The 5- on Watershed: Golden Rules for Selecting FEM Wire Rope Hoists vs. Chain Hoists

Electric hoists are among the most widely used light-duty lifting devices in industrial sectors. They play a crucial role in assembly, manufacturing, logistics, and construction. Within this field, FEM standard wire rope hoists and chain hoists stand out as two mainstream solutions. Both are proven, reliable technologies, yet they serve different application needs.

This article explores the core differences between wire rope and chain hoists, explains why 5 tons is the watershed capacity separating them, and provides golden selection rules to help buyers and engineers make the right decision.

1. Basic Principles and Characteristics

To understand the selection criteria, it’s essential to compare the structural and performance attributes of the two hoist types:

| Comparison Dimension | FEM Wire Rope Hoist | FEM Chain Hoist |

|---|---|---|

| Load Bearing Medium | Steel wire rope | Alloy steel chain |

| Capacity Range | 0.5 – 100 tons | 0.25 – 10 tons |

| Lifting Height | > 30 m (single rope) | Usually < 12 m |

| Lifting Speed | 8 – 20 m/min | 3 – 8 m/min |

| Structure | With drum, rope guide, relatively complex | Compact, simple design |

| Typical Application | Heavy loads, long lifting heights, fast operation | Tight spaces, medium loads, precise positioning |

Wire rope hoists are engineered for larger loads, higher lifting heights, and faster speeds. They typically integrate advanced drums and rope guidance systems, making them ideal for demanding industrial production.

Chain hoists, by contrast, are valued for their compactness, durability, and easy maintenance. They are particularly suitable for confined spaces, moderate loads, and situations where micro-movement control is important.

2. Why “5 Tons” Is the Watershed

Industry practice shows that 5 tons is the dividing line between chain and wire rope hoists. The reasons are grounded in material science, transmission design, and cost-efficiency:

Material Strength and Safety Factors

-

At ≤5 tons, chains offer strong tensile capacity with manageable thickness (8–10 mm).

-

Above 5 tons, chains become overly heavy, reducing efficiency and safety. Wire rope, with smaller diameter (6–8 mm), handles heavier loads better.

Transmission System Design

• Chain hoist gearboxes are typically optimized up to 5 tons. Beyond this, gearbox size and weight grow disproportionately.

• Wire rope systems with drums and sheaves provide a more cost-effective solution at higher capacities.

Economic Considerations

• Below 5 tons: Chain hoists are more affordable, require less maintenance, and offer quick installation.

• Above 5 tons: Wire rope hoists deliver higher value by balancing load, speed, and long-term durability.

Application Scenarios

-

<5 tons: Precision assembly, repair workshops, and maintenance jobs.

-

>5 tons: Warehouses, production lines, construction sites, and heavy-duty industrial lifting.

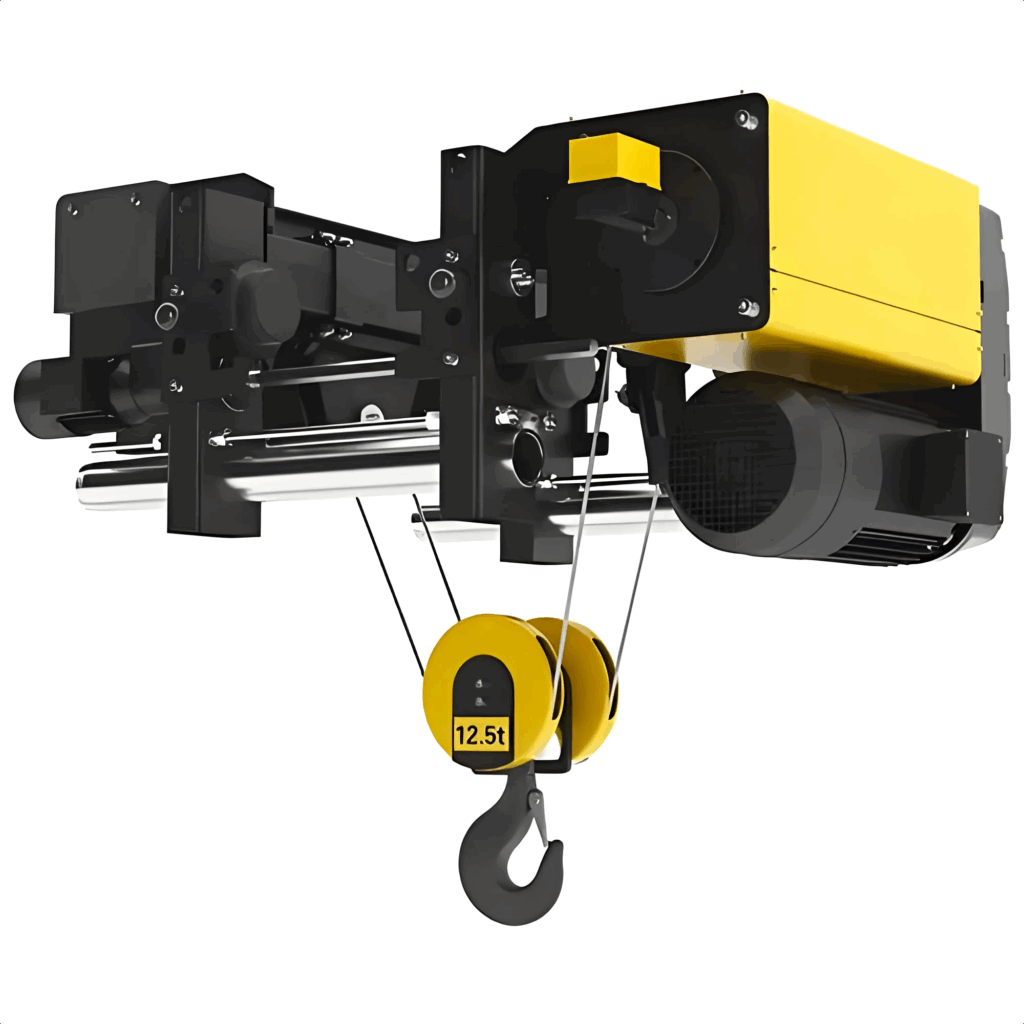

(FEM Standard Wire Rope hoist Application)

3. Golden Rules of Selection

When selecting the right hoist, engineers and buyers should follow these principles:

1. Load Capacity Priority

-

≤ 5 tons: Prefer FEM chain hoists.

-

≥ 5 tons: Choose FEM wire rope hoists.

2. Work Environment

-

Corrosive or humid conditions: Stainless steel chains or galvanized wire rope.

-

High temperature: Special alloys for chains or heat-resistant wire rope.

-

Hazardous or explosive zones: Explosion-proof motors and certified electrical systems.

3. Space Constraints

-

Limited horizontal space: Chain hoists are more compact.

-

Limited vertical headroom: Wire rope hoists can be customized for low headroom

4. Frequency of Use and Lifespan

-

Heavy-duty operation (≥8 hours/day): Wire rope hoists provide longer service life and fewer downtimes.

-

Occasional or low-frequency use: Chain hoists are cost-effective and easy to maintain.

5. Precision Requirements

-

Precision positioning: Chain hoists offer finer micro-movement control.

-

General lifting: Wire rope hoists deliver higher lifting efficiency.

4. Maintenance and Safety Considerations

Regardless of the choice, proper maintenance is critical to ensure reliability and safety:

-

Weekly inspections for broken wire strands or chain corrosion; replace if damaged.

-

Regular lubrication of gears, chains, and ropes using manufacturer-recommended grease.

-

Never exceed rated capacity; always confirm overload protection devices are functional.

-

Monthly no-load and full-load tests to verify braking and control performance.

-

Operators must be professionally trained, certified, and familiar with FEM duty classification standards.

5. Why Choose SLKJCrane?

At SLKJCrane, we specialize in manufacturing both FEM-standard wire rope hoists and chain hoists. With decades of engineering experience, we help clients worldwide choose the right hoist for their application, whether it’s a 5-ton workshop hoist or a 100-ton production hoist system.

By partnering with us, you benefit from:

-

Reliable FEM-compliant design and testing.

-

Customized solutions for load, speed, and environment.

-

Professional installation and after-sales support.

Choosing SLKJ hoists means choosing safety, efficiency, and peace of mind.

📩 Contact our engineers today to discuss your project requirements and get a tailored quotation.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen Hu

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

FAQ

At 5 tons, chain hoists become heavier and less efficient, while wire rope hoists handle higher loads more safely and cost-effectively.

Chain hoists are ideal for applications requiring precise positioning and micro-movement control, such as assembly or repair workshops.

Chain hoists are suitable for low-to-medium frequency use. For continuous or high-duty cycles, FEM wire rope hoists are recommended.

FEM classifications (e.g., M4, M5) define usage cycles and lifespan. For heavy production environments, choose a higher classification like M5.

Perform weekly inspections, lubricate parts regularly, avoid overloading, test brakes monthly, and ensure operators are trained and certified.

Intermodal Gantry Cranes (RMG & RTG) — Engineering Playbook

Intermodal Gantry Cranes (RMG & RTG) — Engineering Playbook This engineering-oriented guide targets rail-to-truck operations, inland ports (ICDs),

Electric Hoist Gantry Crane: Complete Sizing & Selection Guide | SLKJCrane

Electric Hoist Gantry Crane: A Complete Sizing & Selection Guide Choosing the right electric hoist gantry crane comes

MG Double Girder Gantry Crane with Hook | Heavy-Duty Outdoor Lifting

MG Double Girder Gantry Crane with Hook: Structure, Specs & Applications An MG double girder gantry crane with

Steel Mill Wire Rope Lubrication for Metallurgical Hoists | Cut Downtime by 41%

Steel Mill Wire Rope Lubrication for Metallurgical Hoists: Root-Cause Fix & Proven Results Wire rope failures in steel

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice