Overhead Cranes & Gantry Cranes: Selection Of Indoor And Outdoor Cranes

The global material handling equipment market will reach $317 billion by 2030, with overhead crane and gantry cranes driving 42% of industrial lifting operations. Choosing between indoor and outdoor crane systems impacts productivity, safety, and operational costs more than any other factor—this guide delivers data-driven frameworks for optimal selection.

⚙️ 1. Core Differences: Indoor vs. Outdoor Crane Engineering

Structural Design and Environmental Resistance

Outdoor cranes (Gantry/RMG types) require:

Corrosion armor: Zinc-aluminum coatings (120–200μm) for salt/moisture resistance 4

Wind resilience: Auto-braking systems activating at ≥15m/s wind speeds 3

Temperature hardening: -30°C to +50°C operational ranges with heated hydraulics 6

Indoor cranes (Bridge/Jib types) prioritize:

Space optimization: Low headroom designs (as little as 6” clearance) for warehouses 7

Precision controls: ±1mm positioning accuracy for assembly lines 10

Cleanroom compatibility: ISO Class 5 certification for semiconductor/pharma facilities 4

Operational Metrics Comparison

Table: Performance Specifications for Indoor vs. Outdoor Cranes

| Parameter | Indoor Cranes | Outdoor Cranes |

|---|---|---|

| Max Capacity | 500 tons (double girder) | 14,000+ tons (shipyard gantry) |

| Span Range | 5–40m | 10–200m |

| Lifting Height | 3–30m | 5–100m+ |

| Ambient Tolerance | 0°C to +40°C | -40°C to +60°C |

| Positioning Error | ±1–5mm | ±10–50mm |

🏭 2. Indoor Crane Systems: Types and Selection Criteria

2.1. Overhead Bridge Cranes: High-Density Industrial Workhorses

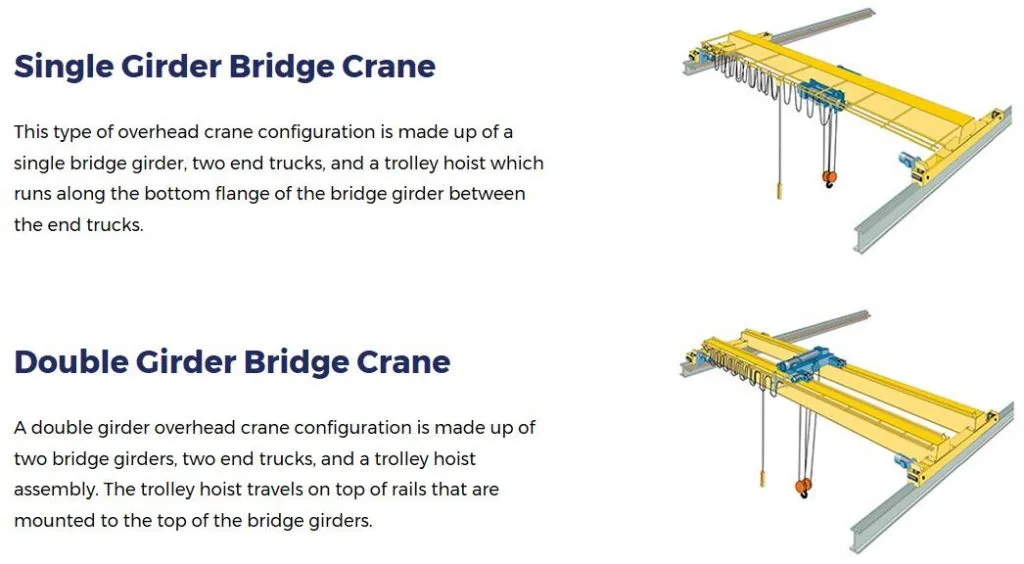

Single Girder Cranes: Ideal for light-duty tasks (≤32 tons). Cost: 30% less than double girder models with 5–25m spans.

Double Girder Cranes: Essential for heavy foundries (up to 550 tons). Feature walkable service platforms for maintenance.

Case: An automotive plant reduced part damage by 72% after installing double girder cranes with anti-sway AI

2.2. Jib and Workstation Cranes: Flexible Spot Lifting

Wall-Mounted Jibs: 180° rotation for machining cells. Handle ≤5 tons at ≤8m reach.

Freestanding Jibs: 360° coverage for loading bays. Bolt-down bases require no structural reinforcements

2.3. Monorail Cranes: Linear Process Optimization

Curved track systems: Navigate around obstacles in paint shops/assembly lines.

Load limits: ≤6 tons with VFD-controlled hoists for smooth acceleration

🌧️ 3. Outdoor Crane Systems: Ruggedized Performance

3.1. Gantry Cranes: Ports and Heavy Yards

Rubber-Tired Gantry (RTG): Diesel-electric or lithium-powered. Mobility across container blocks.

Rail-Mounted Gantry (RMG): ±5mm precision for automated terminals. Example: Rotterdam’s Maasvlakte II uses RMGs with LIDAR container scanning.

3.2. Container Handling Giants

Ship-to-Shore (STS) Cranes: 80-ton capacity at 60m outreach. Require cyclone-rated tie-downs.

Bulk Handling Cranes: Enclosed e-chains withstand coal/ore dust. Tech Spec: Igus roller chains operate 441m spans in Malaysia.

3.3. Construction Goliaths

Crawler Cranes: 3,000+ ton lifts with ground pressure <10 psi.

All-Terrain Cranes: 70km/h road speeds for multi-site projects

⚡ 4. Energy Efficiency: Cutting Operational Costs by 40%

Indoor Systems Optimization

Regenerative braking: Recaptures 18% of lowering energy in warehouses.

IE5 motors + VFDs: Reduce power consumption by 25% vs. hydraulic drives

Outdoor Electrification

Solar-powered RTGs: Port of Long Beach saves $2.1M/year with battery-electric models.

Hydrogen hybrid crawlers: 450-ton CO₂ reduction annually (e.g., Scottish wind farm projects)

📊 5. Success Stories: Real-World ROI

Indoor Case: Steel Mill Modernization (Germany)

Problem: Frequent downtime from coil-handling crane failures.

Solution: Upgraded to double girder crane with IE4 motors and predictive IoT sensors.

Results:

✓ 22% faster production cycles

✓ 60% reduction in maintenance costs

Outdoor Case: Port of Singapore Automation

Challenge: Manual RTGs caused container rehandling delays.

Solution: Deployed 27 automated RMGs with AI traffic coordination.

Results:

✓ 32% more moves/hour

✓ 70% lower labor costs

✅ 6. Selection Guide: Matching Cranes to Your Site

Indoor Facility Checklist

Headroom limits: ≤8m? Choose underslung cranes.

Floor load capacity: <5 tons/m²? Opt for top-running designs.

Process flow: Assembly lines benefit from monorails with curves.

Outdoor Site Assessment

Ground conditions: Swampy terrain demands crawlers with 1m-wide tracks.

Wind exposure: Coastal sites require anemometers + auto-shutdown.

Duty cycles: High-frequency ports need 24/7-rated RMGs.

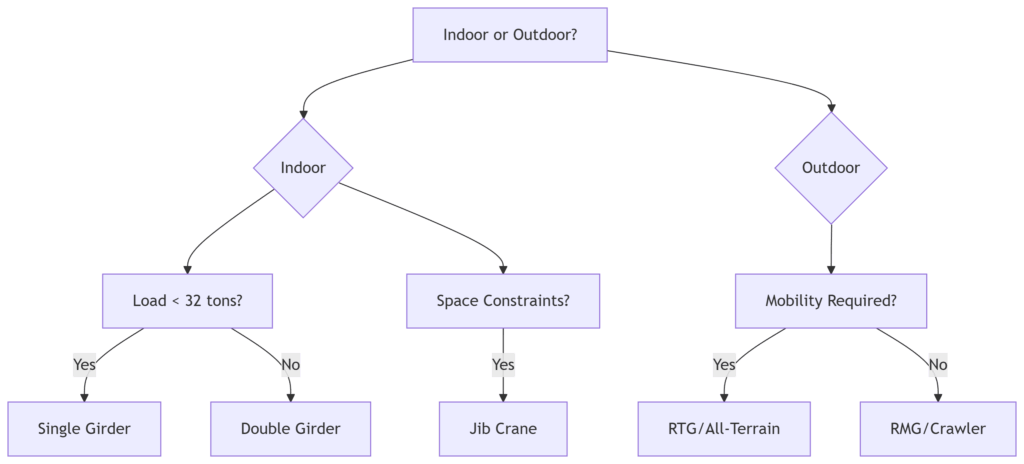

Decision Tree: Crane Selection Algorithm

🚀 7. Future-Proofing: Automation and Retrofits

Indoor Smart Upgrades

AI collision avoidance: Reduces damage claims by 90% in auto plants.

Digital twin monitoring: Predicts wire rope fatigue 500 hours pre-failure.

Outdoor Autonomy Trends

5G remote operation: Port operators control RTGs from centralized hubs.

Hydrogen retrofit kits: Convert diesel gantry cranes to zero-emission by 2027.

💎 Conclusion: Strategic Investment Framework

For Indoor Facilities:

Prioritize precision + space efficiency. Double girder cranes dominate heavy manufacturing, while modular jibs excel in flexible cells. Invest in VFDs and regenerative drives for ≤2-year payback periods.

For Outdoor Sites:

Focus on durability + mobility. RTGs deliver flexibility in multi-zone terminals, while RMGs maximize density in high-volume ports. Electrification cuts lifetime costs by 41% vs. diesel

Final Tip:

8% of crane failures stem from improper sizing. Use free load chart analysis from manufacturers like Maxim Crane Works to prevent overloading.

“The right crane isn’t just equipment—it’s your production multiplier. Indoor precision and outdoor resilience now define competitive advantage.”

—Global Lifting Journal, 2025 Industry Report

FAQs: Indoor vs. Outdoor Cranes

Q: Can outdoor cranes be used indoors?

A: Only with CE-compliant emissions control (e.g., electric RTGs). Diesel units require 45 ACH ventilation.

Q: What’s the lifespan difference?

A: Indoor cranes last 25–30 years; outdoor models 15–20 years due to environmental stress.

Q: How critical is crane modernization?

A: Retrofits boost efficiency by 30%+ and cut energy costs by 40%

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice