Total Cost of Ownership (TCO) Analysis for Bridge Cranes

The cost of bridge cranes is a significant consideration for companies engaged in industrial operations requiring heavy lifting solutions. When contemplating the acquisition of a bridge crane, it is essential to look beyond the initial purchase price and carefully analyze the total cost of ownership (TCO). This article delves deep into the components that contribute to TCO, offering insights into how businesses can optimize their investments in bridge cranes over their entire lifecycle.

What is Total Cost of Ownership (TCO)?

Defining TCO

Total Cost of Ownership (TCO) provides a comprehensive assessment of all costs associated with owning and operating a piece of machinery, in this case, a bridge crane. TCO includes not just the upfront purchase fee but also operational, maintenance, and end-of-life disposal expenses.

Importance of Understanding TCO

By understanding TCO, businesses can make informed decisions that pave the way for increased operational efficiency. Evaluating TCO also allows organizations to visualize the true economic impact of their capital investments.

Components of TCO for Bridge Cranes

Initial Purchase Price

The first component of TCO is often the most straightforward—the initial purchase price of the bridge crane. This price will vary based on several factors:

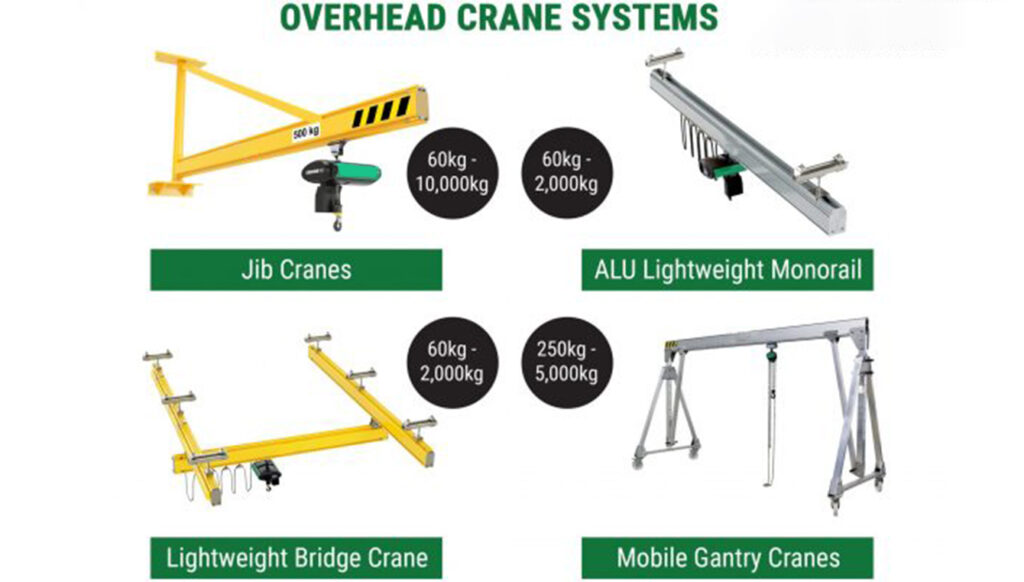

- Type of Crane: Single-girder and double-girder cranes, which offer different lifting capabilities and functionalities.

- Load Capacity: Higher load capacities generally incur higher costs.

- Customization Features: Any necessary modifications or additional features will inflate the base price.

Case Study: Price Comparison

For instance, a chassis manufacturer might purchase a basic single-girder crane for 50,000,whileaconstructionfirmmayspend50,000, while a construction firm may spend 50,000,whileaconstructionfirmmayspend150,000 on a more robust double-girder crane. Although the upfront cost seems manageable, it can lead to hidden costs down the line if the chosen crane cannot meet lifting demands.

Installation Costs

Once equipped with a bridge crane, installation costs become relevant. These costs may include:

- Structural Reinforcements: Modifications to the building’s infrastructure to support the crane safely may lead to higher initial spending.

- Expert Installation Teams: Employing skilled labor ensures the crane is installed correctly but can increase upfront expenses.

Successful Installation Example

Consider a logistics company that invested significantly in both structural modifications and professional installation services. They reported minimizing future maintenance costs because of a thorough installation, thereby validating the initial investment.

Operational Costs

Daily Operational Expenses

Operational costs encompass the expenses incurred during the everyday use of the bridge crane, including:

- Energy Costs: Electric cranes will contribute to ongoing electricity expenses.

- Labor Costs: Wages paid to operators who handle the crane.

- Regular Inspections: Compliance-based inspections are necessary to maintain safety standards.

Case Study: Energy Efficiency

A manufacturing plant that upgraded to an energy-efficient bridge crane reported a 20% reduction in energy bills. This savings added a significant advantage to their operational budget, highlighting the value of investing in modern technology.

Frequency of Use

The efficiency of a bridge crane also depends on its frequency of use. If a crane is used frequently, the operational costs will increase proportionally.

Maintenance Costs

Routine Maintenance

Routine maintenance is integral to extending the lifespan of a bridge crane. Regularly scheduled maintenance intervals help identify potential issues before they escalate into major repairs.

Potential Repair Costs

While some maintenance is predictable, repairs can be unpredictable and costly. Owners must budget for the following:

- Parts Replacement: Wear and tear can lead to significant expenses if critical components fail.

- Emergency Repairs: Sudden breakdowns can incur substantial costs not accounted for in budgets.

Example of Maintenance Planning

A steel processing plant adopted a proactive maintenance approach, resulting in their crane experiencing far fewer operational disruptions—leading to savings that surpassed maintenance costs by 30%.

Training Costs

Importance of Operator Training

To operate a bridge crane safely and efficiently, organizations need to invest in proper training for their operators. This training ensures compliance with safety regulations and avoids accidents that can be costly and hazardous.

Benefits of Training

The right training programs can lead to:

- Reduced Risk of Accidents: Certified operators are less prone to errors.

- Increased Productivity: Knowledgeable staff can optimize crane use, shortening job completion times.

Successful Training Implementation

A manufacturing company that implemented an extensive operator training program reported a significant drop in accidents and a corresponding increase in productivity, justifying their investment in training initiatives.

Downtime Costs

Understanding Downtime Impact

Downtime specifically refers to periods when a bridge crane is not operational. This greatly affects productivity and revenue generation.

Calculating Downtime Expenses

When estimating the costs incurred during downtime, consider:

- Daily Revenue Loss: Calculate the average revenue lost during each day the crane isn’t functional.

- Fixed Operational Costs: Many expenses, such as facility rent and wages, continue even when operations are halted.

Real-World Downtime Example

A shipping company facing unplanned downtime due to a crane malfunction lost approximately $1,000 daily. By investing in a more reliable crane model, they reduced their downtime by 75%, showcasing the importance of reliable machinery in overall TCO calculations.

End-of-Life Costs

What Happens When the Crane is No Longer Needed?

When a bridge crane reaches the end of its usable service life, organizations must consider the associated costs of disposal or resale.

Minimizing End-of-Life Expenses

Planning for end-of-life costs involves considering:

- Resale Value: Maintaining a crane in excellent condition can substantially boost its resale value.

- Disposal Costs: Efficiently handling crane disposal can prevent unnecessary expenditures.

End-of-Life Strategy Example

A construction firm that maintained its crane well was able to reclaim over 50% of its initial investment by reselling it—a significant saving that positively affected their overall TCO mindset.

Call to Action

If you’re contemplating the purchase of a bridge crane, reach out today for tailored guidance to optimize your decision. Understanding the complete TCO insights will empower your organization to make economically sound choices that enhance efficiency and profitability.

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice