Metallurgical Wire Rope Hoist for Steel Mills & Foundries

Safe, Reliable Lifting in High-Temperature, Heavy-Duty Environments

In steelmaking, casting and rolling workshops, the working environment is far beyond what a standard electric hoist can handle:

Radiant heat from ladles, ingots and red-hot billets

Heavy dust, fumes and splashes

Long working hours with frequent starts and stops

High safety requirements and strict downtime control

Under these conditions, a common wire rope hoist will quickly run into trouble: brake fading, wire rope annealing, motor overheating, repeated trips and frequent failures.

If you want stable, long-term lifting with lower risk and lower lifecycle cost, you need a hoist that is engineered specifically for these conditions – a metallurgical wire rope hoist.

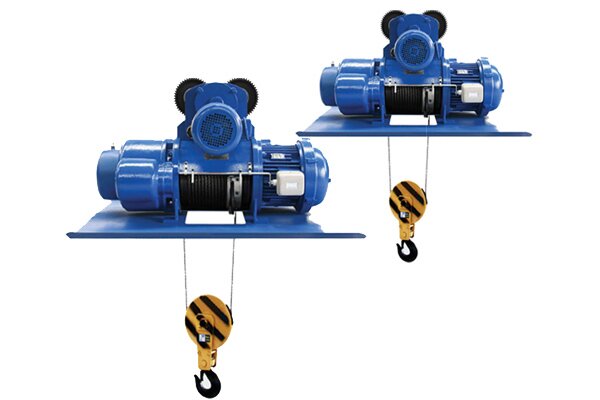

What Is a Metallurgical Wire Rope Electric Hoist?

A metallurgical wire rope hoist is a specially engineered electric wire rope hoist designed for high-temperature, heavy-duty and high-risk environments in the steel and foundry industries. It is typically used in:

Steel mills: handling steel ladles (with special design), ingots, billets and semi-finished products

Foundries: lifting sand boxes, molds and castings for pouring, stripping and assembly

Continuous casting & rolling shops: transferring billets, slabs, steel coils and bundles

Compared with a standard wire rope hoist, a metallurgical hoist features:

Enhanced high-temperature resistance

Multi-layer safety redundancy

Higher duty classification (M6 and above)

Structural and electrical protection against dust, heat and splashes

Flexible customization to match different processes and crane types

It can be designed and verified according to applicable standards (such as GB/T 3811 and related metallurgical crane codes), to meet the safety and reliability requirements of steel plants and foundries.

Key Advantages of a Metallurgical Wire Rope Hoist

1. Outstanding High-Temperature Protection

Steelmaking and casting lines generate strong radiant heat. A standard hoist quickly suffers from thermal damage. A metallurgical hoist includes a complete high-temperature protection system:

Thermal insulation plates

Special heat shields are installed at key positions (such as hoist body and hook block) to block radiant heat from ladles, ingots and red-hot billets, protecting internal components.High-temperature motor (H-class insulation)

The motor uses H-class or equivalent insulation materials for windings, slot liners and leads. It is designed to run stably even when ambient temperature exceeds 60°C, significantly reducing the risk of motor burnout.Metallurgical wire rope

The hoist adopts a special construction wire rope with treated steel core. It offers better resistance to high temperature and avoids premature annealing or strength loss under radiant heat.High-temperature flexible cables

Heavy-duty silicone rubber cables are used, typically with temperature resistance up to around 180°C. They provide excellent flexibility, anti-aging performance and reduced cracking or failure under heat and motion.High-temperature-rated electrical components

Contactors, relays and other electrical parts are selected for metallurgical service, ensuring reliable performance under high ambient temperature, dust and frequent operation.

In short: a metallurgical hoist is designed to survive and work reliably in heat where a standard hoist would quickly fail.

2. Multi-Layer Safety Redundancy – Protecting People and Equipment

In a steel plant or foundry, one failure can lead to a serious accident. That is why metallurgical wire rope hoists are built with multiple safety layers:

Dual braking systems

The hoisting mechanism is equipped with two independent brakes. If one brake fails, the other can still safely hold the load, preventing uncontrolled lowering.Multi-stage limit protection

Normal up and down limit switches

Emergency or ultimate limit protection

These protect against hook over-travel, rope slack and other dangerous positions.

Overload protection (load limiter)

A load limiter continuously monitors the lifted load. If the actual load exceeds the rated capacity, it will alarm and stop hoisting to prevent overload operation.High safety factor on wire rope and hook

Metallurgical-grade wire ropes usually adopt a safety factor ≥ 5, and hook blocks are designed to higher safety standards, providing ample strength margins for critical load-bearing parts.Complete electrical protection

Protection functions such as overload, overcurrent, undervoltage, phase loss and wrong phase sequence are included to avoid damage or uncontrolled movement caused by power supply issues.

These safety measures work together to ensure high reliability and low risk in harsh metallurgical applications.

3. High Duty Classification for Heavy Cycles

Steel and foundry workshops often run multiple shifts with long daily operating hours. Lifting devices must withstand frequent starts, stops and heavy loads.

A metallurgical wire rope hoist is therefore:

Designed to duty class M6 or above, suitable for heavy-duty, high-frequency operations

Equipped with hoisting motors, gearboxes and mechanisms selected specifically for high duty, with larger thermal capacity and stronger structure

Available with variable frequency drive (VFD) for hoisting and cross travel:

Smooth acceleration and deceleration

Reduced impact and structural fatigue

Better load control and positioning

Where required, anti-sway and precise positioning functions can be added to increase handling efficiency and operational safety.

For the user, this means:

Fewer unplanned shutdowns

Lower maintenance and spare parts cost

More stable production rhythm and better productivity

4. Robust Construction and Environment Protection

To cope with dust, fumes, humidity, oil mist, corrosion and splashes, metallurgical hoists can be equipped with:

Dust-proof and splash-proof enclosures for electrical and mechanical parts

High-temperature and anti-corrosion coating on metal surfaces to slow down rust and aging

Protective covers and guards to shield against steel splashes, slag and sparks

This makes the hoist more durable and reliable under severe environmental conditions.

5. Tailor-Made Solutions for Your Process

Every steel plant and foundry has its own process layout and lifting requirements. We can tailor the metallurgical wire rope hoist to your project, for example:

Different configurations for single-girder or double-girder metallurgical cranes

Various lifting attachments: hooks, tongs, clamps, beams, tilting devices, etc.

Multiple control options: pendant control, radio remote, cab control or centralized control

Integration with the crane system, workshop interlocks, MES or plant-level systems for:

Interlocked safety functions

Load and cycle monitoring

Remote diagnostics and data recording

Typical Technical Configurations & Working Conditions

Below are some reference configurations of metallurgical wire rope hoists. Final selection will be based on your actual requirements.

| Rated Capacity (t) | Lifting Height (m) | Hoisting Speed (m/min) | Trolley Speed (m/min) | Duty Class | Typical Working Conditions |

|---|---|---|---|---|---|

| 5 | 6–12 | 4 / 8 (single speed or VFD) | 20–30 | M5–M6 | Molds, sand boxes and tools in foundry |

| 10 | 6–16 | 4 / 8 (VFD adjustable) | 20–32 | M6 | Billets, castings, fixtures and tools |

| 16 | 6–20 | 3.5 / 7 | 20–32 | M6 | Heavy-duty workstation service in steel shop |

| 20 | 8–20 | 3.5 / 7 | 20–32 | M6–M7 | Ingots, coils and heavy components handling |

Note: The parameters above are typical examples. Actual design will be calculated and verified based on:

Capacity and lifting height

Crane span and runway layout

Ambient temperature and radiant heat intensity

Required duty cycle and operating mode

Metallurgical Wire Rope Hoist vs. Standard Wire Rope Hoist

| Item | Standard Wire Rope Hoist | Metallurgical Wire Rope Hoist |

|---|---|---|

| Ambient temperature | Typically −20 to +40°C | Suitable for high-temperature areas, 50°C and above |

| High-temperature protection | No special insulation | Heat shields, high-temp cables, motor and electrical design |

| Duty class | Mainly M3–M5 | M6 and above for heavy-duty, high-frequency work |

| Safety redundancy | Single brake, basic limits | Dual brakes, multi-stage limits, overload protection |

| Failure rate & service life | Higher failures in hot environments | Designed for metallurgical duty, longer service life |

| Lifecycle cost | Lower purchase price, higher maintenance cost | Slightly higher purchase price, lower total lifecycle cost |

For real metallurgical environments, choosing a standard hoist is a hidden risk, while a metallurgical hoist is a rational, long-term investment.

Typical Applications & Project Benefits

Metallurgical wire rope hoists are widely used in:

Steelmaking plants: ladle bay auxiliaries, ingot handling, charge preparation

Foundries: pouring lines, molding lines, sand handling, mold assembly

Rolling mills: billet feeding, coil handling, finished product bays

Alloy production and heat-treatment lines in other high-temperature industries

Typical benefits for users include:

Reduced equipment failures and unplanned downtime

Lower risk of accidents caused by lifting device failure

Longer life of key components and lower spare parts consumption

Higher lifting efficiency and more stable production rhythm

Higher safety level and better overall automation capability

If needed, we can provide a complete engineering package for your project, including:

Working condition assessment

Technical proposal and layout drawing

Detailed parameter sheet and quotation

How to Choose the Right Metallurgical Wire Rope Hoist

To help us recommend the most suitable hoist configuration, you only need to prepare a few basic data:

Rated capacity (t) – e.g. 5t, 10t, 16t, 20t

Lifting height (m) – from floor level to highest hook position

Crane type and runway – single/double girder, rail type, span and workshop layout

Working environment

Furnace front or general area?

Ambient temperature range and radiant heat level?

Dust, humidity, corrosive gas or oil mist?

Duty cycle

Working hours per day and number of shifts

Average lifting cycles per hour and average load percentage

Control mode

Pendant, radio remote, cab or centralized control

Any additional functions required:

Frequency control, anti-sway, precise positioning

Remote monitoring or data logging

Don’t worry if you cannot define everything yet.

Just send us:

Some photos of the workshop and lifting area

The type and weight range of the loads

A simple layout sketch or main dimensions

Our engineering team will prepare a professional and cost-effective metallurgical hoist solution for you.

Make Your Metallurgical Lifting Safer, More Reliable and More Efficient

In high-temperature, high-risk metallurgical environments, lifting equipment is much more than a simple tool – it is the key link between heat and power, risk and safety.

A properly designed metallurgical wire rope hoist will:

Operate reliably where standard hoists fail

Reduce the risk of accidents and downtime

Lower your total lifecycle cost

Support your production with stable, efficient lifting operations

If you are planning a new steel or foundry project, or upgrading existing cranes in a hot and heavy-duty workshop, we are ready to support you.

👉 Contact SLKJCrane today for a free consultation and quotation.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen Hu

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

FAQ: Metallurgical Wire Rope Hoists

A: Ladle handling has the highest safety requirements. Whether this hoist can be used directly depends on the specific design and safety redundancy. We can provide dedicated ladle handling solutions with detailed safety calculations according to your local standards and regulations.

A: In general, the hoist can operate in high-temperature metallurgical environments above 50°C. For furnace-front or extreme radiant heat areas, we will evaluate the temperature field and design special protection. The final proposal will clearly state the allowable temperature range.

A: If your plant has explosive dust or gas, we can design explosion-proof metallurgical hoists according to the required Ex rating, including explosion-proof motors, electrical components and structure. Please specify your required standard and zone/class.

A: The hoist is designed with easy maintenance in mind. Key components use standardized parts where possible. We provide a full spare parts list and maintenance manual, and can offer on-site commissioning and remote technical support when required.

A: We can consider your future expansion plans during the design stage and reserve an appropriate margin. If you upgrade your crane or increase duty level later, we can also provide upgrade and retrofit solutions for the existing hoists.

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios When people ask me about spider

How To Choose The Right Spider Crane

How To Choose The Right Spider Crane (Mini Crawler Crane) for a Project – My Practical Experience When

Low Headroom Wire Rope Hoist for Tight Workshops | SLKJCrane

Cost Saving Low Headroom Wire Rope Hoist for Tight Workshops When I visit customers’ workshops and warehouses, I

Spider Crane Guide 2025 | Types, Specs & Applications – SLKJCrane

Spider Crane Guide 2025: Types, Specs, Applications & Buying Tips In the last decade, spider cranes (mini spider

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice