 10 m

- Work Duty: A7

Special Features

Utilizes an electromagnetic beam for lifting while enabling horizontal rotation, making it especially useful in steel distribution centers.

Selecting the Right Double Girder Overhead Crane

When choosing between different types of double girder overhead cranes, consider:

- Capacity Needs: Match the lifting capacity with your operational demands.

- Span and Height Requirements: Ensure the crane can fit and operate within the required space.

- Duty Cycle: Choose a crane that aligns with the work environment and frequency of operation.

- Special Features: Evaluate any additional features that may enhance safety or operational efficiency based on your industry specifics.

Comparing Double Girder to Single Girder Overhead Cranes

| Parameter | Single Girder Overhead Cranes | Double Girder Overhead Cranes |

|---|---|---|

| Lifting Capacity | 1-32 tons | 5-800 tons |

| Work Duty | A1-A5 | A3-A8 |

| Span Length | 7.5-31.5 m | 10.5-40.5 m |

| Lifting Height | 6-20 m | 12-28 m |

| Lifting Speed | 0.32-8 m/min | 0.63-63 m/min |

| Trolley Travelling Speed | 3.2-40 m/min | 10-63 m/min |

Why Choose SLKJ Crane for Your Double Girder Overhead Crane Solutions?

At SLKJ Crane (www.slkjcrane.com), we pride ourselves on offering tailored solutions for all types of overhead cranes. Our team of specialists is equipped to help you navigate the complexities of crane selection, ensuring that you get the most reliable and efficient lifting solutions for your business needs. Our commitment to quality and safety means that we comply with all industry standards, ensuring that you receive a product that meets your operational requirements.

FAQ

If you are in the market for a double girder overhead crane or need expert advice tailored to your specific lifting requirements, don’t hesitate to reach out to us. Our dedicated team is here to assist you in selecting the ideal crane and ensuring its seamless integration into your operations.

The main difference between single girder and double girder overhead cranes lies in their design and lifting capacities. A single girder crane has one supporting beam, making it lighter and suitable for lower lifting capacities (typically 1-20 tons). In contrast, a double girder crane features two parallel beams, providing superior strength, stability, and lifting capabilities (5-800 tons), making it ideal for heavy-duty applications.

Double girder overhead cranes can accommodate a wide range of lifting capacities, typically from 5 tons to over 800 tons. The specific capacity required depends on the application you are considering and the weight of the loads you need to lift.

There are several control modes available for double girder overhead cranes, including:

- Floor Control: Operators control the crane from the ground level using buttons or levers.

- Remote Control: A handheld device allows the operator to control the crane's movements from a distance.

- Cabin Control: A control cabin is built into the crane, providing the operator a vantage point to monitor and control the crane's operation effectively.

The span length for a double girder overhead crane is typically determined by the structure of the building and the operational layout. You need to measure the distance between the runway beams where the crane will operate. The span must accommodate the distance and any additional clearance for lifting operations. Consult with a crane specialist to ensure you select the appropriate span length for your application's specific needs.

Yes, double girder overhead cranes can be customized to meet specific application requirements. You can choose different lifting devices, trolley designs, and safety features tailored to your operational environment, such as high-temperature or hazardous areas. Discuss your requirements with SLKJ Crane to explore custom solutions that fit your industry needs.

When selecting a double girder overhead crane, look for safety features such as:

- Overload Protection: Prevents lifting loads exceeding the maximum capacity.

- Emergency Stop System: A quick-access button to halt the crane in emergencies.

- Travel Limit Switches: Prevents the crane from moving beyond designated limits.

- Safety Switches: Ensures that the crane cannot operate unless conditions are safe.

- Electronic or Mechanical Hoist Brakes: Provides secure stopping when lifting or lowering loads.

Regular maintenance is crucial for the longevity and safety of your double girder overhead crane. Recommended practices include:

- Routine Inspections: Check for any wear or damage on cables, hooks, and other components.

- Lubrication: Ensure that moving parts are well-lubricated to prevent friction and wear.

- Load Testing: Perform load tests periodically to ensure the crane operates within its specified limits.

- Electrical System Checks: Inspect wiring, control systems, and safety devices for proper functionality.

- Documentation: Keep accurate records of all maintenance activities and inspections for safety compliance.

To discuss your crane needs or request a quotation, you can reach out to SLKJ Crane through our website at www.slkjcrane.com or call our dedicated customer service team directly. We are here to assist you with any inquiries you may have regarding double girder overhead cranes or other lifting solutions!

Intermodal Gantry Cranes (RMG & RTG) — Engineering Playbook

Intermodal Gantry Cranes (RMG & RTG) — Engineering Playbook This engineering-oriented guide targets rail-to-truck operations, inland ports (ICDs),

Electric Hoist Gantry Crane: Complete Sizing & Selection Guide | SLKJCrane

Electric Hoist Gantry Crane: A Complete Sizing & Selection Guide Choosing the right electric hoist gantry crane comes

MG Double Girder Gantry Crane with Hook | Heavy-Duty Outdoor Lifting

MG Double Girder Gantry Crane with Hook: Structure, Specs & Applications An MG double girder gantry crane with

Steel Mill Wire Rope Lubrication for Metallurgical Hoists | Cut Downtime by 41%

Steel Mill Wire Rope Lubrication for Metallurgical Hoists: Root-Cause Fix & Proven Results Wire rope failures in steel

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice