How to Effectively Maintain and Care for Your EOT Crane: Expert Advice from Leading Manufacturers

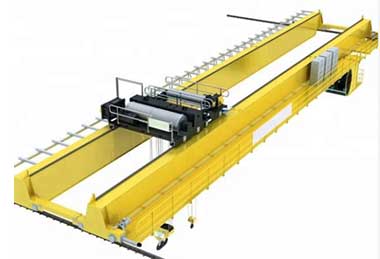

In modern industrial environments, EOT (Electric Overhead Traveling) cranes are widely used for various heavy lifting and transportation tasks. However, many businesses often overlook the importance of maintenance and care once they have chosen and deployed their EOT cranes. Good maintenance not only extends the lifespan of the equipment but also significantly enhances operational efficiency while minimizing the risk of accidents. As a dedicated EOT Crane manufacturer, SLKJ Crane (www.slkjcrane.com) is here to provide you with comprehensive maintenance and care guidelines to help you maximize the potential of your EOT cranes.

Basic Parameters of EOT Cranes

Before discussing maintenance strategies, it’s crucial to understand the basic parameters of EOT cranes. Typical configurations include:

- Load Capacity: Usually ranges from 1 ton to 20 tons, depending on the specific model.

- Span: Generally from 5 meters to 20 meters, suitable for different working environments.

- Lifting Height: Varies from 3 meters to 30 meters based on industrial needs.

- Drive System: Commonly includes electric motor drives and hydraulic drives.

Understanding these basic parameters will help you conduct targeted inspections and maintenance in the subsequent sections.

The Necessity of Maintenance and Care

As with all machinery, EOT cranes experience wear and tear over time. Without proper maintenance, equipment failures, work interruptions, and even safety accidents may occur. This not only affects productivity but also results in unnecessary financial losses for the business. Therefore, regular maintenance and care are critical to ensuring the normal operation of your EOT crane.

Maintenance and Care Tips for EOT Cranes

1.Regular Inspections and Cleaning

- Periodically inspect all components of the EOT crane, including electrical, mechanical, and hydraulic systems. Special attention should be given to critical components such as cables, braking systems, and hooks.

- Clear debris from the crane tracks regularly to ensure smooth operation and prevent obstructions during lifting tasks.

2.Lubrication System

- Conduct regular lubrication of all moving parts of the EOT crane. Using lubricants effectively reduces friction and extends the longevity of the equipment.

- Be sure to use the lubricants recommended by the manufacturer to ensure optimal lubrication performance.

3.Electrical System Maintenance

- Regularly check the electric motor and control systems to ensure that electrical connections are not overheating or damaged. Replace aging cables promptly to avoid potential short circuit and fire hazards.

- Inspect sensors and control panels to ensure they are functioning properly, preventing accidental operational errors.

4.Safety Equipment Testing

- Periodically conduct functional tests on the EOT crane’s safety equipment, including anti-falling systems and overload protection devices, ensuring they operate correctly in critical moments.

- Provide comprehensive safety training to improve operators’ safety awareness and operational skills.

5.Fault Recording and Analysis

- After each maintenance session, document inspection results and any issues discovered to facilitate future maintenance planning.

- If faults occur, conduct timely analysis and repairs to prevent small problems from accumulating into larger hazards.

Emerging Market Powerhouses: Cost-Effective Innovation

Weihua Group: 5G-Enabled Smart Crane Revolution

Weihua’s i-SteelCloud platform enables millimeter-precision remote control via 5G networks. At Ningbo-Zhoushan Port, their AI-powered tandem lifting system increased container throughput by 17,000 TEUs/month.

SLK Intelligent Solutions: Customized Integration Excellence

At slkjcrane’, we bridge premium technology with localized support – providing turnkey crane integration with ROI-focused customization:

Dual-Crane Synchronization Systems eliminating alignment errors

Regenerative Power Units capturing 35% of descent energy

Modular Structural Upgrades extending service life by 15+ years

*Success Story: A Vietnamese EV battery plant saved $2.1 million annually after implementing our hybrid Konecranes/SLK solution featuring proprietary motion control algorithms.*

Professional Services from SLKJ Crane

As a leading EOT Crane manufacturer in the industry, SLKJ Crane not only provides high-quality equipment but also serves as your long-term partner for maintenance and care. We offer professional maintenance services and spare parts support to keep your EOT cranes in optimal working condition. Our technical team will tailor personalized maintenance plans based on your specific needs to ensure efficient and safe operation.

Conclusion

Maintaining and caring for your EOT crane is essential for keeping it running efficiently and prolonging its lifespan. By regularly conducting inspections, lubrication, cleaning, and electrical maintenance, you can significantly reduce equipment failure rates and improve productivity. As your trusted EOT Crane manufacturer, SLKJ Crane is always here to provide you with quality services and support. If you have any questions or needs regarding EOT cranes, feel free to visit our website www.slkjcrane.com or contact our professional service team—we are dedicated to providing you with answers and support.

We believe that professional and timely service is key to enhancing customer satisfaction. We hope the maintenance tips provided above will help safeguard your EOT crane, allowing you to stand out in the competitive industry! For further assistance or inquiries, please don’t hesitate to reach out to us.

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice