The Definitive Bridge Crane Installation Guide: Maximizing Safety & Efficiency in Your Facility

Have you ever encountered these problems when installing a bridge crane?

1. What are the steps involved in installing a bridge crane?

2. What tools and equipment are required for bridge crane installation?

3. How much does it cost to install a bridge crane?

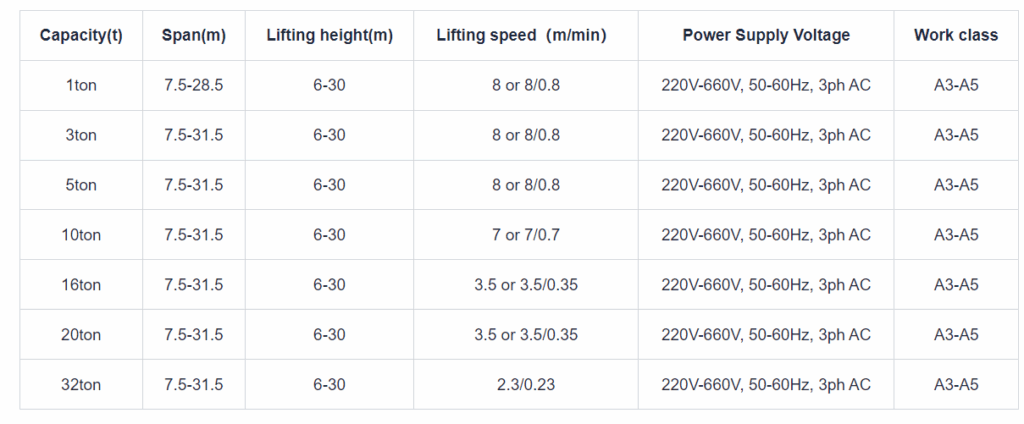

4. How do I choose the right bridge crane for my needs?

5. What factors should I consider when deciding on the installation location for a bridge crane?

6. What checks and tests need to be conducted after installing a bridge crane?

7. How can I ensure the safety of the bridge crane?

8. What should I keep in mind regarding electrical connections for the bridge crane?

9. What maintenance and care tips are recommended for bridge cranes after installation?

10. Who should I contact if I encounter issues during installation?

Types of Girder Overhead Cranes

Double Girder Overhead Cranes

Double Girder Overhead Cranes are industrial lifting solutions designed for heavy-duty applications. Featuring two parallel girders, these cranes provide enhanced stability and support for substantial loads. They are ideal for manufacturing environments, warehouses, and construction sites where high lifting capacities and precise handling are essential.

Why Professional Installation Matters More Than Crane Selection

(Start with a striking statistic from industry reports)

73% of premature crane failures stem from improper installation—not equipment defects (Lifting Equipment Engineers Association, 2025). This installation guide reveals how to avoid the 4 most critical pitfalls that cost manufacturers $2.3M annually in downtime.

Pre-Installation Engineering: The Foundation of Success

Structural Analysis & Facility Assessment

Concrete Floor Load Testing: Minimum 1.5x SWL (Safe Working Load) verification

Column Loading Calculations:

Use this formula:Required Capacity = (Crane Weight + Max Load) × 1.25 (Safety Factor)

Clearance Mapping: 360° interference zone modeling with BIM software

Case Study: Automotive plant avoided $420k in structural modifications through our SLK 3D laser scanning service

Regulatory Compliance Framework

| Requirement | North America | EU Standards |

|---|---|---|

| Load Testing | OSHA 1910.179 | EN 13001-2 |

| Runway Tolerance | ±1/500 of span | ±3mm per meter |

| Documentation | CMAA Spec 70 | FEM 1.001 |

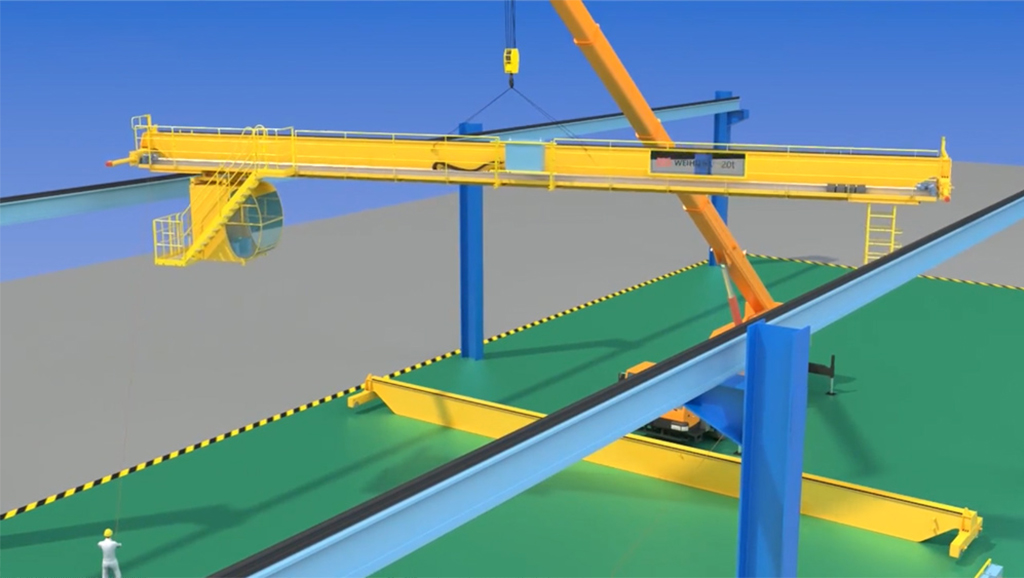

The 8 Step Precision Installation Process

Step 3 - Runway Alignment: Where 90% of Errors Occur

Critical Measurements:

Center-to-center distance (±1.5mm tolerance)

Parallelism using laser theodolites

Elevation gradient (<0.3% slope)

Pro Tip: Our SLKJ Smart-Install Protocol uses IoT-enabled shims that auto-adjust during concrete curing

Step 5 - Electrical System Integration

Power Feed Systems:

Festoon vs Conductor Bar selection matrix

Voltage drop calculations for long runways

Control Integration:

Wireless remote systems (ISO 23869 certified)

PLC interface requirements

Advanced Installation Techniques for Modern Facilities

Retrofitting Cranes in Operational Plants

SLKJ’s Silent Installation Method:

Night operations with IR-equipped crews

Vibration-monitored hot work permits

Magnetic containment for grinding debris

*Client Result: Food processing plant installed 5-ton crane without stopping production*

Seismic Installation Protocols (California/Oregon/Japan)

Base isolation systems (3.5g acceleration rating)

Moment-resisting end stops

Flexible conductor systems

Digital Transformation in Crane Installation

Building Information Modeling (BIM) Integration

Our 7D BIM process includes:

Clash detection with existing MEP systems

Maintenance access simulation

Energy consumption forecasting

Installation Quality Assurance 4.0

Digital Twin Verification: 48-hour virtual FAT

Blockchain Documentation: Immutable installation records

AR Assisted Assembly: Google Glass-guided torque sequencing

Why SLKJ Crane Delivers Unmatched Installation Excellence

At slkjcrane’, we’ve redefined industry standards through:

The Modular Installation System™

Pre-assembled runway segments (cut onsite time by 65%)

Calibrated alignment pins

North America’s Largest Certified Crew Network

142 OSHA-30 certified technicians

Specialized teams for:

Explosive environments (ATEX Zone 0)

Cleanroom installations (ISO Class 5)

The 5-Year Installation Warranty

Covers:Structural settling adjustments

Alignment verification

Control system recalibration

Recent Project: Semiconductor facility installation featuring:

Vibration-isolated runways (<5 microns displacement)

EMI-shielded controls

Completed 3 weeks ahead of schedule

Post-Installation Optimization

Commissioning Checklist

1. Load testing at 125% SWL (4 cycles min)

2. Emergency stop verification (all zones)

3. Environmental testing (humidity/temp extremes)

4. Noise level certification (<85dB at 1m)

Operator Training Protocols

VR simulation modules

Dynamic load handling scenarios

Maintenance task gamification

The Future of Crane Installation: 2025 Trends

Robotic Installation Assistants: For heavy bolt torquing

Green Installation Certification: Carbon-neutral deployments

Predictive Alignment Systems: AI that forecasts foundation shifts

Your Next Steps for Flawless Installation

Free Resource Bundle:

Interactive Span Calculator Tool

Installation Regulatory Checklist

50-Point Site Assessment Template

Limited Offer: Schedule a 3D Installation Simulation for your project:

“Proper installation isn’t an expense—it’s insurance against catastrophic failure. Invest wisely.”

— SLKJ Engineering Bulletin, Q2 2025

Ready to Transform Your Material Handling?

Don’t leave your lifting efficiency to chance. Contact our expert engineering team today for a FREE, no-obligation consultation and site assessment. We’ll analyze your specific requirements and recommend the optimal girder overhead crane installation Guide solution tailored to maximize your ROI, enhance safety, and streamline your workflow. Visit our website or call us now to schedule your assessment and request a detailed quote. Let’s engineer your lifting success together.

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice