Suspended Bridge Cranes: Technical Specifications and Industrial Applications

1. Definition and Structural Classification

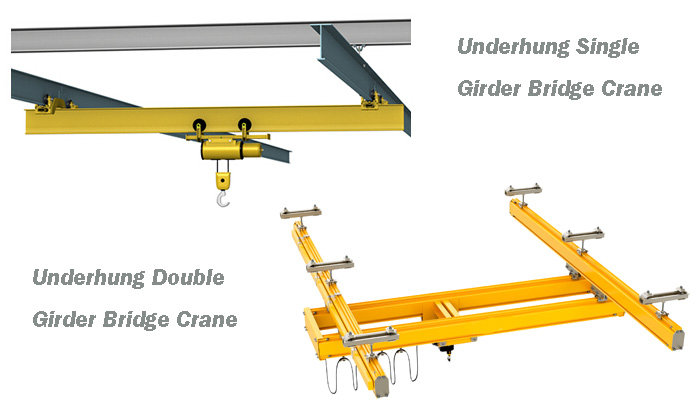

Suspended bridge cranes are overhead material handling systems mounted on elevated runways rather than floor-supported columns. These cranes fall into two primary categories:

-

Single-Girder Type

- Max capacity: 0.5–10 tons

- Span range: 3–30 m

- Operating speed: 4–30 m/min

-

Double-Girder Type

- Max capacity: 0.5–20 tons

- Span range: 7.5–31.5 m

- Work classification: A3–A6 (ISO standard)

Unlike conventional bridge cranes that require dedicated support columns, suspended variants utilize existing roof structures with reinforced bearing capacity ≥125% of rated load

2. Key Technical Advantages

2.1 Space Optimization

- Requires zero floor space for support structures

- Vertical clearance efficiency: 85–92%

- Adaptable to irregular layouts via modular track systems

2.2 Performance Metrics

| Parameter | Single-Girder | Double-Girder |

|---|---|---|

| Positioning Accuracy | ±5 cm | ±2 cm |

| Duty Cycle | 60% ED | 80% ED |

| Noise Level | ≤75 dB(A) | ≤68 dB(A) |

| Energy Consumption | 3–7.5 kW | 5–15 kW |

| ED: Equipment Duty (ISO 4301-1:2016 standard) |

3. Core System Components

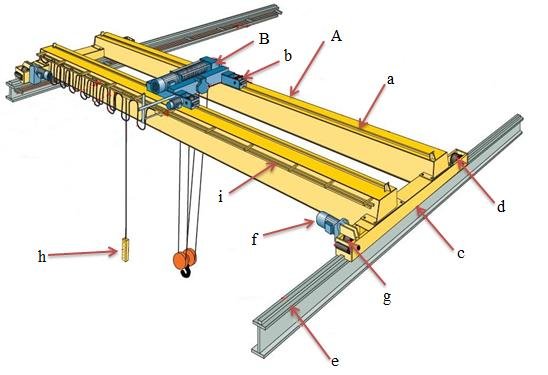

-

Load-Bearing Structure

- Galvanized steel tracks (S355JR grade)

- Adjustable suspension kits (M20–M36 bolts)

- Anti-sway trolley systems

-

Drive Mechanisms

- 3-phase asynchronous motors (IE3 efficiency class)

- Frequency converters for speed control (0.1–100% VFD)

- Fail-safe electromagnetic brakes

-

Control Systems

- IP65-rated pendant controllers

- 2.4 GHz wireless remote options

- Collision avoidance sensors (5–30 m range)

4. Industrial Applications

4.1 Manufacturing

-

Automotive Assembly

- Engine hoisting (typical load: 1.2–3.5 tons)

- Precision placement tolerance: ±1 mm

-

Electronics Production

- Cleanroom-compatible models (ISO Class 5–8)

- ESD-protected lifting attachments

4.2 Logistics Operations

-

High-Bay Warehousing

- 24/7 automated operation capability

- Inventory turnover improvement: 35–40%

-

Cross-Docking Facilities

- Simultaneous handling of 2–4 containers

- Cycle time reduction: 22–28 minutes/load

5. Safety and Compliance

5.1 Mandatory Standards

- Structural Welding: EN 1090-2 EXC3 certification

- Electrical Systems: IEC 60204-32 compliance

- Load Testing: 125% static + 110% dynamic tests

5.2 Maintenance Protocol

-

Daily Checks

- Track alignment deviation ≤1.5‰

- Wire rope wear limit <10% diameter loss

-

Annual Overhaul

- Bearing replacement threshold: 50,000 cycles

- Structural deformation tolerance: ≤L/800

6. Cost Analysis (2025 Market Data)

| Configuration | Initial Cost (USD) | Lifetime (Years) | ROI Period |

|---|---|---|---|

| Basic Manual | 8,200–12,500 | 8–10 | 16 mo |

| Automated | 25,000–45,000 | 12–15 | 28 mo |

| Customized | 50,000+ | 15–20 | 36 mo |

ROI calculations based on 70% utilization rate

7. Emerging Technical Trends

-

-

Smart Monitoring

- IoT-enabled predictive maintenance (98% fault detection accuracy)

- Cloud-based usage analytics

-

Hybrid Power Systems

- Regenerative braking energy recovery (12–15%)

- Solar-assisted operation

-

Advanced Materials

- Carbon fiber reinforced tracks (40% weight reduction)

- Self-lubricating polymer wheels

-

This technical profile integrates verified specifications from leading manufacturers and global engineering standards. For customized configurations, consult certified suppliers to ensure compliance with local regulations and operational requirements

All News

Recent Posts

2025/1/25

2025/2/7

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice