Technical Specifications of Single Girder Electric Hoist Cranes

I. Single Girder Electric Hoist Cranes Definition and Structural Features

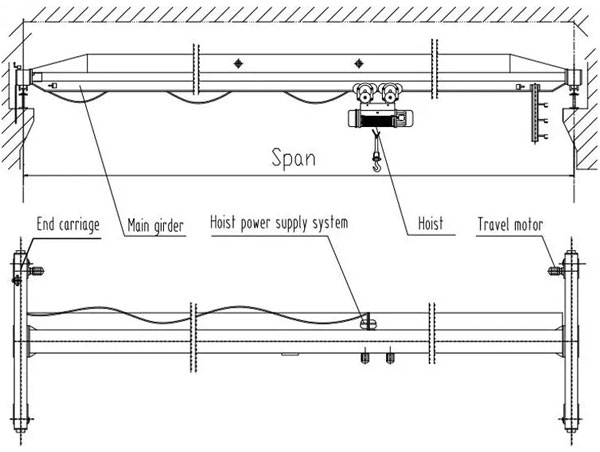

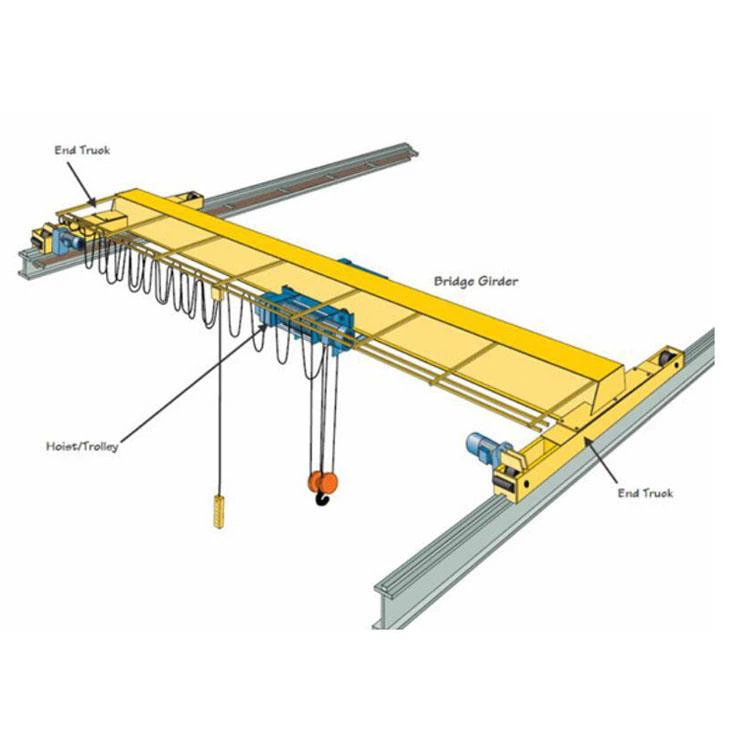

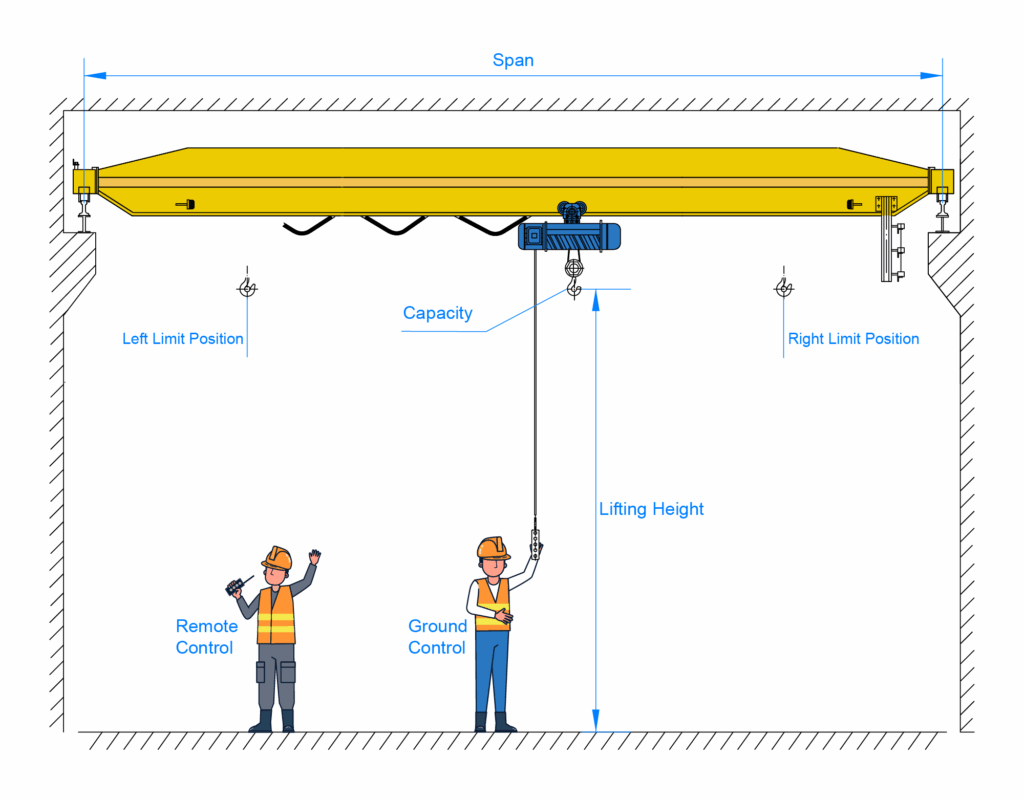

A single girder electric hoist crane is an overhead lifting device that utilizes an electric hoist as its core lifting mechanism. It consists of a single main girder (I-beam or box-type structure), end carriages, travel mechanisms, and an electrical control system. Key characteristics include:

- Lightweight Design: Modern models use 16Mn steel or European-style box girders, reducing weight by 30% compared to traditional double-girder models, making them ideal for standard factory floor load requirements;

- Modular Assembly: High-strength bolted connections between the main girder and end carriages enable rapid assembly for spans of 6-30 meters, cutting installation time by 40%;

- Smart Integration: 2025 models feature CANbus communication protocols for seamless integration with Industrial IoT (IIoT) platforms

II. Core Technical Features

1. Electric Hoist System

- Multi-Type Compatibility: Supports CD/MD wire rope hoists (0.5-10t),XN series chain hoists, and explosion-proof configurations;

- Dual-Speed Control: MD-type hoists operate at standard (8m/min) and micro-speed (2m/min) modes, achieving positioning accuracy of ±5mm;

- Safety Redundancy: Dual braking systems (mechanical + electromagnetic) with 110% overload automatic cutoff.

2. Drive and Control System

- Frequency Conversion Technology: Adjustable trolley travel speed (20-40m/min), reducing startup impact by 60%;

- Human-Machine Interface: Bluetooth remote control and mobile app operation with real-time load display and fault diagnostics

III. Typical Applications

| Industry | Configuration | Technical Highlights |

|---|---|---|

| Automotive Manufacturing | 3t/15m span + cleanroom model | Dustproof sealing (compliant with ISO Class 8 standards) |

| Chemical Storage | 5t/20m span + ExdII BT4 explosion-proof certification | Stainless anti-corrosion coating + grounding resistance ≤0.1Ω |

| Cold Chain Logistics | 2t/12m span + -30°C low-temperature kit | Cryogenic lubrication system + condensation-resistant electrical components |

IV. Operation and Maintenance Guidelines

Routine Inspections

- Check wire rope wear every 50 operating hours (allowable wear <10% of original diameter);

- Test emergency brake response weekly (standard value <0.5 seconds);

Periodic Maintenance

- Annual inspection: Includes main girder deflection test (mid-span ≤ S/700) and rail straightness calibration (±3mm/m);

- Critical component lifespan: Wire ropes (≥20,000 cycles), gearbox lubricant (2,000-hour replacement interval)

V. 2025 Technological Trends

- Energy Efficiency: IE4 motors + regenerative braking systems reduce energy consumption by 25%;

- Digital Twin: OPC UA protocol enables virtual-physical synchronization, boosting predictive maintenance accuracy to 92%;

- Extreme Environment Adaptation: Specialized models for -40°C Arctic and +60°C high-temperature operations

Conclusion

Electric single girder cranes and double girder bridge cranes cater to different operational scales and industries. While single girder models offer affordability and space efficiency for light-duty tasks, double girder bridge cranes deliver unmatched power and durability for heavy lifting. By evaluating your load demands, workspace, and long-term goals, you can select the crane that maximizes productivity and safety.

All News

Recent Posts

2025/1/25

2025/2/7

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice