2025 Egypt Overhead Crane Buying Guide: Price, Suppliers and Selection Tips

As Egypt keeps investing in industry and infrastructure in 2025, demand for overhead cranes in steel plants, oil & gas, fabrication workshops, logistics warehouses and ports continues to grow.

For owners, EPC contractors and purchasing managers, an overhead crane is not a “one-time consumable”. It usually works in the plant for 10 years or more. Choosing the right crane type and supplier will not only affect the purchase price today, but also your safety, efficiency and maintenance costs in the coming decade.

Typical questions we hear from Egyptian buyers:

Why can quotations for “the same overhead crane” differ by 20–40%?

From 1 ton to 50 tons, how should I choose between single girder, double girder and European type?

Should I buy from a local crane supplier in Egypt, or import from China?

What data do I need to prepare before asking for a quote, so that suppliers do not simply “guess a price”?

This 2025 Egypt Overhead Crane Buying Guide focuses on six core topics:

Selection – Price – Supplier choice – RFQ parameters – Total cost control – FAQ & marketing tips

so you can make a clear, professional decision before you invest.

1. Selection principles: “matched to your duty”, not “the bigger the better”

An overhead crane is safe and economical only when it matches your real working conditions. A well-matched crane:

works safely with enough margin,

avoids structural over-design,

reduces building and steel structure cost,

and is easier to maintain in the long run.

1.1 Capacity & structure: 1–20 t single girder, 10 t+ heavy duty prefer double girder

For heavy duty or high-frequency use (10 t and above)

For steel service centres, coil warehouses, mould shops, steel mills and casting plants, a double girder overhead crane is normally the better choice:

two main girders = higher stiffness and less deflection,

easier to achieve larger lifting height,

better suited for grabs, lifting beams, magnets, rotating hooks and other heavy-duty attachments,

more safety margin for continuous operation.

、

👉 Simple rule of thumb:

Daily handling → single girder

Heavy load + high frequency + strict safety → double girder

This avoids wasting money on an unnecessarily heavy structure for light-duty work.

1.2 Building and space: suspension for low space, top-running for wider spans

Your building structure and clear height are often the first constraints.

Top-running overhead crane – for medium & large spans

Crane runs on rails fixed on steel columns or runway beams.

Suitable for spans like 18 m, 22 m, 30 m and above.

Capacity can range from a few tons up to hundreds of tons.

Best choice for new steel buildings, logistics warehouses, heavy workshops.

If you are still designing the building, it is smart to involve the crane supplier early so that runway beam size, column spacing and roof height are coordinated from the beginning.

1.3 Prefer low energy & low maintenance? Consider European / FEM standard cranes

For plants that run long hours every day and require high stability, a European type / FEM standard overhead crane is usually more economical over its full life:

more compact main girder and end carriage design,

lower self-weight and wheel loads,

most motions driven by frequency inverters,

smoother start / stop, less impact on runway and structure,

higher-grade motors, gearboxes and electrical components,

longer service life and longer maintenance intervals.

Although a European overhead crane may have a slightly higher purchase price, it often saves more in:

energy consumption,

maintenance labour and spare parts,

and reduced downtime.

1.4 Special environments: explosion proof, high temperature, anti corrosion

In Egypt, the following conditions are very common. Using a standard crane here is a big risk:

Key idea:

In special environments, you must use a special crane design.

Otherwise you are gambling with safety and crane life.

2. Overhead crane price in Egypt: what really drives the cost?

Many buyers first ask: “How much does an overhead crane cost in Egypt?”

In reality, there is no fixed price list. The overhead crane price in Egypt is driven by several technical and commercial factors, not only by the tonnage.

2.1 Main factors that affect overhead crane price

Typical cost drivers include:

Capacity (tonnage)

Span and lifting height

Duty class / working hours (A3, A5, A6, etc.)

Design standard (Chinese standard vs European / FEM / DIN)

Hoisting mechanism type (electric hoist vs open-winch trolley)

Control method (pendant, radio remote, cabin, or combinations)

Frequency control (VFD for hoisting and travelling, or not)

Special design (explosion-proof, high-temperature, anti-corrosion, outdoor with storm-clamps, etc.)

Whether the quotation includes rails, power supply, runway beams

Whether it includes installation, commissioning, training and inspection

In general:

For the same capacity, longer span and higher lifting height cost more.

Higher duty class and full-VFD drives increase initial price but improve performance and life.

Explosion-proof, high-temperature and anti-corrosion designs add cost, but they are essential for safety and compliance.

2.2 Typical capacity & span bands (1–50 t) – how buyers often group budgets

Instead of giving hard numbers, it is more useful to think in budget bands:

(1) Entry level: 3–5 t single girder, 12–18 m span

Light duty single girder overhead crane.

Used in small machine shops, packing areas, small warehouses.

Simple configuration, basic but reliable, no complex options.

Suitable as an “entry-level investment” for smaller factories.

(2) Mid range: 10–20 t double girder, 18–28 m span

For medium-heavy workshops, steel structure fabrication, mould shops, coil handling.

The crane is often part of the core production process, not just occasional lifting.

Requirements for smooth running, accurate positioning, braking performance, lifting height and duty class are much higher.

Often equipped with variable frequency drives and better electrical components.

(3) Heavy range: 20–50 t double girder, 20–32 m span

For steel mills, foundries, heavy equipment manufacturing, heavy storage yards.

Designed for heavy load + continuous duty, with more safety redundancy.

Uses higher-grade motors, gearboxes, brakes and control systems.

Requires stronger runway beams, columns and foundations – total project cost is higher.

Even within the same capacity band, a European-type double girder crane with full VFD, anti-sway and remote monitoring will naturally be more expensive than a basic traditional model – but its life-cycle performance is also on a different level.

3. Local Egypt suppliers vs Chinese overhead crane manufacturers: how to choose?

For buyers in Egypt, there are usually two routes:

Buy from a local overhead crane supplier in Egypt, or

Import from Chinese manufacturers with export experience.

Both routes can work well. The key is to match them to your project type, schedule and budget.

3.1 Local suppliers: easy communication & fast on-site service

Advantages:

Same language and time zone → easy daily communication.

Familiar with local regulations, inspection routines and some project rules.

Faster response for on-site maintenance and annual inspection.

Potential limitations:

Product range for special cranes (explosion-proof, high-temperature, low-headroom, European type) may be limited.

Manufacturing scale may be smaller, so cost control is not always optimal.

For large or complex cranes, critical components may still be imported.

Best for:

Projects where service convenience is the top priority, tonnage is not very high, and configuration is relatively standard.

3.2 Chinese manufacturers: strong cost advantage and complete product range

Chinese overhead crane manufacturers have clear strengths in product variety, cost control and export experience:

Full range from 1 t electric hoist cranes up to 300 t+ ladle cranes.

Mature solutions for European cranes, low headroom cranes, explosion-proof cranes, steel mill cranes, magnetic / grab cranes, etc.

Rich export experience to Egypt and the Middle East, understanding of 380–415 V / 50 Hz power, documents for customs clearance and 3rd-party inspection.

By working with an experienced Chinese supplier, you can often:

Get a more competitive overhead crane price in Egypt for the same configuration.

Have more choices for special environments and customised designs.

Combine remote technical support with local installation partners to solve service issues.

3.3 Practical model: Chinese complete crane + local Egyptian installation / inspection

In many real projects, a very balanced and popular solution is:

Purchase the complete crane from China (mechanical + electrical),

then use Egyptian teams for installation, commissioning and inspection.

This way you can:

enjoy competitive pricing and full product range from China,

use local teams who know Egyptian regulations, safety rules and inspection routines,

and still receive remote support, drawings and online guidance from the manufacturer.

For very large or complex projects, you can also invite a Chinese engineer to assist on-site at key stages, working together with the local erection team.

4. RFQ checklist: information you must include in your enquiry

The more complete your enquiry, the faster and more accurate the supplier’s proposal and quotation will be. For an overhead crane project in Egypt, you should prepare at least the following data.

4.1 Basic project information

Project city / location (Cairo, Alexandria, etc.)

Industry and application (steel structure, coil warehouse, fabrication shop, steel mill, petrochemical, etc.)

New building or existing plant / renovation project

4.2 Core technical parameters

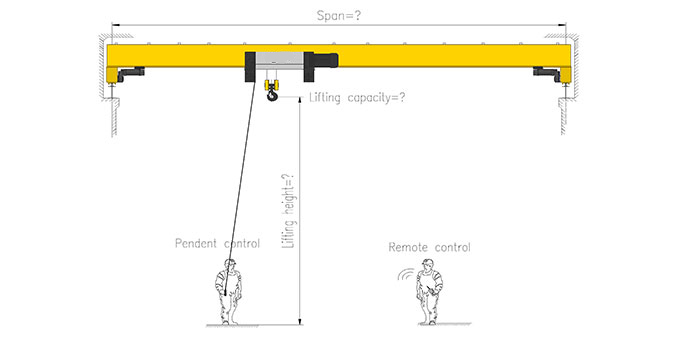

Lifting capacity (max working load), and whether you plan for future expansion

Span (distance between runway rails / columns)

Lifting height (from floor to hook highest position; indicate any pit if applicable)

Runway length (effective travelling length of the crane)

Duty class / working hours (hours per day, approximate cycles per hour)

4.3 Load type and working conditions

Type of load: steel coils, plates, profiles, machinery, moulds, ladles, etc.

Indoor or outdoor; temperature range; dust level; humidity; salty or corrosive atmosphere.

Any need for explosion-proof, high-temperature or anti-corrosion design.

4.4 Power supply and control method

Power supply: e.g. 380–415 V / 50 Hz, 3-phase

Control: pendant, radio remote, cabin, or combined control

Need for VFD control, anti-sway, synchronised control, remote monitoring, etc.

4.5 Standards and other requirements

Preferred design standard: Chinese standard, European / FEM / DIN, etc.

Whether you need the supplier to provide rails, power supply system, runway beams.

Whether third-party inspection (BV, SGS, etc.) is required.

If you send this checklist to 2–3 experienced suppliers, you can usually receive solid technical proposals and quotations within 1–2 rounds of communication, and compare them effectively.

5. How to reduce your 5–10 year total cost, not just the purchase price

A smart buyer does not only push for a low initial price. The real goal is to minimise the total cost over 5–10 years.

5.1 Avoid “over-sizing”: choose capacity and duty class based on real needs

Some projects like to “play too safe” and double the capacity:

for example, working load is 10 t, but they insist on a 20 t crane.

However:

When capacity goes up, everything becomes heavier: main girders, end carriages, motors, brakes, runway beams and foundations.

Steel structure and energy consumption both increase significantly.

It is better to:

Define your real maximum load, add a reasonable safety margin,

and choose capacity and duty class together with a professional engineer.

This is much more economical than blindly going “two sizes up”.

5.2 Use low-headroom design to cut building modification cost

For existing plants or buildings with limited height, instead of raising the roof or digging pits, you can:

choose a low-headroom single girder or double girder design,

optimise the position of the hoist and trolley,

significantly increase available hook height without changing the building.

In many projects, the money saved in civil works and steel structure is greater than the extra design cost of a low-headroom crane.

5.3 Fix technical details early to avoid rework

Clearly describe your working environment, load type and future expansion plans.

Confirm control methods, safety functions, power supply and standards before signing.

Avoid modifying structures or electrical systems after the crane arrives on site.

One round of clear technical communication at the beginning is much cheaper than on-site “cut and repair” later.

5.4 Prepare spare parts in advance to reduce downtime

The crane structure itself rarely fails. Most issues come from:

brake linings and coils,

wire ropes and pulleys,

limit switches and contactors,

inverters and small control components.

It is strongly recommended to:

ask the manufacturer to provide a 1–2 year spare parts list,

purchase at least the key wear parts together with the crane or soon after installation.

Then your local maintenance team can fix issues quickly, without waiting weeks for international shipments.

6. Why work with experienced Chinese overhead crane suppliers for Egypt?

You can keep this section slightly branded later (add your company name and contact), but the logic stays the same.

6.1 Not only a cheaper crane – a better total project “equation”

From real projects with Egyptian customers, choosing an experienced Chinese overhead crane manufacturer often helps you save money and trouble in three areas:

More competitive crane price for the same configuration

Same capacity, same duty class and similar components, but more competitive price.

Full product range: single girder, double girder, European type, explosion-proof, high-temperature, anti-corrosion, steel mill cranes, etc.

More controllable building and steel structure cost

Lighter self-weight and lower wheel loads with European / low-headroom designs.

Early participation in building layout can help optimise runway beams and foundations, saving steel and civil work.

More stable long-term operation with less downtime

Unified selection of key components makes spares easier to manage.

Combination of remote diagnostics and local partners gives faster problem solving.

In short, a good supplier is not just selling you “one crane”,

but helping you optimise the whole lifting system + building + maintenance economics.

6.2 Five points to check when choosing a Chinese partner

When you are comparing several suppliers, use these 5 checks:

Proven references in Egypt or the Middle East

Can they show real projects in Egypt, Saudi Arabia, UAE, etc., with photos and technical data?

Free selection and layout suggestions

Are they willing to help you with crane layout, hook coverage, runway arrangement based on your drawings?

Professional and transparent technical proposal

Does the quotation clearly state capacity, span, lifting height, duty class, design standard, and brands of key parts?

1–2 year spare parts strategy

Do they provide a recommended spare parts list and stock quantity for 1–2 years of operation?

Clear after-sales response commitment

Do they give written response times (e.g. 24-hour remote response) and clarify how on-site service would be arranged and charged?

If a supplier meets these points, they are likely to be a long-term partner, not just a one-time seller.

6.3 Clear next step – what you can send to start a professional discussion

If you are planning an overhead crane for your project in Egypt, you can start simply by preparing:

project location and industry,

required capacity, span and lifting height,

building drawings or a simple sketch with main dimensions,

load type (coils, plates, equipment, ladles, etc.) and daily working hours.

Send this information to the supplier you trust, and ask for:

1–2 alternative technical proposals for comparison,

estimated overhead crane price in Egypt and delivery time,

optimisation suggestions for high temperature, dust and possible corrosion in your site.

Then you can use these proposals as a benchmark when talking to other suppliers.

It will be much easier to judge who is more professional and whose quotation is more reasonable.

7. Conclusion: in Egypt, choose the right crane first, then the cheapest one

For owners and buyers in Egypt, the overhead crane decision can be summarised in two sentences:

Clarify your working conditions, building and usage needs before talking about brand and price.

Choose the right crane type and supplier first, then compare who really gives you better value.

If you:

avoid over-sizing and mis-matching,

understand design standards and configurations behind the price,

balance local service and Chinese manufacturing advantages,

and send a complete RFQ with key parameters,

then whether you need a 5 t crane for a small workshop or a 50 t crane for a steel plant, you can find the best balance between cost, safety and efficiency for your project in Egypt.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

FAQ – common questions from overhead crane buyers in Egypt

A: The full process includes:

technical discussion → quotation → contract → design & production → factory testing → sea shipment to Egypt → on-site installation & commissioning.

For standard cranes and common capacities, production usually takes from a few weeks up to about two months.

For special cranes (explosion-proof, ladle cranes, high-temperature or very large capacity), production may take longer.

Adding sea freight and on-site installation, the total lead time is usually several weeks to a few months.

It is wise to treat delivery time as an important technical parameter and discuss it at the very beginning.

A: Yes, a supplier can give you a budget price range based on rough data.

However, to get a firm and accurate quotation, you still need to confirm:

exact span, lifting height and runway length,

working hours and usage frequency,

load type, environment, building structure.

A professional approach is:

First get a budget proposal based on rough data;

Then, after you send building drawings or simple sketches, you receive a final technical solution and fixed quotation.

A: High temperature and dust do affect crane life and failure rate. That is why we normally:

increase protection level of motors and panels,

improve sealing and ventilation of control cabinets,

use suitable cables, paints and protection systems for high-temperature and dusty environments,

recommend more frequent cleaning and lubrication in the maintenance plan.

The extra cost of such improvements is usually small compared with the crane price, but they are very important for long-term reliability and safety.

If you explain your environment in detail, the supplier can design a solution that actually helps you save money in the long run.

A: There are three typical options:

Use FOB / CIF terms – you or your local forwarder handle customs clearance and inland transport.

Use DDU / DDP terms – the Chinese supplier and their logistics partner deliver the crane to your site, including customs clearance.

You appoint a forwarder experienced in Egypt business; the manufacturer prepares all documents and cooperates fully.

Experienced exporters normally provide packing list, commercial invoice, certificate of origin and related certificates to make customs clearance smoother.

A: Today, most projects in Egypt use a combination of local service + remote technical support:

Faults are first diagnosed by phone, email or video call.

The manufacturer guides your maintenance team or local partner to replace parts or adjust parameters.

For serious issues, you can agree in advance whether engineers will travel to site.

Again, we recommend you purchase 1–2 years of key spare parts together with the crane, so most problems can be solved on site without long waiting times.

A: Looking only at the total price is dangerous. A better method is to compare:

design standard (traditional vs European / FEM), duty class and VFD configuration,

crane self-weight and maximum wheel load,

brands of motors, gearboxes and electrical components,

whether rails, power supply, installation, commissioning and training are included,

spare parts list and spare parts prices.

Make a simple comparison table for 2–3 suppliers with these items.

You will quickly see who is truly cost-effective, not just “cheap”.

A: It depends on how the crane is designed at the beginning.

If span, lifting height, duty class and runway design consider future expansion, you can often add extra runway length, another crane, or more advanced control later.

If the initial design is only just enough for current needs, heavy expansion may require a new crane.

So if you have clear expansion plans, tell your supplier from day one.

Many layout and crane design choices can be optimised to support future growth and reduce repeated investment.

Latest Blog

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua

Free Standing Gantry Crane Solutions | SLKJCrane

Free Standing Gantry Crane Solutions for Existing and Leased Buildings Why Many Workshops Struggle to Install an Overhead

Shipbuilding Gantry Crane vs General Gantry Crane

Shipbuilding Gantry Crane vs General Gantry Crane: 7 Key Design Differences In many projects we hear a similar

Shipbuilding Gantry Cranes by Ship Type | Capacity & Span Guide

Shipbuilding Gantry Cranes for Different Ship Types – Capacity, Span and Configuration Guide | SLKJCrane In modern modular

Intelligent Warehouse Overhead Crane 1–20 Ton | Heavy-Duty AS/RS Solutions

Intelligent Warehouse Overhead Crane for Heavy-Duty AS/RS | SLKJCrane In heavy-duty warehouses such as steel coil storage, mold

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice