VFD Crane vs. Traditional Cranes: Energy Consumption Compared

In today’s industrial landscape, energy efficiency is a significant concern. Companies are constantly seeking ways to reduce operational costs while enhancing productivity. This article explores the energy consumption of variable frequency drive (VFD) cranes compared to traditional cranes. We will analyze the pros and cons of each system, delve into energy-saving potentials, and share successful case studies that highlight the benefits of VFD technology in bridge and gantry cranes.

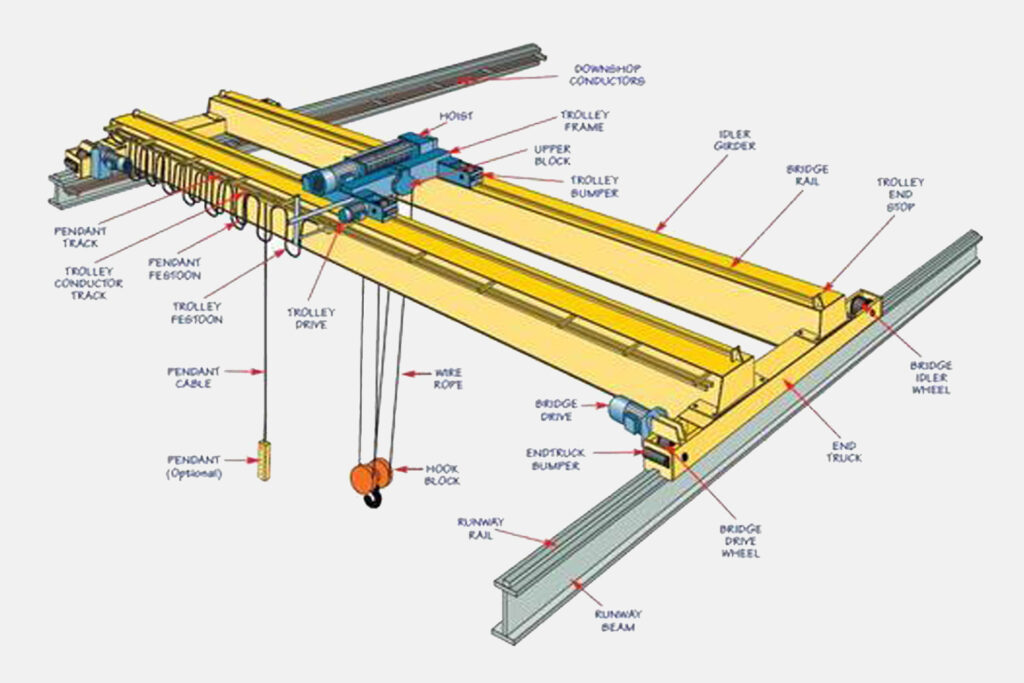

Understanding the Basics of Crane Technology

What Are Traditional Cranes?

Traditional cranes, often referred to as standard cranes, operate at fixed speeds. They utilize a straightforward electrical motor system that does not adjust to the actual load being lifted, which often leads to inefficiencies. The lack of flexibility in motor control can result in increased energy expenditures, especially in industries where load weight varies significantly.

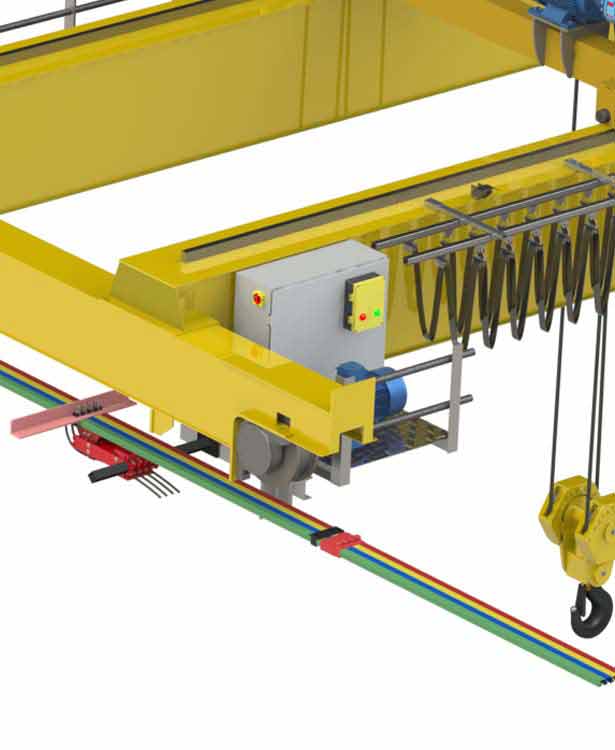

What Are Variable Frequency Drive Cranes?

Variable frequency drive cranes equip electric motors with VFD technology, allowing for speed control by adjusting the motor’s frequency. This capability enables the crane to match the speed to the load being lifted, creating a more energy-efficient operation. VFD cranes are innovative solutions for modern manufacturing and construction applications, especially where dynamic load changes are common.

Energy Consumption Comparison

Energy Efficiency Analysis

When comparing energy consumption, VFD cranes typically exhibit substantial advantage over traditional cranes. Studies indicate that VFD cranes can save energy by 30-50% compared to their traditional counterparts.

Factors Affecting Energy Consumption

Load Variability: Traditional cranes consume the same amount of power regardless of the load weight, leading to wasteful energy use. VFD cranes adjust power consumption based on load, optimizing energy use.

Operational Speed: VFD cranes allow for controlled acceleration and deceleration, reducing the energy spikes associated with traditional cranes that start and stop abruptly.

Standby Power: Traditional cranes often draw power even when not in use; VFD cranes can be programmed to enter a sleep mode, further reducing energy costs.

Practical Application Example: Energy Savings in a Manufacturing Facility

Consider a manufacturing facility that switched from traditional cranes to VFD cranes. By analyzing before and after energy consumption data, the facility noted an average monthly energy savings of 3,000,translatingtoanannualsavingsof3,000, translating to an annual savings of 3,000,translatingtoanannualsavingsof36,000. This case exemplifies the tangible benefits of transitioning to variable frequency drive systems.

Benefits of Variable Frequency Drive Cranes

Enhanced Control and Precision

One of the primary advantages of VFD cranes is the enhanced control they offer. Operators can perform precise movements that reduce the risk of accidents and materials damage. The ability to control speed finely aligns with operational needs, especially in sensitive applications.

Increased Lifespan of Equipment

By reducing the mechanical stress associated with sudden stops and starts, VFDs contribute to extending the lifespan of crane components. This leads to lower maintenance costs and decreases the frequency of equipment replacement.

Improved Work Environment

Operators often prefer working with VFD cranes due to the smoother operation and reduced noise levels. A quiet and stable environment can lead to improved focus and productivity.

Case Study: Transitioning to Variable Frequency Drives

Background

A construction company specializing in heavy materials handling made the decision to transition from traditional cranes to VFD-equipped bridge cranes. The reasons included:

- Rising energy costs

- Safety concerns

- Need for greater operational efficiency

Implementation

The company conducted a thorough analysis of existing operational procedures and identified opportunities for VFD integration. Training sessions were held for operators to ensure smooth adaptation to the new technology.

Results

- Energy Savings: After the transition, the company reported a 40% reduction in energy costs, equating to approximately $50,000 yearly.

- Increased Productivity: With better load management, the cranes could handle loads more efficiently, contributing to a 20% increase in overall project timelines.

Conclusion

The comparison of variable frequency drive cranes versus traditional cranes highlights significant advantages in energy consumption and operational efficiency. The ability of VFD technology to adjust energy use based on specific load requirements leads to considerable cost savings, increased safety, and a better work environment.

Investing in VFD cranes not only aligns with modern energy efficiency goals but also demonstrates a commitment to sustainability and innovation. As industries increasingly focus on reducing carbon footprints and operational costs, the switch from traditional to VFD cranes could very well provide a critical competitive edge.

Call to Action

For companies looking to enhance their lifting operations, consider evaluating the benefits of variable frequency drive cranes. Implementing this technology can lead to substantial energy savings, improved performance, and a safer work environment. Connect with us today to learn more about optimizing your crane operations with VFD technology.

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice