Rubber Tyred Gantry Crane (RTG): Models, Power Options & Applications

Intro (short, intent-rich):

Rubber tyred gantry cranes (RTG cranes) deliver high lifting capacity with road-friendly mobility—no rails required. From precast yards and steel mills to container yards, SLKJCrane designs and manufactures industrial RTGs and container RTGs with single-beam, double-beam, and A-frame structures, plus electric and hybrid power options, anti-sway, automatic steering, and remote operation for safer, faster handling.

Related reading: RMG vs RTG—Which one fits your yard?

👉 https://www.slkjcrane.com/rmg-crane-vs-rtg-crane/

What Is an RTG Crane & When to Choose It

An RTG (rubber-tyred gantry crane) is a self-propelled gantry crane on pneumatic tyres. It moves freely across paved yards, work bays, and access roads—ideal when:

-

Site layout changes frequently or multiple work zones need to be serviced

-

Rail civil works are impractical or too costly

-

Loads must be transferred between production cells and outdoor storage

Need hoisting components? See our Electric Winch options for RTG and gantry configurations:

👉 https://www.slkjcrane.com/small-handling-equipment/electric-winch/

RTG Families at a Glance

| Solution | Best For | Typical Capacity/Layout* | Infrastructure | Opex & Emissions | Notes |

|---|---|---|---|---|---|

| Industrial MGH | Precast concrete, steel coils, wind components, bridge segments | 30–300 t; span 5–40 m; lift height 6–18 m | No rails; flexible lanes | Diesel / electric / hybrid | Cross-zone lifting; wide load shapes |

| Container RTG (Yard RTG) | Port/rail container yards | 1-over-5/6 high; up to 6–8 rows | Optional electrification | Automation options | Anti-sway, auto steering & alignment |

| Straddle Carrier (Alternative) | Fast horizontal moves of containers | Single or twin-lift | No rails | Diesel/electric | Complements RTG; different workflow |

MGH Gantry Crane

Typical pains solved: heavy, bulky, or long loads (precast girders, steel coils, molds, wind blades) where forklifts or trucks struggle with stability and aisle width.

Structure: Available in single-beam, double-beam, and A-frame portals with custom spans and clearances.

Key advantages:

-

Flexibility: No rails; reach multiple work zones with one machine

-

Efficiency: Anti-sway + precise inching for accurate set-down

-

Road-friendly: Tyre load management and steering modes for tight yards

-

Electrification options: Cable reel or conductor bar (ERTG), hybrid packs, or VSG-type gensets

Common options: coil C-hooks, spreader beams, rotating hooks, slab/grab attachments, magnet beams, wind-area reinforcement, corrosion protection.

Single Beam Rubber Tyred Gantry Crane

When to choose: medium capacities with strong cost-efficiency; great for precast yards, fabrication shops, maintenance depots.

Highlights:

-

Lower self-weight, simpler installation

-

Excellent for repetitive picks along production lines

-

Add anti-sway and wireless remote to reduce cycle time

Double Beam Rubber Tyred Gantry Crane

When to choose: higher capacities or long/heavy components where stiffness and load distribution matter (e.g., steel coils, bridge segments, heavy molds).

Highlights:

-

Higher rigidity → reduced deflection and sway

-

Wider spans with better trolley stability

-

Pairs well with specialized below-the-hook gear (coil grabs, spreaders)

A Frame Rubber Tyred Gantry Crane

When to choose: mid-to-large tonnage with higher stability demands or windy yards.

Highlights:

-

A-frame legs increase portal stability

-

Good compromise between weight and stiffness

-

Popular for bridge/infra yards and outdoor assembly lines

RTG Container Crane (Yard RTG)

Purpose-built for container yards with stacking height (e.g., 1-over-5/6) and row coverage (often 6–8).

Highlights:

-

Anti-sway & auto alignment reduce driver workload and collisions

-

Auto steering and path control improve yard throughput

-

Optional remote operation and telemetry for utilization analytics

Comparing rail-mounted gantry (RMG) vs RTG for your terminal?

👉 https://www.slkjcrane.com/rmg-crane-vs-rtg-crane/

Straddle Carrier (RTG Alternative)

A straddle carrier is not a gantry crane but a self-propelled container handler that straddles the load for quick horizontal moves and short-distance stacking. Choose SC when speed and lane agility outweigh vertical lifting flexibility. Many terminals run SC + RTG hybrids to balance horizontal flow and stacking density.

Power Systems & Retrofits (Diesel, Electric, Hybrid)

-

Diesel: lowest infrastructure demand; quick deployment.

-

ERTG (Electric RTG): cable reel or conductor bar systems—lower energy cost, lower local emissions, quieter.

-

Hybrid (battery/super-capacitor): recovers energy and downsizes gensets for fuel and noise reduction.

-

VSG-style gensets: variable-speed operation reduces off-load consumption.

Retrofit path: existing diesel RTGs can be upgraded to hybrid or full-electric where yard power is available; our team provides ROI modeling (hours/year, energy price, duty cycle, idling ratio) to estimate payback.

Core Safety & Productivity Features

-

Active anti-sway & precise inching for faster, safer set-down

-

Automatic steering & lane control to protect tyres and pavement

-

Remote operation & camera packages to enhance visibility and uptime

-

Predictive diagnostics to reduce unplanned downtime

-

Low-noise drives and advanced braking for city/industrial parks

Explore hoisting solutions and components:

👉 https://www.slkjcrane.com/electric-hoist/

Industry Applications & Mini Case Snapshots

-

Precast & Infrastructure: move girders and segments between casting beds, curing yards, and loading bays with fewer escorts.

-

Steel & Metals: handle coils, billets, slabs with dedicated grabs and magnet beams.

-

Wind & Energy: transport nacelles, hubs, and blades with controlled cornering.

-

Container & Rail Yards: stack efficiently with anti-sway and auto alignment; consider ERTG for energy savings.

Quick Selection Checklist (use in your RFQ form)

-

Max load (t) and typical load (t)

-

Span (m), clear height (m), and hook travel (m)

-

Load type & dimensions (coil, girder, mold, container, etc.)

-

Yard lanes, turning radius, ground bearing limits

-

Duty class (hours/day, picks/hour), wind/corrosion environment

-

Power preference: diesel / electric (cable reel or conductor bar) / hybrid

-

Automation: anti-sway, auto steering, remote operation, telemetry

-

Required delivery time and on-site services (install, training)

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

Get a Quote from an Engineer – share your load, span, and power preference

FAQs

If your yard layout changes or you need to reach multiple, non-aligned work zones, RTG avoids rail civil works and offers higher mobility. If you have fixed lanes and want maximum stacking density and automation on rails, consider RMG. See our guide: https://www.slkjcrane.com/rmg-crane-vs-rtg-crane/.

Common yard specs include 1-over-5/6 height and up to 6–8 container rows, depending on wheelbase and outreach. We’ll size the portal, wheel spacing, and steering modes to your lanes and pavement.

Yes. ERTG via conductor bars or cable reels is available on new builds and many retrofits. Where grid access is limited, hybrid packs or VSG-type gensets deliver fuel and noise reductions.

C-hooks for coils, magnet/spreader beams, rotating hooks, slab grabs, precast segment frames—matched to your load geometry and center-of-gravity.

See the Quick Selection Checklist above; a 30-second form speeds up engineering review.

Latest Blog

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua

10 Ton Overhead Crane Design Solution for Industrial Workshops

10 Ton Overhead Crane Design Solution: Solving Workshop Pain Points for Safer, More Efficient, and Cost Effective Lifting

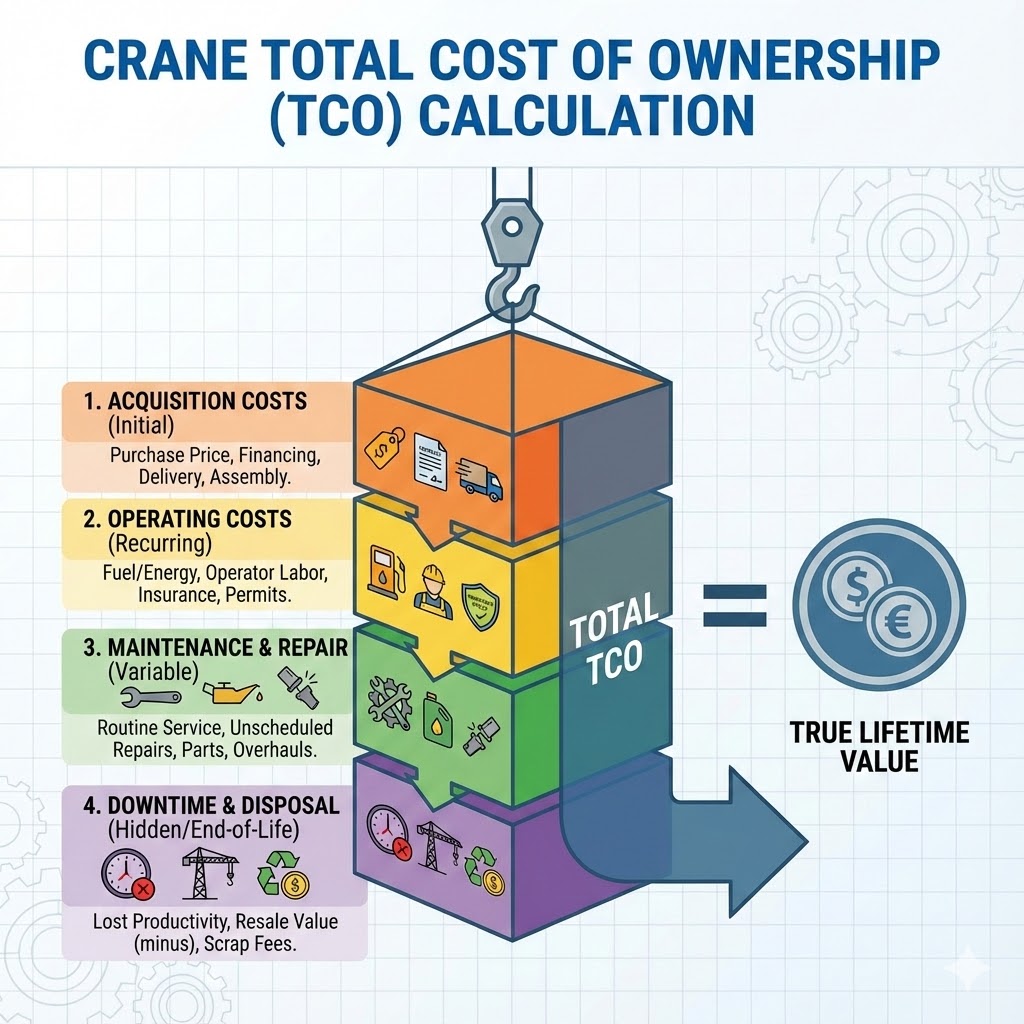

How to Calculate Crane Total Cost of Ownership (TCO)

How to Calculate Crane Total Cost of Ownership (TCO) A Practical Decision Guide for Industrial Projects in the

Cranes as the Backbone of Modern Steel Plants

Cranes as the Backbone of Modern Steel Plants How the Right Steel Plant Crane Solutions Drive Efficiency, Safety,

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios When people ask me about spider

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice