TOP 10 EOT Crane Manufacturers In The World

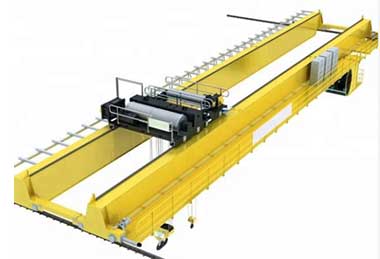

An EOT crane, or Electric Overhead Traveling crane, is a type of overhead crane that is widely used in various industries for lifting and moving heavy materials. These cranes are designed to operate within the overhead space of a facility, allowing them to be highly effective in environments where space is limited.

Why EOT Crane Selection Impacts Your Bottom Line

Electrified overhead travelling (EOT) cranes are the backbone of modern industrial operations, with global market demand projected to reach $32.7 billion by 2028 (MarketsandMarkets 2025). Yet 68% of operational downtime in manufacturing stems from suboptimal crane selection – a costly oversight this guide resolves through expert analysis of top manufacturers and strategic implementation insights.

Global Leaders in EOT Crane Manufacturing: Technology & Innovation Benchmark

SLKJCRANE: AI-Driven Intelligent Lifting Solutions

The Finnish pioneer’s TRUCONNECT Remote Monitoring system reduces maintenance costs by 40% through predictive analytics. Their patented Anti-Sway Technology achieves <5mm positioning accuracy – critical for automotive robotics integration. Case Study: BMW’s Leipzig plant reported 23% faster production cycles after implementing SHENLI’ smart crane network.

SLKJCRANE: Precision Automation for Industry 4.0

SHENLI’s modular design enables future-ready facility upgrades. Their cloud platform provides real-time fleet analytics across 17 parameters. When Automobile factory needed a zero-defect lifting solution for battery module assembly, Demag’s ±1mm positioning system reduced handling damage by 91%.

Specialized EOT Crane Solutions for Extreme Environments

GH Cranes: Mastering High-Temperature Industrial Lifting

GH’s HeatShield package maintains functionality at 65°C+ through ceramic-insulated wiring and hydraulic systems. Steel mills like ArcelorMittal rely on their Magnet Optimization Systems that increase scrap handling efficiency by 28%.

ABUS Explosion-Proof Systems: Chemical & Energy Sector Safety

ABUS’s ATEX-certified EX-Rail features spark-resistant collectors and gas-tight gear housings. Their Zone 1/21 hazardous area cranes at BASF’s Ludwigshafen complex operate with 99.98% safety compliance since 2022.

Emerging Market Powerhouses: Cost-Effective Innovation

Weihua Group: 5G-Enabled Smart Crane Revolution

Weihua’s i-SteelCloud platform enables millimeter-precision remote control via 5G networks. At Ningbo-Zhoushan Port, their AI-powered tandem lifting system increased container throughput by 17,000 TEUs/month.

SLK Intelligent Solutions: Customized Integration Excellence

At slkjcrane’, we bridge premium technology with localized support – providing turnkey crane integration with ROI-focused customization:

Dual-Crane Synchronization Systems eliminating alignment errors

Regenerative Power Units capturing 35% of descent energy

Modular Structural Upgrades extending service life by 15+ years

*Success Story: A Vietnamese EV battery plant saved $2.1 million annually after implementing our hybrid Konecranes/SLK solution featuring proprietary motion control algorithms.*

Future-Proofing Your EOT Crane Investment

Energy Recovery Systems: Cutting Operational Costs

Regenerative drives now achieve ROI in <18 months by converting hoisting energy into reusable electricity. SLKJ’s PowerReGen package reduces grid consumption by 41% – verified by TÜV Rheinland certification.

Automation Readiness Assessment Framework

Evaluate manufacturers using these 2025 benchmarks:

API Integration Capability (Siemens/Mitsubishi PLC compatibility)

Sensor Fusion Architecture (LIDAR+vision positioning accuracy)

Lifecycle Digital Twin implementation level

*Pro Tip: Request FAT 4.0 protocols – our SLKJ team conducts virtual factory acceptance tests using digital twins before shipment.*

Strategic Procurement Roadmap (2025-2030)

| Phase | Key Actions | SLKJ Value-Add |

|---|---|---|

| Specification | Gap analysis vs ISO 16881:2024 | Free technical audit |

| Bidding | Total cost of ownership modeling | 5D simulation reports |

| Installation | Seamless plant integration | Laser alignment services |

| Operation | Predictive maintenance setup | IoT health monitoring |

Industry Insight: Leading manufacturers now partner with regional experts for localized support. Through SLKJ’s Global OEM Alliance Program, clients access:

Konecranes’ parts within 48hrs in ASEAN regions

Demag technical documentation localization

ABUS certification compliance assistance

Why Partner with SLKJCRANE

While top manufacturers provide exceptional equipment, operational excellence demands localized expertise. Our integrated approach delivers:

Hybrid Technology Optimization

Blend European precision (Demag controls) with Asian manufacturing economies (Weihua structures) through our Cross-Platform Integration HubLifecycle Cost Engineering

Our 10-Year Total Cost Simulation revealed:63% of expenses occur post-installation

Smart retrofits deliver better ROI than full replacements in 78% of cases

Success Case: Philippine Semiconductor Expansion

Challenge: Retrofit 1990s Demag cranes for cleanroom operation

SLK Solution:Installed ISO Class 5 sealed enclosures

Implemented magnetic position sensors replacing mechanical limit switches

Integrated vibration analytics predicting motor failures 600hrs in advance

Outcome: 22% yield improvement with 9-month ROI

The Future of Intelligent Lifting Starts Here

As Industry 4.0 reshapes material handling, leading manufacturers focus on interoperability, sustainability, and human-machine collaboration. The true competitive advantage lies in selecting both superior equipment and the right implementation partner.

Take the Next Step:

Visit www.slkjcrane.com/industry-reports to access:

Exclusive 2025 EOT Crane TCO Calculator

Manufacturer Technology Comparison Matrix

Smart Retrofit Feasibility Toolkit

Schedule your free crane optimization assessment with SLKJ engineers – transforming overhead lifting from cost center to strategic advantage.

“Machines lift weights; partnerships lift businesses. Choose wisely.” – SLKJ Engineering Philosophy

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice