How to Choose a Cost-Effective Overhead Crane? 5 Key Metrics to Save 30% on Costs

In industrial manufacturing, logistics, warehousing, and construction, overhead cranes and gantry cranes are essential for boosting productivity. However, with numerous brands and significant price variations in the market, selecting a high-performance, low-maintenance crane is critical for procurement decisions.

Statistics show that 70% of buyers discover post-purchase issues such as insufficient load capacity, unstable operation, or high maintenance costs. Meanwhile, companies that choose the right equipment save 30% on operational costs and increase productivity by 20%.

This article combines industry data and practical experience to analyze 5 key metrics, helping you make an informed purchase and avoid costly mistakes!

5 Key Metrics for Choosing the Right Overhead Crane

1. Load Capacity: Bigger Isn’t Always Better – Match Your Needs to Save Costs

Common Mistake: Many buyers think “higher tonnage = better,” but oversized cranes increase initial costs, energy consumption, and maintenance expenses.

Data Insights:

- 40%+ of companies buy cranes with 20%-50% excess capacity, leading to 15% higher annual energy and maintenance costs.

- Solution: Calculate peak load + 10%-20% safety margin.

- Example: Max daily load = 10 tons → Choose a 12-ton crane.

Key Takeaway:

“Buying bigger ‘just in case’ is the biggest myth in crane procurement. Precise matching cuts costs and boosts efficiency.”

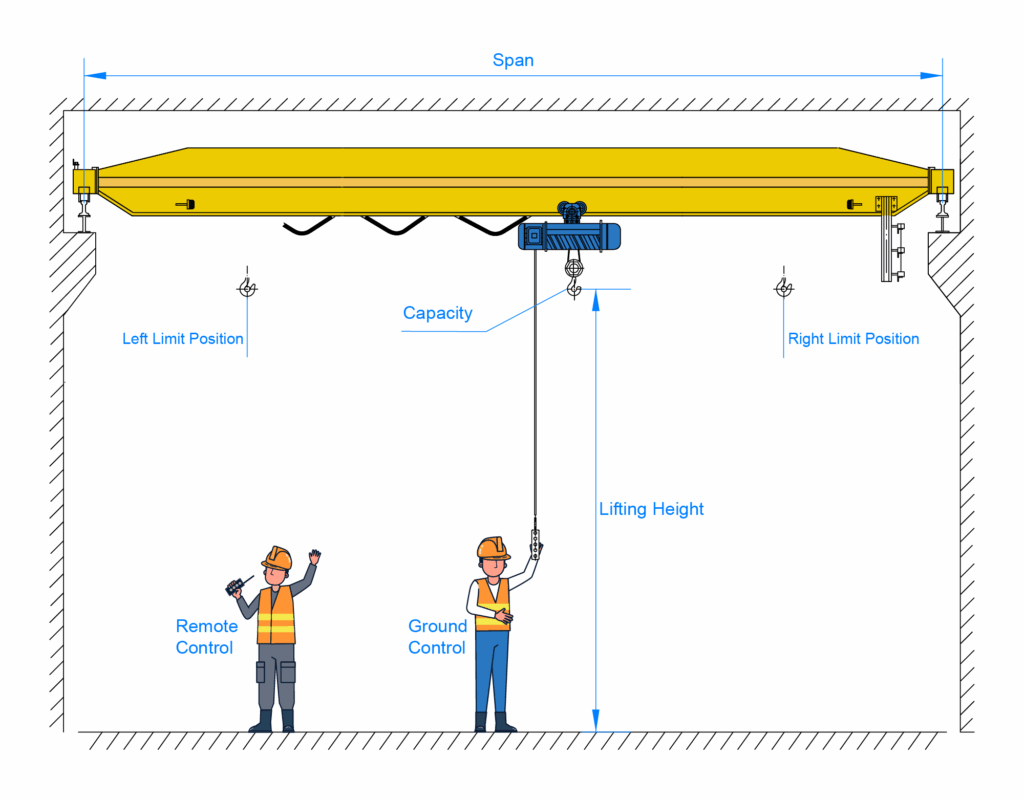

2. Span & Lifting Height: Optimize Workshop Space Utilization

The span and lifting height of an overhead crane directly impact workshop layout and operational efficiency.

Industry Recommendations:

| Application | Recommended Span | Recommended Lifting Height |

|---|---|---|

| Small/medium workshops | 5m–15m | 6m–10m |

| Large factories/ports | 15m–30m+ | 10m–20m+ |

Case Study: An auto parts factory optimized span design, saving 8% in space and reducing lifting time by 5%.

3. Drive System: Variable Frequency Drive (VFD) vs. Traditional – Which Saves More?

- Traditional (fixed-speed motor): Lower upfront cost but higher energy use and mechanical wear.

- VFD system: Higher initial cost (20%-30% more) but lower energy consumption (15%-25% savings) and smoother operation.

Comparison:

| Metric | Traditional Drive | VFD Drive |

|---|---|---|

| Initial Cost | Low | High (+20%-30%) |

| Energy Use | High | Low (15%-25% savings) |

| Maintenance | Higher (wear & tear) | Lower |

| Best For | Low-frequency use | High-frequency, precision tasks |

Conclusion: If the crane operates >4 hours/day, VFD pays for itself in 2-3 years.

4. Safety Certifications: Are CE & ISO Standards Really Important?

Uncertified cranes pose safety risks and may lead to insurance denial or legal penalties.

Key Certifications:

- CE Marking (EU compliance)

- ISO 9001 (Quality Management)

- ASME B30 (U.S. safety standard)

Case Study: A company fac

4. Safety Certifications: Are CE & ISO Standards Really Important?

Uncertified cranes pose safety risks and may lead to insurance denial or legal penalties.

Key Certifications:

- CE Marking (EU compliance)

- ISO 9001 (Quality Management)

- ASME B30 (U.S. safety standard)

Case Study: A company faced €500K in fines + shutdowns after an accident involving a non-CE-certified crane.

5. After-Sales Service: Avoid “Affordable to Buy, Expensive to Maintain”

Maintenance accounts for 40% of a crane’s lifecycle cost (LCC). Choose suppliers with local support and long-term warranties.

Recommendations:

✅ 2+ years warranty on core components

✅ 24/7 emergency response

✅ Spare parts availability to minimize downtime

Final Checklist for Your Crane Purchase

✔ Right-size load capacity – Avoid overspending

✔ Optimize span & lifting height – Maximize space

✔ VFD for high-frequency use – Long-term savings

✔ CE/ISO certified only – Legal & safety compliance

✔ Reliable after-sales service – Lower lifetime costs

Take Action Now!

📞 Consult our crane experts today for a free load calculator & customized solution – save 30% on procurement costs!

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice