How to Choose the Right Crane Type

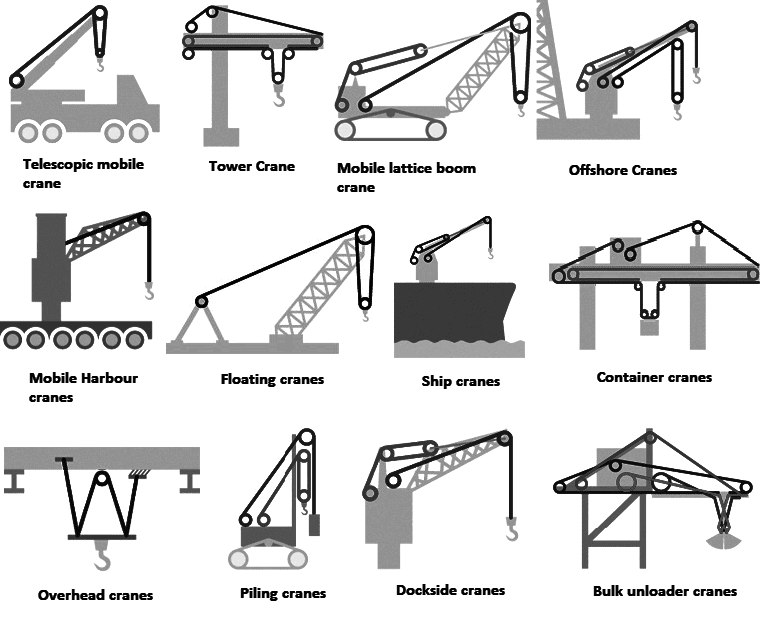

Selecting the appropriate crane type is critical for optimizing efficiency, safety, and cost-effectiveness in construction, manufacturing, or logistics projects. Below is a concise guide tailored to different operational needs and scenarios:

1. Assess Project Requirements

Load Capacity & Lifting Height

For heavy-duty tasks like steel beam installation in high-rise construction, tower cranes excel with their extended lifting heights (up to 248 meters) and capacities exceeding 200 tons18. Conversely, smaller-scale material handling may favor electric hoists or jib cranes with compact designs

Mobility Needs

Projects requiring frequent relocation (e.g., urban construction) benefit from mobile cranes like hydraulic truck-mounted cranes. For unstable or soft terrain, crawler cranes provide superior stability

2. Evaluate Site Conditions

Space Constraints

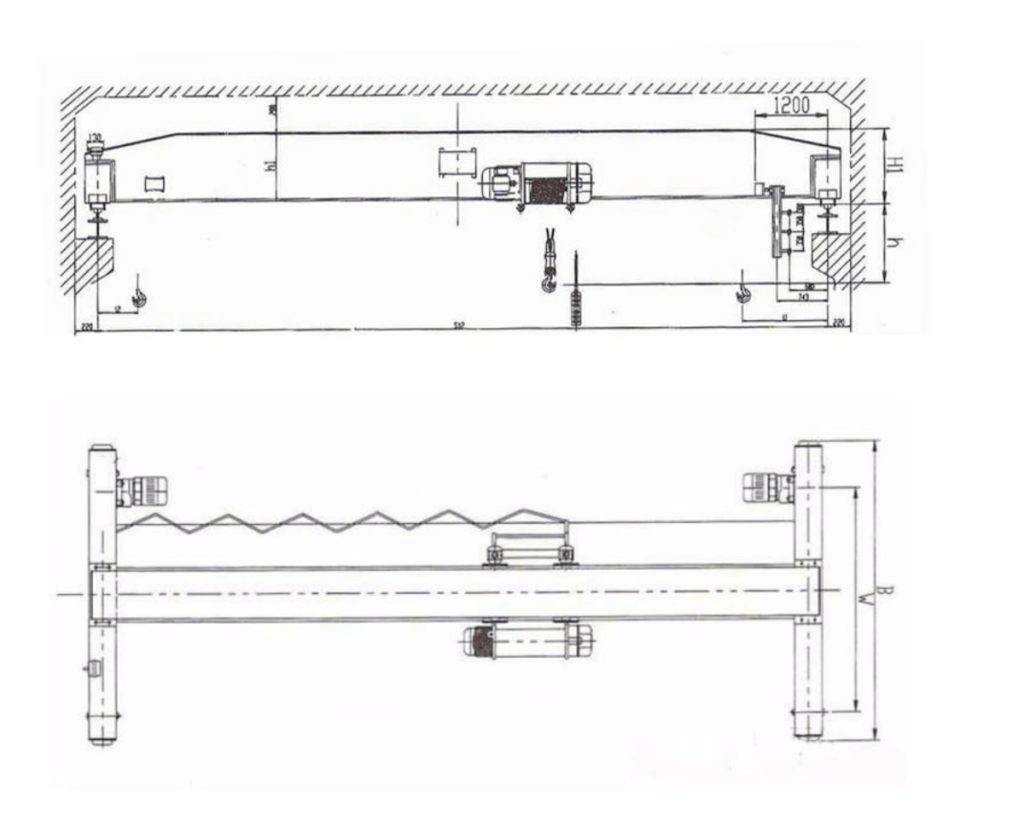

In confined spaces (e.g., warehouses), overhead traveling cranes or low headroom cranes maximize vertical space utilization without compromising load capacity

Ground Stability

Sites with uneven surfaces demand crawler cranes, while tire cranes suit paved areas where ground preservation is essential

3. Prioritize Operational Flexibility

- Multi-Purpose Applications

Hybrid solutions like self-erecting tower cranes combine installation speed with high-load performance, ideal for mixed-use construction projects. - Specialized Tasks

For wind turbine assembly or shipbuilding, luffing jib cranes or gantry cranes offer precision in restricted operational zones

4. Consider Cost & Efficiency

- Budget Constraints

Truck-mounted cranes reduce initial investment for sporadic use, while long-term projects justify tower cranes for sustained productivity. - Energy Efficiency

Opt for electric or hybrid models (e.g., EOT cranes) to align with sustainability goals and reduce operational costs

5. Safety & Compliance

- Always verify load charts and ensure compliance with ISO 10972-5 standards for structural integrity.

- Routine checks on critical components (e.g., Rotex gears, outriggers) prevent accidents caused by mechanical failures

Example Scenarios

| Scenario | Recommended Crane | Key Advantage |

|---|---|---|

| Urban high-rise construction | Self-climbing tower crane | Modular assembly, minimal footprint |

| Port logistics | Rubber-tired gantry crane | High-speed container handling |

| Wind farm installation | Crawler crane with luffing jib | Stability on uneven terrain |

By aligning crane specifications with project demands and environmental constraints, businesses can achieve optimal operational outcomes while mitigating risks. For specialized applications, consulting manufacturers SHENLI Crane ensures access to tailored solutions

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice