Spider Crane Guide 2025: Types, Specs, Applications & Buying Tips

In the last decade, spider cranes (mini spider cranes) have moved from a niche machine to a must-have lifting solution on many complex jobsites. Whenever project teams face tight access, indoor lifting, fragile loads or strict noise/emission limits, a compact spider crane often becomes the most efficient option.

This guide gives you a practical, engineering-oriented overview of spider cranes — what they are, how they work, where they shine, and how to choose the right model when you want to buy a spider crane from a professional manufacturer rather than just rent one locally.

1. What Is a Spider Crane?

A spider crane (also called mini spider crane or mini crawler crane) is a small, crawler-type crane with four or more outriggers that unfold like a spider’s legs. It combines:

A telescopic or knuckle boom

A compact crawler undercarriage

Foldable outriggers for stability

Either electric, diesel or hybrid power

Precise control, often by remote control

Key characteristics:

Very compact in transport mode – can pass through standard doorways, elevators, narrow corridors

Large working envelope vs. footprint – once outriggers are deployed, it offers strong lifting capacity in a small area

Flexible power options – pure electric, battery or low-emission diesel for different jobsite requirements

Unlike big truck cranes or tower cranes, spider cranes are designed for access-critical, space-limited and sensitive environments such as:

Shopping malls and airports

High-rise residential projects

Glass and curtain wall installation

Factories and industrial plants

Rooftops and inner courtyards

2. Core Features & Advantages of Spider Cranes

From an engineering and ROI perspective, spider cranes offer several clear advantages.

2.1 Compact size & narrow access

Can enter through standard doors or even industrial elevators

Fits between existing structures, inside atriums, courtyards or backyard extensions. In fact, the spider crane is often considered the magic tool for confined space operations where truck cranes cannot set up.

Works in tight alleys, inner city streets and congested jobsites where truck cranes cannot set up

2.2 Flexible outriggers for stable lifting

Multi-position outriggers allow the crane to adapt to irregular spaces

Each outrigger can often be extended to different lengths and angles

Built-in load charts and interlocks ensure safe working within the stability limits

2.3 Precise lifting & remote control

Proportional control or full remote control enables millimetre-level positioning

Ideal for glass, curtain wall, machinery installation, HVAC units, artwork and other fragile loads

Allows the operator to stand at the best viewing angle while lifting, improving safety

2.4 Multiple power options

Depending on the model and configuration, spider cranes can be equipped with:

Electric motors (AC power from jobsite or battery packs) – zero local emissions, low noise

Diesel engines – for outdoor or semi-outdoor projects with longer duty cycles

Hybrid systems – combining diesel with battery to adapt to mixed environments

This flexibility makes spider cranes suitable for indoor projects with strict emission regulations as well as tough outdoor conditions.

2.5 Easy transportation & setup

Compact body fits on small trucks, trailers or containers

Short setup time compared with scaffolding or complex rigging solutions

Can be repositioned multiple times in a day to serve different zones of the site

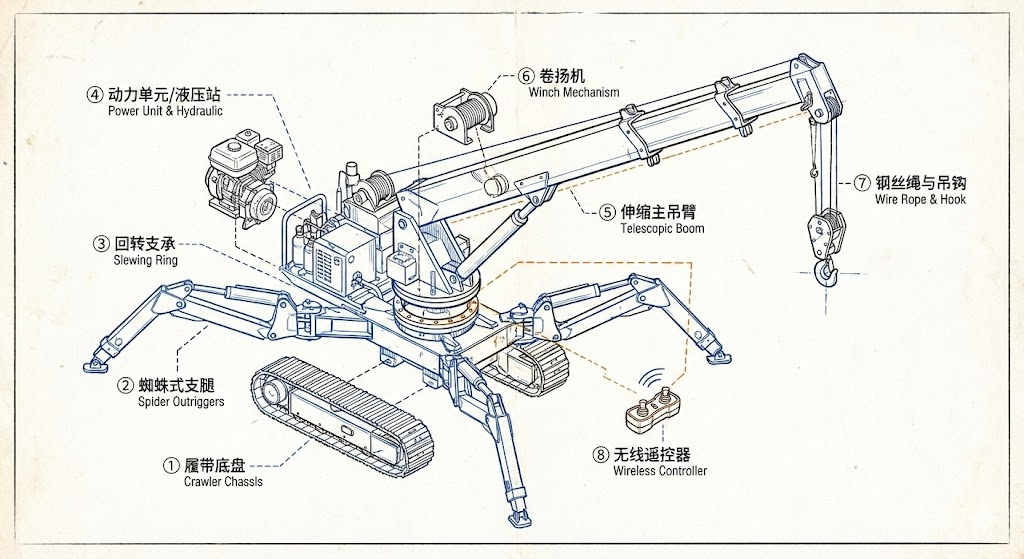

3. Main Components & Working Principle

From a technical view, a modern spider crane typically consists of the following systems:

3.1 Power system

Electric motor, diesel engine or hybrid drive

Hydraulic pumps supplying pressure to boom cylinders, winch and outriggers

Fuel tank or battery packs, plus cooling and filtration systems

3.2 Lifting system

Telescopic boom (sometimes with jib extension)

Wire rope and winch, hook block or special lifting attachments

Optional glass lifter, man basket, clamps or special hooks for different tasks

3.3 Control system

On-board control station and/or radio remote control

Proportional valves for smooth motion

Load moment indicator (LMI) and overload protection

3.4 Stability & undercarriage

Crawler tracks for manoeuvring on rough or uneven ground

Articulated outriggers with pads, sometimes with auto-levelling capability

Ground pressure is spread via pads to protect delicate floors

3.5 Safety system

Overload and anti-two-block protection

Emergency stop and safe-stop functions

Alarm and fault indication

Optional limiters for working range, height or slew angle to protect nearby structures

Working principle in brief:

The crawler undercarriage moves the crane into position. The outriggers are deployed and levelled to secure stability. The operator then controls the boom and winch (usually via remote control), following the rated load charts that consider boom length, working radius and outrigger position.

4. Typical Applications of Spider Cranes

Spider cranes are not general-purpose “big” cranes. They are specialists for complex access and delicate lifting. Typical applications include:

4.1 Glass & curtain wall installation

Lifting large glass panels and curtain wall units to façades

Working inside atriums, shopping malls and office lobbies

Combining the crane with vacuum glass lifters for safe, precise positioning

4.2 Urban housing & high-rise renovation

Rooftop lifting of HVAC units, water tanks, steel beams and equipment

Placed on parking decks, balconies or rooftops with verified load capacity

Access through narrow streets, backyards or entrances where large cranes cannot set up

4.3 Industrial plants & factory maintenance

Installation and replacement of machines, production lines, overhead pipes and tanks

Working between existing equipment with limited headroom and narrow aisles

Reducing downtime compared to dismantling large structures or using extensive scaffolding

4.4 Infrastructure & public buildings

Airports, railway stations, hospitals, museums, sports venues

Any project where noise, vibration and emissions must be controlled

Night-time or off-hour work with minimal disturbance to operations

5. Spider Crane vs Other Lifting Solutions

When planning a project, you rarely ask “Do we want a spider crane?” in isolation. The real question is:

“Is a spider crane more efficient and safer than alternatives such as truck cranes, boom lifts or scaffolding in this scenario?”

5.1 Spider crane vs truck crane

Truck crane advantages

Higher maximum capacity

Long travel distance on public roads

Spider crane advantages

Can work inside buildings and tight sites

Requires much smaller setup space

Lower ground pressure and more options for indoor/outdoor power

Conclusion: When access is narrow or indoor lifting is required, a spider crane is often the only practical solution.

5.2 Spider crane vs boom lift

Boom lift is mainly for lifting people and tools, not heavy loads

Spider crane can place heavy loads with high precision

In many glass, curtain wall or equipment installation projects, a spider crane plus workers often replaces complex combinations of boom lifts and manual handling

5.3 Spider crane vs scaffolding

Scaffolding requires long time to erect and dismantle

Spider cranes can be set up quickly, complete the lift and leave, reducing total project time

Especially suitable for one-time or low-frequency lifting tasks in finished buildings

6. Capacity & Range Overview

Spider cranes come in a wide range of capacities and boom lengths. As a simple engineering reference:

0.8–1.0 t mini spider cranes

Very compact body width (often < 800–900 mm)

Suitable for indoor lifting, glass installation, equipment up to 800–1000 kg

2–3 t spider cranes

Balance between compact size and stronger lifting

Common choice for general building and industrial use

3–5 t spider cranes

hese models offer significant power for heavier tasks. Discover more about the versatility of 3 ton and 5-ton spider cranes for handling heavier façades, rooftop equipment, and prefabricated elements

Require more attention to ground bearing capacity and outrigger setup

When planning to buy, you should always look at complete load charts (capacity vs boom radius and outrigger position) rather than just the “maximum capacity” number.

7. How to Choose the Right Spider Crane for Your Project

If you plan to purchase a spider crane instead of renting, a systematic selection approach is essential. Use the following checklist as a starting point:

7.1 Define your main application scenarios

Indoor or outdoor?

Glass and curtain wall, machinery installation, rooftop lifting, or general construction?

One primary scenario, or multiple mixed scenarios?

7.2 Required lifting capacity & radius

Maximum load weight (kg or ton)

Maximum working radius (m) at that load

Maximum lifting height (m)

These three parameters largely decide the minimum crane size you need.

7.3 Site access conditions

Minimum doorway width and height

Elevator size and capacity, if the crane needs to go to upper floors

Turning space in corridors, ramps, parking areas

Make sure the transport dimensions of the crane fit your tightest access.

7.4 Ground bearing capacity & floor structure

What is the floor load rating in kN/m² or kg/m²?

Is it a solid concrete slab, steel structure with deck, or rooftop with insulation?

Do you need outrigger mats or special load-spreading solutions?

7.5 Power supply and emission limits

Can you use AC power on site?

Are there strict emission/noise regulations (hospitals, airports, residential areas)?

Do you need pure electric / battery spider crane, or is diesel acceptable?

7.6 Utilisation rate & ROI

How many working hours per year do you expect?

Are you a specialised contractor or rental company planning to offer spider crane service to clients?

Is there potential to share the crane between several branches or projects?

By combining these answers, you and the manufacturer can quickly narrow down to 2–3 suitable models and optimise the configuration (boom length, power type, attachments, safety functions).

8. Buying a Spider Crane from a Manufacturer vs Local Rental

Even though many contractors first experience spider cranes via local rental, there are strong reasons to eventually buy your own machine, especially if:

You are a glass/façade contractor, industrial installer or lifting/rental company

You use spider cranes frequently throughout the year

You want full control over availability, configuration and branding (OEM logo, colours, decals)

Main differences:

Rental

Good for occasional or one-time projects

Limited choice of models and configurations

Cost accumulates over time with daily/weekly rates

Buying from a manufacturer (like SLKJCrane)

One-time CAPEX, lower cost per hour over the long term

Custom configuration: boom length, power type, safety options, attachments

OEM branding for rental companies or contractors

Direct technical support, spare parts and upgrade options

Our role as a manufacturer is not to rent spider cranes. Instead, we:

Supply spider cranes to contractors, industrial users and rental companies

Offer OEM/ODM services, including your own brand colours and logos

Provide technical selection support, drawings and documentation to help you win projects

9. Why Work with a Professional Spider Crane Manufacturer in China?

If you are planning to buy spider cranes for your business, selecting the right manufacturing partner is just as important as picking the right model.

A strong manufacturer should be able to offer:

Engineering-driven design

Complete mechanical, hydraulic and electrical design

Verified load charts, stability calculations and safety functions

Compliance with international standards

Design and production according to relevant EN/ISO/CE or regional requirements

Factory quality management, welding standards and testing procedures

Customisation capability

Different boom configurations, power systems and control options

Special attachments such as glass lifters, jibs or work platforms

Transparent communication & documentation

Clear technical proposals and quotations

Operation manuals, maintenance guides, spare parts lists

After-sales support

Online troubleshooting and training

Quick delivery of key spare parts

Support for local service partners or rental companies

When you buy spider cranes from a professional Chinese manufacturer, you can combine competitive pricing with strong engineering support, and build your own spider crane service around it.

10. Ready to Build Your Own Spider Crane Capability?

Spider cranes are no longer a niche tool. They are becoming a strategic asset for contractors, industrial users and rental companies who work in tight, complex and sensitive environments.

If you are planning to buy spider cranes and build your own lifting capability, a professional manufacturer can support you from:

Application analysis & model selection

Technical proposals & customised configuration

Manufacturing, testing and delivery

Training, documentation and after-sales service

You are welcome to contact our team for project-based selection advice and OEM/ODM spider crane solutions.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen Hu

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

FAQs About Buying Spider Cranes

A 1–3 ton spider crane is a good starting point for many glass, façade, industrial and general construction applications. Heavier 3–5 ton models are suitable if you often handle large panels, steel structures or rooftop equipment.

If you work frequently in indoor, low-emission or noise-sensitive environments (hospitals, airports, malls, residential projects), an electric or hybrid spider crane can help you win more jobs and avoid restrictions.

With proper training and a clear operation manual, an experienced crane or lifting operator can usually become familiar with spider crane controls in a relatively short time. However, operators must always respect load charts and safety rules.

Yes. As a manufacturer, we can supply spider cranes with your company colour scheme, logo and decals, which is especially important for rental companies and contractors who want strong branding.

A reliable manufacturer will provide remote technical support, training materials, spare parts support and upgrade options, helping you maximise uptime and safety over the life of the crane.

Cranes as the Backbone of Modern Steel Plants

Cranes as the Backbone of Modern Steel Plants How the Right Steel Plant Crane Solutions Drive Efficiency, Safety,

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios When people ask me about spider

How To Choose The Right Spider Crane

How To Choose The Right Spider Crane (Mini Crawler Crane) for a Project – My Practical Experience When

Low Headroom Wire Rope Hoist for Tight Workshops | SLKJCrane

Cost Saving Low Headroom Wire Rope Hoist for Tight Workshops When I visit customers’ workshops and warehouses, I

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice