Optimizing Your Choice of Single Overhead Crane for Low Headroom Workshops

When it comes to selecting a single overhead crane, particularly in workshops with limited headroom, there are several crucial factors to consider. This comprehensive guide provides insights into navigating these constraints while ensuring safe and efficient materials handling.

Types of Single Girder Overhead Cranes

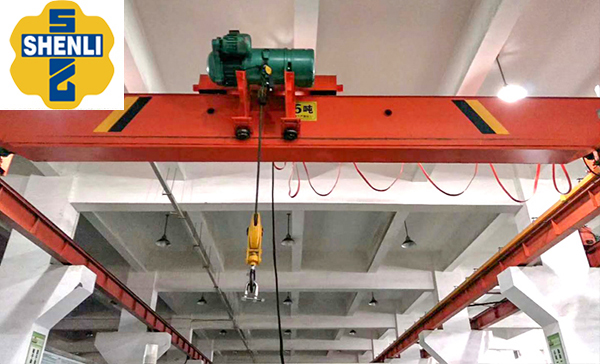

Single Girder Overhead Cranes

The single girder overhead crane is a versatile material handling solution commonly used in warehouses, workshops, and manufacturing facilities. It features a single main beam that supports the lifting mechanism, which typically includes an electric hoist or a manual hoist. This design allows for efficient operation in spaces with lower headroom, making it ideal for environments with height restrictions.

Explosion Proof Overhead Crane

The double girder overhead crane is a widely used material handling equipment in industrial and warehouse settings. It consists of two parallel main beams, providing greater structural strength and higher lifting capacity. Compared to single girder cranes, double girder cranes can bear heavier loads, making them suitable for environments where frequent and efficient movement of heavy items is required.

Underslung Girder Overhead Crane

The underslung girder overhead crane is a specialized type of crane that is designed to be mounted from the underside of a structural support, such as a roof or overhead beam. This design allows for an efficient use of vertical space, making it particularly advantageous in facilities with height limitations or where ground-level clearance is crucial.

FEM Standard Overhead Crane

FEM (Fédération Européenne de la Manutention) standard overhead cranes are specifically designed to meet the rigorous criteria outlined by the European materials handling industry. These standards focus on safety, efficiency, and durability, ensuring that the cranes operate effectively in diverse industrial environments, from manufacturing plants to logistics centers.

Low Headroom Girder Overhead Crane

A Low Headroom Girder Overhead Crane is specifically designed for environments where space is at a premium, particularly in facilities with low vertical clearance. This specialized crane type maximizes lifting height while minimizing the overall height of the crane system, making it an ideal choice for warehouses, manufacturing plants, and other industrial settings.

Understanding Your Workshop’s Clear Height

Measuring the Clear Height

The first step in selecting a single girder overhead crane is to accurately measure the workshop’s clear height. This measurement involves determining the distance from the floor to the lowest point of the ceiling, including any obstructions that may reduce available headroom.

- Importance of Accurate Measurement: Knowing the exact clear height helps in selecting a crane that fits appropriately within your workspace, reducing the risk of operational hazards.

Identifying Constraints and Limitations

In addition to measuring clear height, it’s essential to identify any other spatial constraints within the workshop. This includes reviewing existing installations, lighting fixtures, and ventilation systems, which may affect the crane’s positioning and operation.

Benefits of Low Headroom Cranes

Features of Low Headroom Design

Opting for a low headroom design in a single overhead crane allows for more efficient use of limited vertical space. These cranes are engineered to minimize the gap between the crane’s components and the workshop ceiling, enabling maximum lifting height.

- Enhanced Lifting Capacity: Low headroom cranes provide better lift heights as they are designed to operate closer to the ceiling, creating more usable vertical space for lifting and maneuvering loads.

Common Models of Low Headroom Cranes

Various low headroom crane models are available, each serving different operational needs. Here are some examples:

-

Pillar Mounted Single Girder Crane: Ideal for workshops where space is limited, this design allows the crane to operate effectively in tight areas.

-

Wall-Mounted Single Girder Crane: This model is excellent for utilizing side wall spaces and is suitable for workshops with restricted headroom.

-

Electric Wire Rope Hoist Crane: Provides efficient lifting capabilities while also minimizing vertical space requirements.

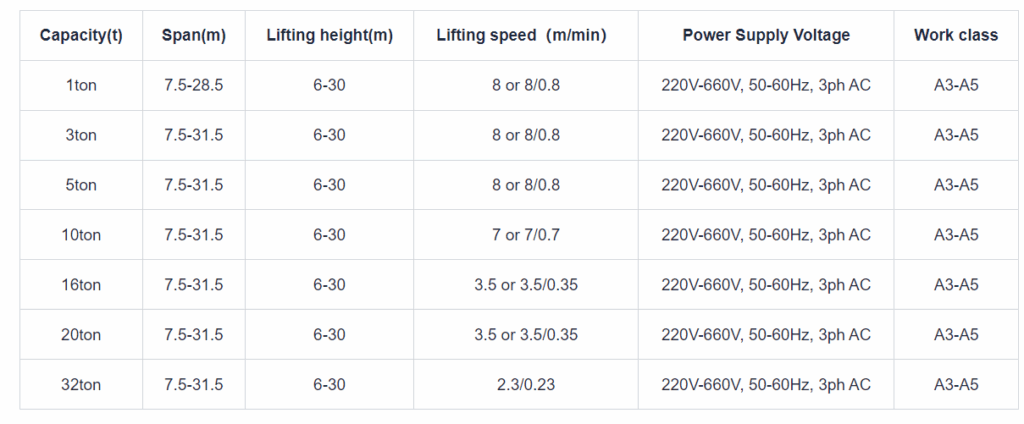

Specifications Table for Common Models

| Model | Span (m) | Lifting Capacity (t) | Lift Height (m) | Headroom Required (m) |

|---|---|---|---|---|

| Low Headroom Single Girder Crane | 5-30 | 1-20 | 3-10 | 2.5-3.5 |

| Electric Hoist Single Girder | 5-25 | 0.5-10 | 3-8 | 2.2-3.0 |

| Wall-Mounted Single Girder | 4-15 | 1-5 | 2-5 | 2.0-3.0 |

Optimizing Lift Height based on Application Needs

Factors Influencing Lift Height Decisions

When selecting the lift height for a single overhead crane, consider the types of loads you’ll be handling and the frequency of their movement. An optimized lift height ensures safe and efficient handling without compromising space.

-

Avoiding Excessive Heights: While it may seem beneficial to choose a higher lift height, it can lead to wasted space, especially if it surpasses the operational needs.

-

Addressing Low Heights: On the other hand, insufficient lift height may severely limit operational capacity, especially when dealing with taller loads.

Custom Solutions for Unique Requirements

When Off the Shelf Doesn't Fit

In cases where standard single overhead cranes do not meet operational demands, considering customized solutions is advisable. Customization may involve adjusting dimensions, materials, or even integrating specific functionalities.

- Tailored Design Features: Custom cranes can be designed to fit specific work environments, allow for better space utilization, or accommodate specialized equipment.

Consultation and Professional Guidance

Working with experienced professionals like SLKJ Crane (www.slkjcrane.com) offers invaluable support in planning and implementing custom solutions. Our consultants can work with you to understand your specific needs and offer design modifications that best fit your workshop environment.

Recommended Models Based on Common Customer Needs

Options for Different Industries

Different industries have varying requirements for single overhead cranes. Here are a few recommendations based on common industry applications:

-

Manufacturing Plants: A low headroom single girder crane with an electric hoist is ideal for metal and fabricating shops where materials are heavy and require frequent lifting.

-

Warehouse Operations: Wall-mounted designs can optimize space in warehouses, allowing for precise load handling without taking up ground space.

-

Construction Sites: Customized cranes with enhanced lifting capacities and mobility options can serve efficiently in dynamic construction environments.

Professional Services and Support from SLKJ Crane

At SLKJ Crane, we pride ourselves on our high-quality offerings and professional services that extend beyond just selling a product.

Comprehensive Post Purchase Support

Our commitment to customer satisfaction includes:

-

Investment in Customer Success: Our goal is to assist you in maximizing your productivity by providing ongoing support, updates, and insights for your crane systems.

-

Flexible Financing Options: We offer financing solutions to help make purchasing a single overhead crane more feasible for businesses of any size.

Operational Training and Safety Programs

An essential aspect of operating an overhead crane successfully is ensuring your team is well-trained in its use:

-

On-Site Training Sessions: We provide comprehensive training programs to ensure all operational staff are familiar with crane operation, safety protocols, and best practices.

-

Safety Assessments: Our experts can perform safety assessments of your facility to identify risks and suggest necessary measures, reinforcing your investment’s safety and efficacy.

Conclusion: Making an Informed Choice

When faced with constraints in headroom, selecting the right single overhead crane can significantly enhance operational efficiency and safety. A thorough understanding of your space, along with consideration for low headroom designs and potential custom solutions, empowers you to make the best choice for your specific needs.

For those considering a single overhead crane, SLKJ Crane stands ready to partner with you. We provide industry-leading products, tailor-made solutions, and exceptional customer service to help you achieve operational excellence. Visit our website at www.slkjcrane.com for more information and to consult with our experienced team of professionals today.

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice