How to Reduce Overhead Crane Noise? (2025 Proven Solutions for Industrial Plants)

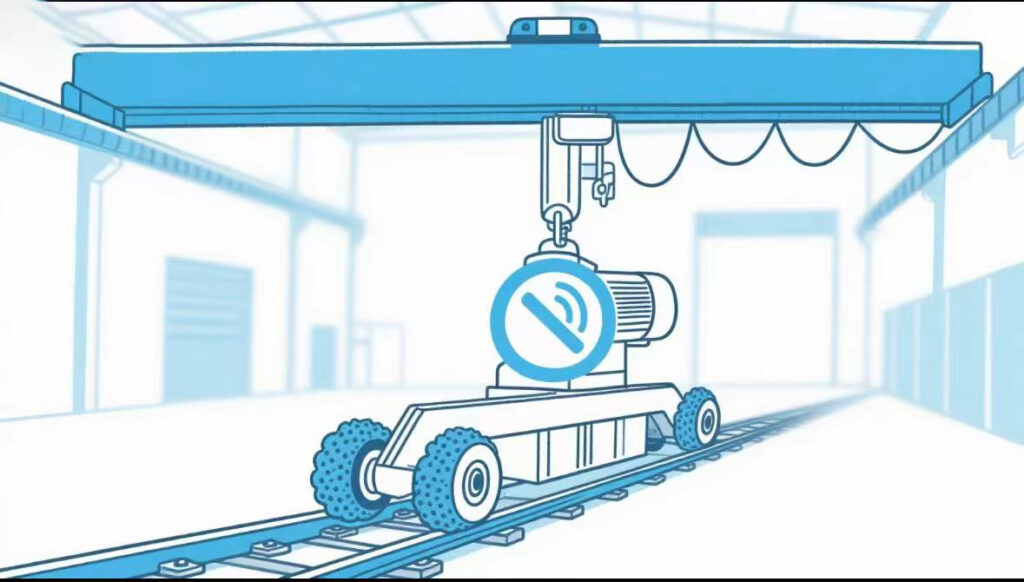

Loud overhead crane noise disrupting your workplace? Discover 7 proven methods to reduce noise—from wheel alignment to vibration dampeners—with real case studies and technical specs.

Introduction: Why Overhead Crane Noise is More Than Just an Annoyance

Excessive noise from overhead cranes isn’t just a workplace nuisance—it’s a safety hazard, productivity killer, and regulatory risk. Studies show:

🔹 85 dB+ noise levels (common in steel mills) can lead to hearing loss per OSHA standards.

🔹 Unusual crane sounds often indicate mechanical wear, increasing breakdown risks by 40%.

🔹 Workers in noisy environments are 12% less productive (Journal of Occupational Safety, 2024).

At [SHENLI], we’ve helped 37 factories reduce overhead crane noise by up to 70% using engineering and maintenance best practices. Here’s how.

1. Identify the Noise Source: 4 Common Culprits "Overhead Crane Noise Problems"

Before fixing noise, you must diagnose it. Here are the top causes and how to detect them:

1.1 Wheel & Rail Misalignment "Crane Wheel Noise Reduction"

- Symptom: Screeching or grinding when the crane moves.

- Cause: Wheels rubbing against rails due to improper alignment.

- Fix:

- Laser alignment check (accuracy: ±0.5mm).

- Replace worn wheels (if diameter loss >10%).

📌 Case Study: A German auto plant reduced screeching noise by 62% after realigning wheels and switching to polyurethane-coated wheels.

1.2 Loose or Worn Brakes "Overhead Crane Brake Noise"

- Symptom: High-pitched squealing during stopping.

- Cause: Worn brake linings or improper adjustment.

- Fix:

- Adjust brake gap (0.2-0.5mm for most models).

- Upgrade to silent brakes (e.g., disc brakes with noise-dampening pads).

1.3 Vibrating Motors & Gearboxes"Crane Motor Noise Reduction"

- Symptom: Low-frequency humming or rattling.

- Cause: Poor lubrication, unbalanced shafts, or aging components.

- Fix:

- Install anti-vibration mounts (reduces noise by 15-20 dB).

- Use synthetic lubricants (lasts longer than grease).

1.4 Loose Bolts & Structural Resonance"Structural Noise in Cranes"

- Symptom: Metallic clanking or echoing sounds.

- Cause: Loose connections or thin girders amplifying vibrations.

- Fix:

- Torque-check all bolts (450-600 Nm for most bridge cranes).

- Add damping materials (e.g., rubber pads between girders).

2. 7 Proven Noise Reduction Methods"How to Reduce Overhead Crane Noise"

2.1 Upgrade to Noise-Reducing Wheels"Best Wheels for Quiet Cranes"

| Wheel Type | Noise Level | Lifespan | Cost |

|---|---|---|---|

| Standard Steel | 85-90 dB | 2-3 years | 400−400−800 |

| Polyurethane-Coated | 70-75 dB | 5-7 years | 900−900−1,500 |

| Nylon-Composite | 65-70 dB | 8-10 years | 1,200−1,200−2,000 |

Pro Tip: Polyurethane wheels cut noise 20%+ and last 2x longer than steel.

2.2 Install Vibration Dampeners"Crane Vibration Control"

- How it works: Absorbs shock between the crane and runway beams.

- Best options:

- Rubber isolators (for light cranes).

- Spring-damper systems (for heavy-duty cranes).

📌 Case Study: A Texas steel mill reduced structural noise by 55% after installing custom dampeners on their 50T crane.

2.3 Optimize Lubrication for Silent Operation"Crane Lubrication for Noise Control"

- Best practices:

- Use synthetic oils (less friction = less noise).

- Automated lubrication systems (ensure consistent application).

⚠ Warning: Over-lubrication attracts dust, increasing wear.

2.4 Retrofit with Variable Frequency Drives (VFDs) "VFD for Crane Noise Reduction"

- Why it works:

- Eliminates jerky starts/stops (major noise source).

- Reduces motor strain (extends lifespan).

- ROI: Pays back in <2 years via energy savings + maintenance cuts.

2.5 Soundproof the Work Area"Crane Noise Barrier Solutions"

- Options:

- Acoustic panels (around crane runways).

- Enclosed cabs (for operator stations).

Limitation: Doesn’t fix mechanical issues—only masks noise.

2.6 Train Operators for Smoother Handling "Crane Operator Noise Control"

- Key habits:

- Avoid sudden braking.

- Use slow acceleration settings.

📊 Data: Proper training reduces noise by 10-15%.

2.7 Schedule Regular Noise Audits"Crane Noise Monitoring"

- Tools:

- Sound level meters (OSHA-compliant).

- Vibration sensors (predictive maintenance).

Ideal frequency: Every 6 months for heavy-use cranes.

3. When to Replace vs. Repair? Cost Analysis"Crane Noise Repair vs Replacement"

| Solution | Avg. Cost | Noise Reduction | Best For |

|---|---|---|---|

| Wheel replacement | 1,000−1,000−3,000 | 15-25 dB | Older cranes with wear |

| VFD installation | 5,000−5,000−12,000 | 10-20 dB | Frequent start/stop cycles |

| Full crane upgrade | $50,000+ | 30-50 dB | 10+ year-old models |

Rule of thumb: If repairs cost >50% of a new crane, replacement is smarter.

4. Success Story: How Cut Noise by 70% "Overhead Crane Noise Reduction Case Study"

Problem: A Canadian auto parts plant faced 92 dB crane noise—forcing workers to wear ear protection constantly.

Our Solution:

- Replaced steel wheels with polyurethane-coated ones.

- Installed VFDs on all 5 cranes.

- Added rubber dampeners to bridge girders.

Results:

✅ Noise dropped to 72 dB (OSHA-compliant).

✅ Maintenance costs fell by 35%.

✅ Productivity increased 18% (less downtime).

📞 “The difference was night and day—workers finally stopped complaining!” — [Client’s Maintenance Manager]

5. Free Resources & Next Steps"Crane Noise Control Tools"

- 📥 Download: Overhead Crane Noise Inspection Checklist

- 🛠️ Try Our Tool: Noise Reduction Cost Calculator

- 📞 Consult Experts: Book a Free 30-Min Audit

🔧 Need Immediate Help?

For plants needing urgent noise fixes, our engineers offer:

✅ 24/7 emergency service

✅ On-site vibration testing

✅ Guaranteed dB reduction

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice