A Beginner’s Guide to Overhead Cranes From Overhead Crane Manufacturer

In an era where industrial efficiency is paramount, choosing the right overhead crane can make or break your operational productivity. Are you finding it difficult to select the perfect crane for your unique requirements? This Overhead Crane Guide aims to illuminate the complexities of overhead crane selection and operation, addressing common client concerns and offering effective solutions to elevate your material handling processes.

Overview of Overhead Cranes

Overhead cranes, also known as bridge cranes or industrial cranes, are vital material handling machines that enable the horizontal lifting, lowering, and transportation of loads. Typically, an overhead crane consists of a hook and line mechanism that moves along a horizontal beam, which in turn operates on runway beams supported by the building structure. Designed for heavy-duty applications, overhead cranes have a high lifting capacity and are primarily used for transporting loads within manufacturing facilities, warehouses, shipping ports, and other industrial environments.

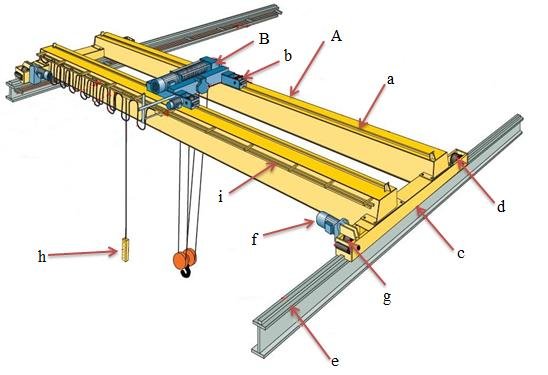

Components of an Overhead Crane

An overhead crane generally consists of three main parts:

- Crane Bridge: The horizontal structure that spans the runway.

- Hoist or Trolley: The lifting mechanism that moves across the crane bridge and raises loads vertically.

- Runway: The tracks that connect to the building’s structural framework.

Key Terms in Crane Operation

- Crane Capacity: The maximum weight that the crane is rated to lift.

- Crane Span: The horizontal distance between the runways the crane operates on.

- Lift or Hook Height: The vertical measurement from the ground to the crane hook, impacting the runway’s clearance.

- Bridge, Trolley, and Lift Speed: The operational speed of the bridge or trolley, and the hoist lift speed. Dual-speed options are available.

Crane Configuration

Overhead cranes primarily come in two structural configurations: Top Running and Under Running.

Top Running Overhead Cranes

Top running cranes have a bridge that moves on top of the runways, which are supported by columns or specifically designed structural members. This configuration is the most common and allows for the load to be transferred directly to the supporting columns or independent structures, maximizing the available lift height.

Categories of Top Running Cranes:

Single Girder Crane: Comprising two end trucks, a hoisting mechanism, and a single bridge girder. It is cost-effective, making it ideal for applications with lower wheel loads.

Double Girder Crane: Consisting of two end trucks and two bridge girders, providing better hook height and load handling.

Box Girder Crane: Built with a closed tubular main girder for extreme durability, suitable for heavy-duty material handling.

Under Running Overhead Cranes

Under running cranes feature end trucks that hang from the underside of the runway, eliminating the need for additional ground supports. This design saves floor space and can be more cost effective.

Applications for Overhead Cranes

Overhead cranes find utility across various industries, including automotive, food and beverage, chemicals, commercial printing, manufacturing, paper, steel, and logistics.

- Assembly: Moving products during manufacturing processes.

- Transport: Loading finished products onto trucks and other vehicles.

- Storage: Handling heavy items in and out of storage areas.

- Warehouse Operations: Relocating goods in and out of shipping docks.

Advantages of Using Overhead Cranes

Overhead cranes are renowned for their numerous advantages:

- Versatility: Capable of operating on any factory floor and adaptable to changing needs.

- Customizability: Tailored solutions with various attachments for different load types.

- Operator Comfort: Designed with ergonomics in mind to enhance efficiency and safety.

- Efficiency: Move loads efficiently without reverse movement in aisles.

- Load Control Options: Choose from radio remote controls, pendant controls, or cabin operation.

- Lower Maintenance Costs: Advanced technology reduces maintenance needs compared to traditional lifting equipment.

- Precision Placement: Accurately place loads in desired locations with high precision.

- Reduced Labor Costs: A single overhead crane can often replace multiple forklifts, covering larger areas.

- Safety Features: Various safety measures ensure the safety of operators and loads.

- Increased Lifting Height: Provides higher lifting capabilities, improving operational efficiency.

Choosing the Right Overhead Crane

Selecting the correct overhead crane is crucial, as it depends on various factors:

- Load Capacity: The maximum load should not exceed the crane’s rated capacity.

- Crane Span: The width required for the crane’s operation influences its size.

- Operational Frequency: Understand how often the crane will be used to define its classification.

- Support Structure: Overhead cranes can be supported either from building columns or by dedicated runway structures.

Types of Overhead Cranes

Single Girder Overhead Cranes

Single Girder Overhead Cranes are the perfect solution for maximizing vertical space and enhancing operational efficiency in various industrial settings. These cranes feature a robust yet lightweight design, offering significant lifting capacities while ensuring smooth and controlled movement of loads.

Low Headroom Girder Overhead Crane

Low Headroom Overhead Cranes are specially designed to maximize vertical space in facilities with limited headroom. These cranes are ideal for warehouses and manufacturing plants where every inch of height counts, providing a practical solution for lifting and moving heavy loads efficiently.

Underslung Girder Overhead Crane

Underslung Cranes are a versatile and efficient solution for overhead lifting in constrained spaces, providing optimal headroom and maximizing usable area within your facility. These cranes are ideal for operations with low ceilings, enabling seamless material handling without sacrificing safety or performance.

FEM/DIN Girder Overhead Crane

FEM Standard Overhead Cranes are designed to meet the highest quality and safety standards for material handling in various industrial applications. Built according to the FEM (Fédération Européenne de la Manutention) guidelines, these cranes ensure durability and performance in demanding environments, making them the ideal solution for manufacturing plants, warehouses, and distribution centers.

Offset Trolley (LDP) Girder Overhead Crane

LDP Overhead Crane is a high efficiency lifting solution designed for various industrial applications. Characterized by its unique low headroom design, the LDP crane maximizes available vertical space, making it an ideal choice for facilities with limited overhead clearance. This type of crane is particularly suited for lifting heavy loads in manufacturing plants, workshops, and warehouses, where safety and precision are paramount.

Magnetic Overhead crane

Magnetic Overhead Cranes are engineered for efficient and effective material handling, particularly when working with ferrous materials. These specialized cranes utilize powerful electromagnets or permanent magnets to securely lift and transport steel plates, coils, and other magnetic loads with ease and precision.

Considerations for Selecting a Top Running Double Girder Crane

To make an informed decision, assess:

- Crane lifting capacity

- Crane lift height

- Required runway height

- Building width and height

- Crane span

- Track size and length

- Hoist approach and end approach

- Lifting speed

- Bridge travel speed

- Trolley travel speed

- Electrical requirements

- Control preferences

Selecting the right overhead crane is paramount for optimizing material handling efficiency in any industrial setting. With this Overhead Crane Guide, you are equipped with the necessary knowledge to make informed decisions. Remember that SLKJ Crane is here to support you with specialized services and expertise, ensuring that your lifting operations are safe, efficient, and aligned with your business objectives. Don’t hesitate to reach out for a consultation today and take the first step towards transforming your material handling processes!

By investing time in understanding and choosing the right overhead crane, you are setting the groundwork for enhanced productivity, safety, and ultimately, greater success in your industrial endeavors.

Maintenance of Overhead Cranes

Given the complexity of overhead cranes, regular maintenance is essential for their longevity and performance. Here are recommended maintenance checks:

- Brake System Checks: Inspect nuts, pins, and positioning plates for completeness and integrity.

- Cable and Pulley Inspections: Ensure proper conditions with no fraying, skipping, or tangling.

- Safety Device Testing: Validate the functionality of limit switches and emergency stops.

- Lubrication: Ensure all moving parts are adequately lubricated.

- Alignment Checks: Confirm that tracks have no obstructions that could impede crane operation.

- Noise Checks: Listen for unusual sounds that may indicate mechanical issues.

Conclusion

When you partner with SLKJ Crane, you gain access to a supplier that prioritizes quality, safety, and customer satisfaction. Here are some advantages:

Expertise

Our team consists of experts who understand the complexities of material handling and can offer strategic advice tailored to your industry.

Custom Solutions

Every operation is unique. We provide customizable overhead cranes that can meet any specifications according to your workflow needs.

Competitive Pricing

We offer competitive pricing without compromising quality, ensuring you get the best value for your investment.

Commitment to Safety

Safety is our top priority. All our cranes adhere to international safety standards, ensuring a safe working environment.

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice