Mastering Single Girder Overhead Crane Types Ultimate Guide to Choosing

Maximizing Limited Workshop Space? Smart Single Girder Crane Solutions Deliver

Struggling with these constraints?

➤ Low roof clearance restricting vertical space?

➤ Older factory structures with restrictive low bull’s legs?

➤ Roof-loading only workshops (no floor columns)?

➤ Hazardous environments where electric equipment is unsafe?

For lifting needs ≤32 tons, a customized single girder overhead crane is your ideal space-optimized solution. Its compact design conquers spatial limitations while offering unmatched adaptability for unique structures.

Targeted Solutions for Your Challenges:

| Your Challenge | Our Single Girder Solution | Key Benefit |

|---|---|---|

| Ultra-low roof position | Low-profile girder + underslung hoist | Gains 15-30cm vertical clearance |

| Low bull’s legs (legacy design) | Reinforced runway beams | Avoids structural modifications |

| Roof-only load-bearing | Wide-span bridge (6-28m) | Zero floor columns required |

| Non-electric environments | Pneumatic/manual hoist configurations | Explosion-proof & moisture-resistant operation |

Why Single Girder Wins in Tight Spaces:

✅ Vertical Space Optimization: Minimal headroom occupation with underslung designs.

✅ Legacy Building Adaptation: Distributes loads safely on low bull’s legs.

✅ Column-Free Support: Full reliance on roof structures.

✅ Hazard-Safe Operation: Air-powered options for volatile/damp areas.

✅ Cost Efficiency: 30% lighter than double girders → lower reinforcement costs.

Types of Single Girder Overhead Cranes

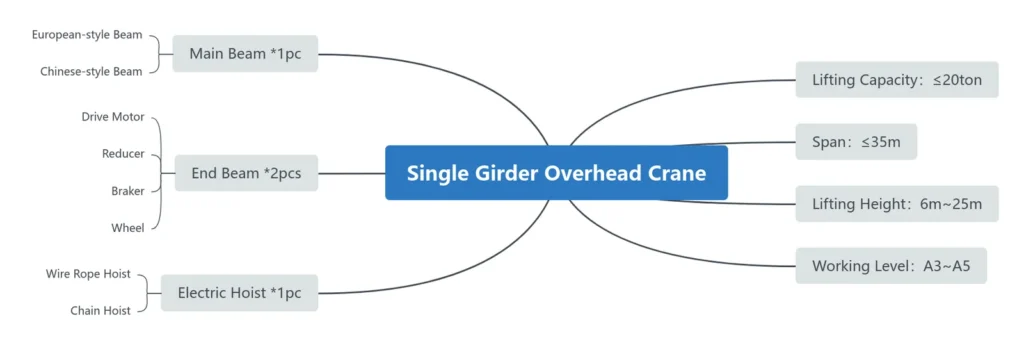

Demystifying the Single Girder Overhead Crane Design

At its core, the single girder overhead crane type features one primary load-bearing beam (the girder) that spans the width of your work area. This beam travels along elevated runway beams, typically mounted to the building structure or free-standing support columns. The hoist and trolley mechanism moves laterally beneath this single girder. This fundamental design is the key to its widespread popularity and distinct advantages.

Key Advantages Driving the Popularity of Single Girder Crane Systems:

-

Lower Initial Investment: Significantly reduced material and installation costs compared to double girder configurations. A single girder EOT crane often represents the most budget-conscious entry point into overhead lifting.

-

Reduced Headroom Requirement: The compact design, with the hoist operating under-hung beneath the girder, minimizes the required building height. This is invaluable in facilities with height constraints or when retrofitting existing structures.

-

Simpler Installation: Lighter components and a less complex structure translate to faster, often less disruptive installation times.

-

Lighter Weight: Places less stress on the building structure, potentially eliminating the need for expensive reinforcement in many cases.

-

Ideal for Moderate Duty & Span: Excels in applications with standard lifting capacities (typically up to 20 tons, though specialized designs go higher) and spans up to 30 meters. Perfect for workshops, assembly lines, storage areas, and maintenance bays.

Exploring the Major Single Girder Overhead Crane Types

Understanding the specific variations within the single girder crane category is essential for matching the right equipment to your operational needs.

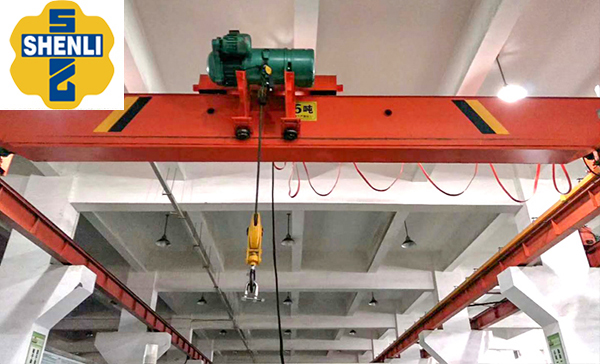

1. Top-Running Single Girder Overhead Crane (The Industry Standard)

-

How it Works: The crane’s main girder rides on top of runway beams fixed to building columns or dedicated support structures. The hoist trolley traverses along the bottom flange of this girder.

-

Key Features & Benefits:

-

Maximized Hook Height: Offers the greatest possible lift height beneath the crane runway, crucial for taller buildings or maximizing usable space.

-

Higher Capacities & Spans: Generally capable of handling higher capacities and longer spans than underhung types within the single girder class.

-

Robust Construction: Designed for reliable performance in demanding industrial environments.

-

-

Optimal Applications: Manufacturing plants, fabrication shops, warehouses with sufficient headroom, foundries, loading bays where maximizing lift height is critical. Ideal for single girder EOT crane needs requiring robust performance.

-

Long Tail Keyword Focus: Benefits of top-running single girder crane design for maximizing lift height.

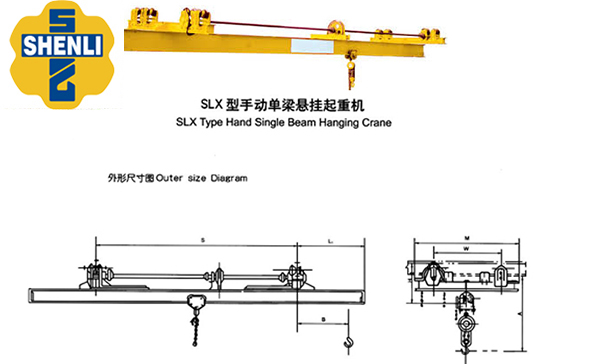

2. Underhung / Monorail Single Girder Crane Systems (Space Savers & Integration Specialists)

-

How it Works: The crane girder itself is suspended from the bottom flange of overhead runway beams. The hoist trolley also runs along the bottom flange of the main girder. This creates a truly integrated lifting system within the ceiling structure.

-

Key Features & Benefits:

-

Minimal Headroom Consumption: The most space-efficient single girder crane type, ideal for low-clearance buildings.

-

Building Structure Utilization: Runway beams are often directly attached to roof support structures (like roof trusses), distributing the load efficiently.

-

System Integration: Enables complex layouts with curves, switches, and multiple runways, creating sophisticated material flow paths (monorail systems). Excellent for modular overhead crane solutions.

-

-

Optimal Applications: Assembly lines (automotive, appliances), clean rooms, packaging facilities, areas with strict height limitations, applications requiring complex travel paths.

-

Long Tail Keyword Focus: Space-saving advantages of underhung monorail single girder crane systems.

3. Light-Duty Single Girder Workstation Cranes (Ergonomics & Precision)

-

How it Works: A specialized subset of underhung cranes, designed for very light capacities (typically under 2 tons). They feature lightweight aluminum or steel girders suspended from ceiling-mounted runways or freestanding support structures.

-

Key Features & Benefits:

-

Unparalleled Maneuverability: Extremely low push/pull forces allow operators to position loads with fingertip control, reducing fatigue.

-

Modular & Expandable: Systems can be easily reconfigured or expanded as workflow needs change.

-

Ergonomic Lifesaver: Dramatically reduces worker strain and injury risk associated with manual lifting or awkward positioning.

-

Precision Handling: Essential for delicate assembly tasks or positioning sensitive components.

-

-

Optimal Applications: Assembly workstations, quality inspection areas, machine tool loading/unloading, electronics manufacturing, laboratories, repair benches. The ultimate ergonomic material handling solution.

-

Long Tail Keyword Focus: Implementing ergonomic light-duty single girder workstation cranes for assembly precision.

-

4. Freestanding Single Girder Bridge Cranes (Building Independence)

-

How it Works: These single girder crane systems are supported by their own dedicated floor-mounted columns and runway system, completely independent of the building’s structure.

-

Key Features & Benefits:

-

No Building Load: Eliminates the need for structural analysis and potential reinforcement of existing buildings.

-

Outdoor/Canopy Use: Can be installed outdoors under canopies or in buildings with insufficient structural capacity.

-

Retrofit Flexibility: Ideal solution when adding a crane to an existing facility where attaching to the roof structure is impractical or too costly.

-

Portability (Potential): Some designs allow for relocation if facility layouts change significantly.

-

Optimal Applications: Brownfield sites, warehouses with lightweight roofs, outdoor storage yards (under cover), facilities undergoing phased upgrades, leased properties.

-

Long Tail Keyword Focus: Freestanding single girder crane solutions for buildings with structural limitations.

-

-

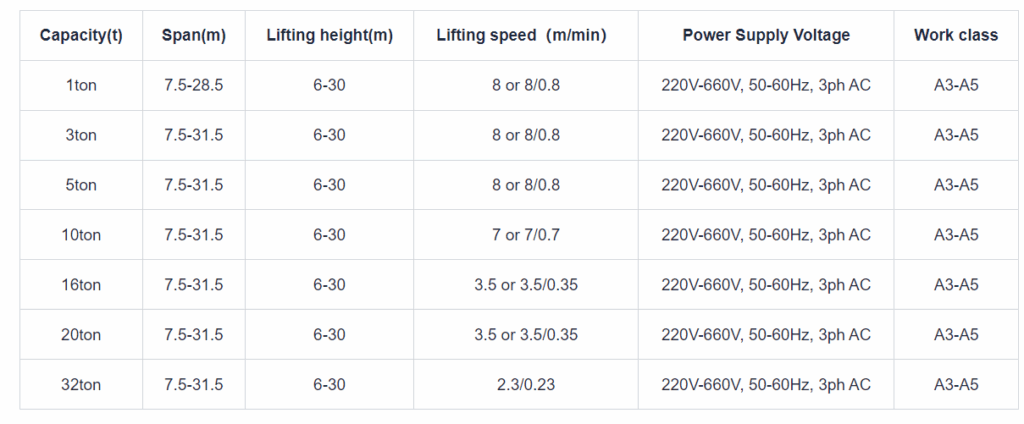

Critical Selection Factors Beyond the Single Girder Crane Type

Choosing the right single girder overhead crane type involves a thorough analysis of your specific operational parameters:

-

Capacity (Tonnage): Precisely determine the maximum weight you need to lift, including the weight of lifting attachments (slings, magnets, grabs). Always factor in a safety margin. Underestimating capacity leads to dangerous overloads and premature failure.

-

Span: The horizontal distance between the runway rails dictates the girder’s length and structural requirements. Accurate measurement is critical – longer spans require heavier girders and impact cost significantly.

-

Lift Height: Calculate the maximum distance the hook needs to travel from its highest possible position to its lowest required point (e.g., lifting off a truck bed and placing onto a tall rack). This directly impacts building height needs or achievable hook path.

-

Duty Cycle (Class): How intensively will the crane operate? Consider:

-

Light Service (Class A): Infrequent, low-intensity use (e.g., maintenance shops).

-

Moderate Service (Class B): Regular use at moderate speeds and loads (e.g., standard machine shops, warehouses).

-

Heavy Service (Class C/D): Frequent, near-continuous use at or near capacity (e.g., foundries, steel service centers). Selecting the correct duty class ensures longevity and safety. A single girder EOT crane designed for Class C will have robust motors, gearboxes, and braking systems compared to a Class A model.

-

-

Control Systems: Options range from basic pendant push-button stations (wired or radio-controlled) for localized operation to sophisticated cabin-operated controls for wide-span or complex cranes. Consider operator visibility and ergonomics. Radio remote controls offer significant flexibility and safety advantages.

-

Hoist Type: Chain hoists offer compactness and lower cost for lighter capacities. Wire rope hoists provide smoother operation, higher speeds, and greater durability for heavier or more frequent use. Choose the hoist technology that aligns with your capacity, duty cycle, and precision needs.

-

Environmental Conditions: Will the crane operate in extremes? Factors include:

-

Temperature: Foundries (high heat), cold storage (freezing).

-

Corrosives: Chemical plants, plating shops, marine environments.

-

Dust/Explosives: Grain elevators, paint booths, pharmaceutical clean rooms. Specialized components (sealed motors, corrosion-resistant coatings, stainless steel, explosion-proof ratings) are essential for harsh environments.

-

-

Safety & Compliance: Non-negotiable. Ensure the crane design and components meet or exceed all relevant local and international safety standards (CMAA, OSHA, FEM, AS, etc.). Key features include overload limit switches, emergency stop buttons, bumpers, runway end stops, and warning devices (lights/horns).

Innovations Shaping Modern Single Girder Crane Systems

The single girder overhead crane type is not stuck in the past. Cutting-edge technologies are enhancing performance, safety, and intelligence:

-

Intelligent Control Systems: Sophisticated variable frequency drives (VFDs) enable incredibly smooth acceleration, deceleration, and precise load positioning, minimizing load swing and reducing structural stress.

-

Remote Monitoring & Diagnostics (IoT): Sensors integrated into motors, gearboxes, and brakes provide real-time data on performance parameters (temperature, vibration, hours of operation). This enables predictive maintenance, preventing unexpected downtime by alerting technicians to potential issues before they cause failure. Imagine receiving an alert on your phone about a motor bearing showing abnormal heat signatures.

-

Anti-Sway Technology: Advanced algorithms actively control crane movement to automatically dampen load swing, significantly improving positioning accuracy and safety, especially when operated via radio remote.

-

Modular & Scalable Designs: Manufacturers increasingly offer standardized, pre-engineered components that simplify installation, reduce lead times, and make future modifications or expansions more cost-effective. This approach delivers customized efficiency without bespoke complexity.

Success Stories: Single Girder Crane Types in Action

Case Study 1: Automotive Tier 1 Supplier - Lean Manufacturing Boost

-

Challenge: Streamlining engine component assembly line, plagued by manual handling bottlenecks and ergonomic strain. Needed precise positioning without disrupting existing low-clearance conveyor infrastructure.

-

Solution: Implementation of a network of light-duty single girder workstation cranes (aluminum, 1-ton capacity) along key assembly stations. Integrated with ergonomic vacuum lifters.

-

Results:

-

35% reduction in component handling time.

-

Elimination of manual lifting injuries in targeted areas.

-

Enhanced assembly precision and quality control.

-

Seamless integration above existing conveyors due to low headroom design.

-

-

Quote: “The modular workstation cranes gave our operators fingertip control over heavy components. The ergonomic improvement was immediate, and the precision significantly reduced rework.” – Plant Operations Manager.

Case Study 2: Regional Distribution Center - Maximizing Cubic Storage

-

Challenge: Inefficient pallet movement in a high-bay warehouse with limited floor space. Needed to optimize vertical storage density without requiring costly building modifications.

-

Solution: Installation of top-running single girder EOT cranes (16-ton capacity, 25m span) equipped with radio remote controls and specialized pallet forks.

-

Results:

-

40% increase in vertical storage utilization.

-

Faster pallet put-away and retrieval times compared to previous forklift-only operation.

-

Reduced product damage from forklift collisions.

-

Lower operating costs (electricity vs. propane).

-

-

Quote: “The single girder cranes were the perfect fit. They gave us the height and reach we needed within our existing building shell, transforming our storage efficiency overnight.” – Warehouse Director.

Case Study 3: Precision Machining Workshop - Flexible Heavy Lifting

-

Challenge: Safely maneuvering large, expensive CNC machine tool components (beds, housings) within a constrained workshop space. Existing mobile cranes were cumbersome and floor space was precious.

-

Solution: A freestanding single girder bridge crane system (10-ton capacity, 18m span) with VFD controls for ultra-smooth movement and precise positioning.

-

Results:

-

Safe, controlled handling of critical components, eliminating drop risks.

-

Recovery of valuable floor space previously needed for mobile crane paths.

-

Significant reduction in machine setup/changeover times.

-

Enhanced workshop safety culture.

-

-

Quote: “The freestanding crane was a game-changer. It gave us the power and precision we needed right where we needed it, without touching the roof. Our machinists feel much safer handling these massive parts now.” – Shop Foreman.

Investing Wisely: Beyond the Initial Crane Price Tag

-

While the attractive upfront cost of a single girder overhead crane type is a major factor, true value is measured by Total Cost of Ownership (TCO):

-

Quality Components: Investing in reputable hoists (SHENLI,Columbus McKinnon, Kito, Demag), robust electrical gear (Siemens, Schneider, ABB), and high-grade structural steel pays dividends in longevity, reliability, and reduced maintenance. Cutting corners here leads to frequent breakdowns and safety risks.

-

Professional Installation & Commissioning: Improper installation is a leading cause of premature wear, safety hazards, and voided warranties. Always use certified crane installation specialists.

-

Preventive Maintenance Program: Regular, scheduled inspections and maintenance (lubrication, wear checks, electrical testing, safety device verification) are far cheaper than major repairs or unplanned downtime. Partner with a reliable service provider. Proactive maintenance is the single biggest factor in maximizing crane lifespan and minimizing TCO.

-

Operator Training: Well-trained operators use the crane efficiently, reduce accidental damage, and operate safely. This is a critical, often overlooked, investment.

-

Conclusion: Powering Your Productivity with the Right Single Girder Solution

The single girder overhead crane type remains an indispensable, versatile, and cost-effective cornerstone of modern industrial material handling. From the space-saving efficiency of underhung monorails to the robust performance of top-running EOT cranes and the ergonomic finesse of workstation systems, there’s a single girder solution optimized for nearly every lifting challenge.

Choosing the ideal single girder crane type requires careful consideration of your specific capacity, span, lift height, duty cycle, environment, and operational goals. By understanding the distinct advantages and applications of each variation, leveraging modern innovations, learning from proven success stories, and focusing on Total Cost of Ownership, you can make an investment that delivers significant returns in productivity, safety, and operational efficiency for years to come.

Ready to Transform Your Material Handling?

Don’t leave your lifting efficiency to chance. Contact our expert engineering team today for a FREE, no-obligation consultation and site assessment. We’ll analyze your specific requirements and recommend the optimal single girder overhead crane type solution tailored to maximize your ROI, enhance safety, and streamline your workflow. Visit our website or call us now to schedule your assessment and request a detailed quote. Let’s engineer your lifting success together.

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice

Mastering Single Girder Overhead Crane Types & Prices

The roof position of my factory workshop is low, which single girder overhead crane solution can make full use of the limited upper and lower space?

My factory building is relatively old and the bull’s leg position is designed to be low, which single girder overhead crane solution can maximize the use of the existing space?

My workshop has no load-bearing columns, but the roof is load-bearing, which single girder overhead crane solution is suitable?

What kind of single girder overhead crane solution is available for the working environment which is not suitable for electric equipment?

……

Whether you are in the procurement plan in progress, or are determining the customized scheme of plant lifting equipment, if the lifting capacity requirement is 20ton and below, single girder overhead travelling crane with the advantages of simple structure, flexible scheme and easy dismantling and transportation can be your second choice. And how to choose the right customized program according to your plant is crucial, the following will be from the type of single girder overhead crane, parameter information and price, etc., so that you have a comprehensive understanding of the single girder overhead crane and choose a more suitable program for you.