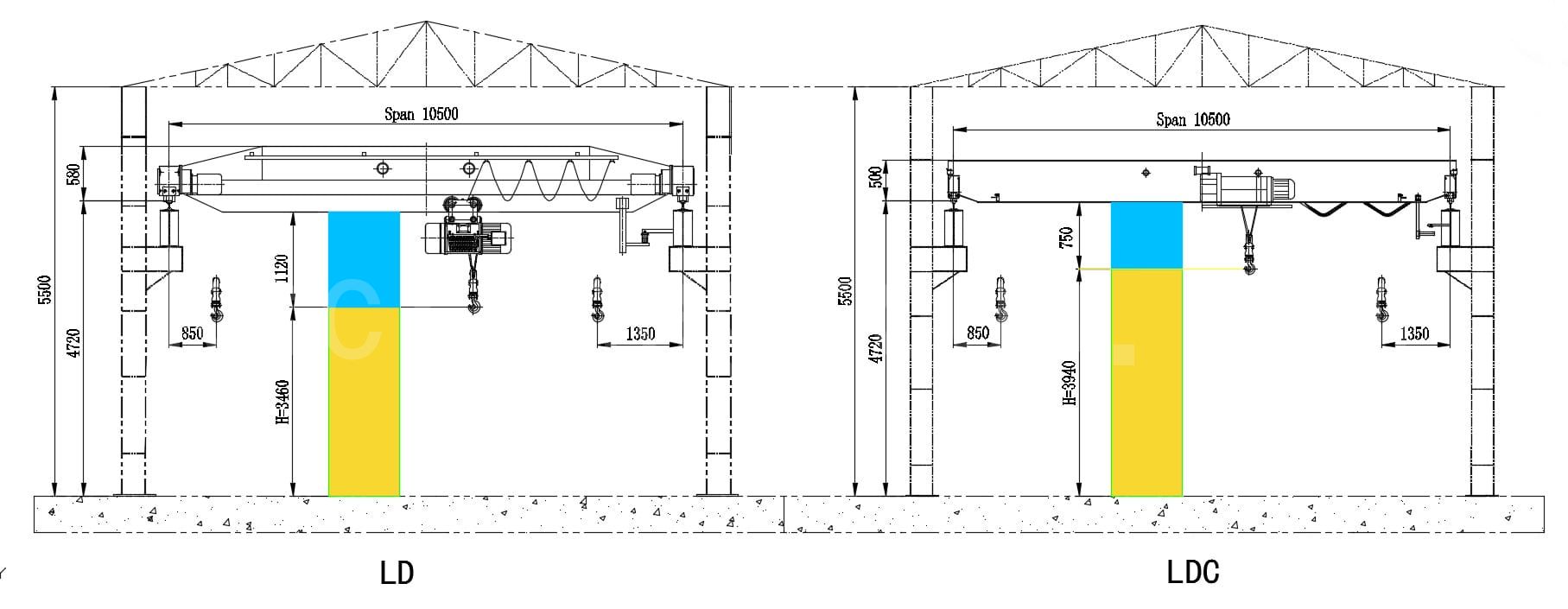

LD Ordinary vs. LDC Low Headroom Single Girder Overhead Crane: Best Choice for Factory Renovation

Introduction

Upgrading or renovating a factory workshop often brings one major challenge: how to choose the right overhead crane when ceiling height and structure are limited.

In older factories, the available headroom is often insufficient for standard cranes, making the choice between an LD Ordinary Single Girder Overhead Crane and an LDC Low Headroom Single Girder Overhead Crane extremely important.

This article provides a detailed comparison of structure, parameters, application scenarios, and real renovation cases, helping you select the most cost-effective solution for factory upgrading.

Crane Structures & Technical Parameters

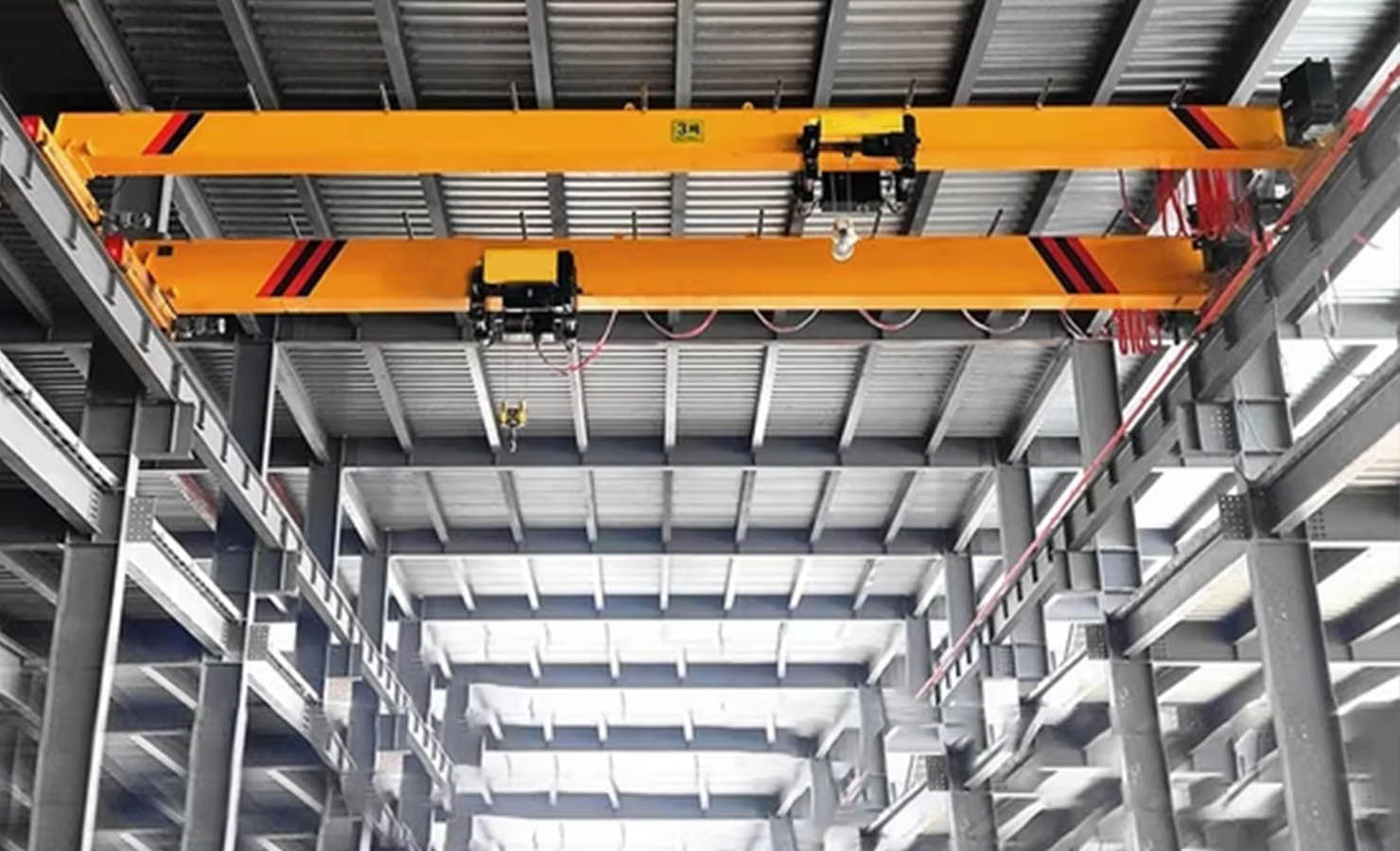

1. LD Ordinary Single Girder Overhead Crane

-

Design Characteristics:

-

Standard single girder structure

-

Electric hoist operates below the girder

-

Simple installation, widely used for general lifting

-

-

Typical Parameters:

-

Load Capacity: 1–20 tons

-

Span: 7.5–31.5 meters

-

Lifting Height: 6/9/12 meters

-

Working Class: M3

-

Control Options: Pendant control, optional remote control

-

-

Advantages:

-

Mature design, economical initial cost

-

Easy spare parts supply and maintenance

-

Best for new workshops with sufficient roof clearance

-

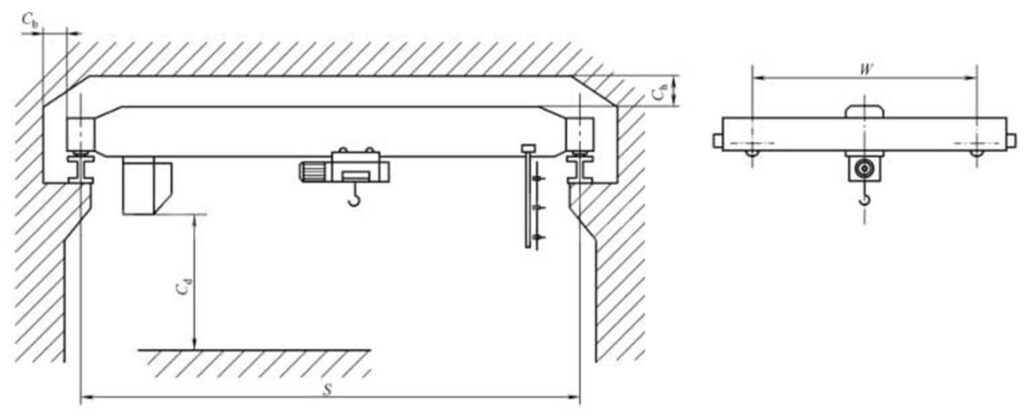

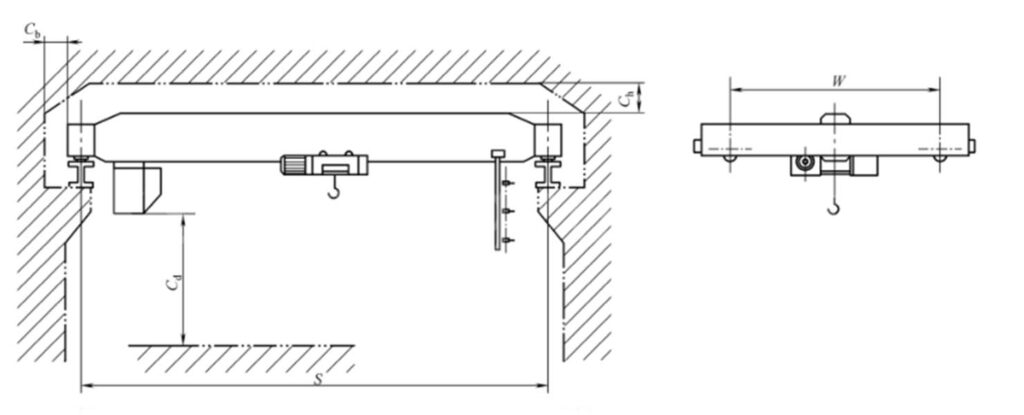

2. LDC Low-Headroom Single Girder Overhead Crane

-

Design Characteristics:

-

Compact hoist design, mounted close to the girder

-

Increases effective lifting height by 300–1500 mm compared with LD type

-

Specially designed for low ceiling or renovation projects

-

-

Typical Parameters:

-

Load Capacity: 1–20 tons

-

Span: 7.5–31.5 meters

-

Lifting Height: 6/9/12/15 meters

-

Working Class: M3

-

Control Options: Remote control or cabin control

-

-

Advantages:

-

Maximum utilization of workshop headroom

-

Saves civil engineering cost (no need to raise roof)

-

Perfect for factory renovation and workshops with limited height

-

Practical Renovation Cases

Case 1: Steel Fabrication Plant – 10 Ton Crane Replacement

-

Situation:

Old workshop, ceiling height only 8 meters, using a 10-ton LD crane. Effective hook stroke was limited. -

Solution:

Upgraded to 10-ton LDC Low-Headroom Crane, gaining +650 mm lifting height. -

Result:

-

Increased steel plate handling efficiency by 20%

-

Saved approx. $60,000 in building modification costs

-

Case 2: Machinery Workshop – New 5 Ton Installation

-

Situation:

Plant height 7.5 m, required crane for machining center maintenance. -

Solution:

Installed 5-ton LDC crane instead of LD type, achieving better hook clearance,The effective lifting height is increased by 400mm. -

Result:

-

Lifting stroke increased by 35%

-

Reduced downtime, ROI achieved in 10 months

-

Case 3: Textile Factory – 2 Ton Renovation

-

Situation:

Low ceiling workshop, many pipelines blocking space. -

Solution:

Installed 2-ton LDC crane, avoiding relocation of pipelines. -

Result:

-

30% higher lifting efficiency

-

Renovation downtime cut by 50% (25 days)

-

Comparison Chart

| Feature / Type | LD Ordinary Crane | LDC Low-Headroom Crane |

|---|---|---|

| Load Capacity | 1–20 tons | 1–20 tons |

| Span | 7.5–28.5 m | 7.5–22.5 m |

| Effective Hook Height | Limited by hoist below girder | Increase height +300–1500 mm clearance |

| Installation Cost | Lower crane cost, higher civil work | Slightly higher crane cost, no roof lifting |

| Ideal Application | New factories, high clearance | Renovation, low ceiling workshops |

| Return on Investment | May require roof modification | Quicker ROI, avoids major construction |

Conclusion

For new factories with enough roof clearance, the LD Ordinary Single Girder Overhead Crane remains a cost-effective choice.

However, for renovation, upgrading, or low-roof workshops, the LDC Low Headroom Crane is the smarter investment, offering:

Higher lifting stroke in limited space

Significant savings on civil construction

Faster return on investment

👉 When planning factory renovation, always evaluate headroom, load capacity, budget, and long-term expansion. Choosing the right crane not only saves cost but also improves operational efficiency.

Contact Engineer SLKJCrane. We offer you the best solutions and suggestions for the upgrading and transformation of your factory for free

Frequently Asked Questions (FAQ) About Gantry Cranes

An LD ordinary single girder crane uses a standard hoist running below the girder, while an LDC low-headroom crane uses a compact hoist design that increases effective lifting height by 300–1500 mm.

The LDC low-headroom single girder crane is more suitable for renovation projects, as it saves space and avoids costly roof modifications, especially in old workshops with limited clearance.

-

LD ordinary cranes: 1–20 tons

-

LDC low-headroom cranes: 1–20 tons

Both can be customized according to span, lifting height, and working class requirements.

In many renovation projects, using an LDC low-headroom crane avoids roof lifting or building reinforcement, which can save $20,000–$80,000 in civil engineering costs.

Yes. Both LD and LDC cranes support pendant control and wireless remote control. LDC type is more commonly equipped with remote operation due to its use in compact or crowded workshops.

Cranes as the Backbone of Modern Steel Plants

Cranes as the Backbone of Modern Steel Plants How the Right Steel Plant Crane Solutions Drive Efficiency, Safety,

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios When people ask me about spider

How To Choose The Right Spider Crane

How To Choose The Right Spider Crane (Mini Crawler Crane) for a Project – My Practical Experience When

Low Headroom Wire Rope Hoist for Tight Workshops | SLKJCrane

Cost Saving Low Headroom Wire Rope Hoist for Tight Workshops When I visit customers’ workshops and warehouses, I

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice