5 Reasons to Choose a European Wire Rope Hoist

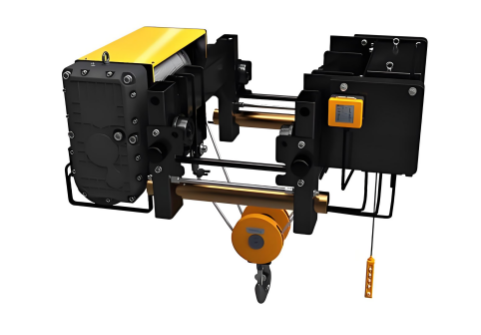

The European wire rope hoist has become one of the most popular lifting solutions in recent years. Known for compact design, advanced safety features, and long service life, it is widely used in manufacturing, logistics, construction, and heavy industry. Below are the top reasons why global buyers prefer this modern type of electric wire rope hoist.

1. Low Headroom Design for Maximum Space Utilization

Unlike traditional hoists, the European type wire rope hoist integrates motor, gearbox, drum, and limit switch into a compact housing. This reduces installation dimensions by up to 30%, making it ideal for facilities with limited headroom. The optimized design expands the effective working area and allows smoother operations in workshops, warehouses, and production lines.

2. Ultra-Quiet Operation

Noise reduction is a key advantage.

Equipped with hardened gear reducers and sealed bearings to minimize vibration.

Variable frequency drive (VFD) technology prevents noise during start and stop.

Operating noise is ≤65 dB, much lower than conventional models.

This makes the wire rope hoist perfect for precision workshops, logistics centers, and indoor warehouses where a quiet environment is essential.

3. Modular Design for Easy Maintenance

The hoist adopts modular engineering:

Core parts such as motors, gearboxes, and electrical modules can be replaced independently.

High interchangeability reduces spare part inventory.

Maintenance downtime is significantly reduced, lowering long-term costs.

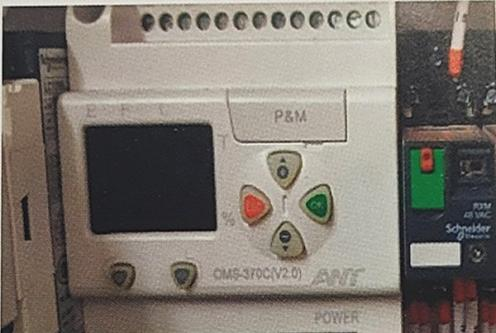

4. Advanced Electrical Control System

Modern European hoists combine precision and reliability:

VFD control enables smooth lifting and travel, reducing load swing.

Overload limiter automatically stops the hoist in case of excess load.

Height limit protection ensures safe rope winding and prevents damage to the drum.

These features provide higher safety and stability compared with traditional hoists.

5. High-Quality Core Components

Each component is designed for durability and safety:

| Component | Material | Advantages |

|---|---|---|

| Wheel | High-strength alloy steel | Wear-resistant, impact-proof |

| Pulley & Rope Guide | High-strength nylon | Reduces rope wear and lowers noise |

| Wire Rope | Steel-core, anti-rotation | High tensile strength, ≥4x safety factor |

Typical Applications

The European wire rope hoist is widely applied in:

Warehousing & logistics – safe heavy load handling, 24/7 continuous duty.

Automobile manufacturing – accurate positioning for flexible production lines.

Metallurgy & energy – sealed design for high-temperature and dusty environments.

Construction sites – weather-resistant, modular design for outdoor lifting.

Clean workshops & pharmaceuticals – ultra-low noise, zero contamination.

Hoist Comparison: European vs Chain vs Traditional

| Feature / Type | European Wire Rope Hoist | Chain Hoist | Traditional Wire Rope Hoist |

|---|---|---|---|

| Design | Compact, low headroom, modular | Simple, lightweight | Bulkier, larger space needed |

| Capacity | 2t – 32t (heavy duty) | 0.5t – 10t (light to medium) | 1t – 50t (medium to heavy) |

| Precision | VFD control, smooth lifting | Single speed, limited precision | Dual speed, less stable |

| Noise Level | ≤65 dB, ultra-quiet | Low to medium | Higher noise & vibration |

| Maintenance | Modular, easy replacement | Minimal, chain wear common | Higher cost, non-modular |

| Service Life | 10–15 years (FEM M5–M6) | 5–8 years | 8–12 years |

| Safety Features | Overload & height limiter, soft start/stop | Basic overload | Mechanical limiters only |

| Application | Factories, warehouses, metallurgy, cleanrooms | Small workshops, garages | Steel plants, heavy-duty sites |

| Cost Range | Mid-to-high ($3,500 – $70,000) | Low ($300 – $5,000) | Medium ($2,000 – $40,000) |

Technical Parameters

Lifting capacity: 2t – 32t

Lifting height: 6m – 24m

Speed: single speed / dual speed / VFD adjustable

Duty class: FEM M4 – M6

Voltage: 380V / 400V / 415V (customizable)

Price Range

The cost of a European wire rope hoist varies by tonnage, configuration, and brand:

Entry-level (2–5t): $3,500 – $7,500

Standard type (5–10t): $7,500 – $22,000

Heavy-duty custom (10t+): $20,000 – $70,000

Buying Tips

When selecting a wire rope hoist, consider:

Maximum lifting load (recommend 120% of daily max load).

Working frequency (daily cycles determine duty class).

Space restrictions (low-headroom type requires special rail check).

Special conditions (explosion-proof, anti-corrosion, outdoor use).

Conclusion

The European wire rope hoist offers a perfect balance of compact design, silent operation, advanced control, and long service life. Whether you are upgrading a factory, expanding a warehouse, or building new facilities, this modern hoist provides maximum efficiency and safety.

👉 Contact SLKJCrane today for a free consultation and quotation.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen Hu

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

Certifications and Standards

Our European type wire rope hoist complies with FEM, DIN, ISO standards and comes with CE / SGS / TUV certification, ensuring safety and quality.

FAQ

Always lift vertically, avoid diagonal pulling.

Regularly check rope guides and limit switches.

Ensure rope winds smoothly into the drum.

Wire rope wear, hook deformation, limit switch sensitivity, and pendant control.

Yes, hoists must be operated by trained personnel only. Never press opposite direction buttons at the same time.

FEM classifications (e.g., M4, M5) define usage cycles and lifespan. For heavy production environments, choose a higher classification like M5.

Perform weekly inspections, lubricate parts regularly, avoid overloading, test brakes monthly, and ensure operators are trained and certified.

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios When people ask me about spider

How To Choose The Right Spider Crane

How To Choose The Right Spider Crane (Mini Crawler Crane) for a Project – My Practical Experience When

Low Headroom Wire Rope Hoist for Tight Workshops | SLKJCrane

Cost Saving Low Headroom Wire Rope Hoist for Tight Workshops When I visit customers’ workshops and warehouses, I

Spider Crane Guide 2025 | Types, Specs & Applications – SLKJCrane

Spider Crane Guide 2025: Types, Specs, Applications & Buying Tips In the last decade, spider cranes (mini spider

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice