How to Calculate Bridge Crane Capacity: The Ultimate Guide for Industrial Buyers

Introduction to Bridge Crane Capacity Calculations

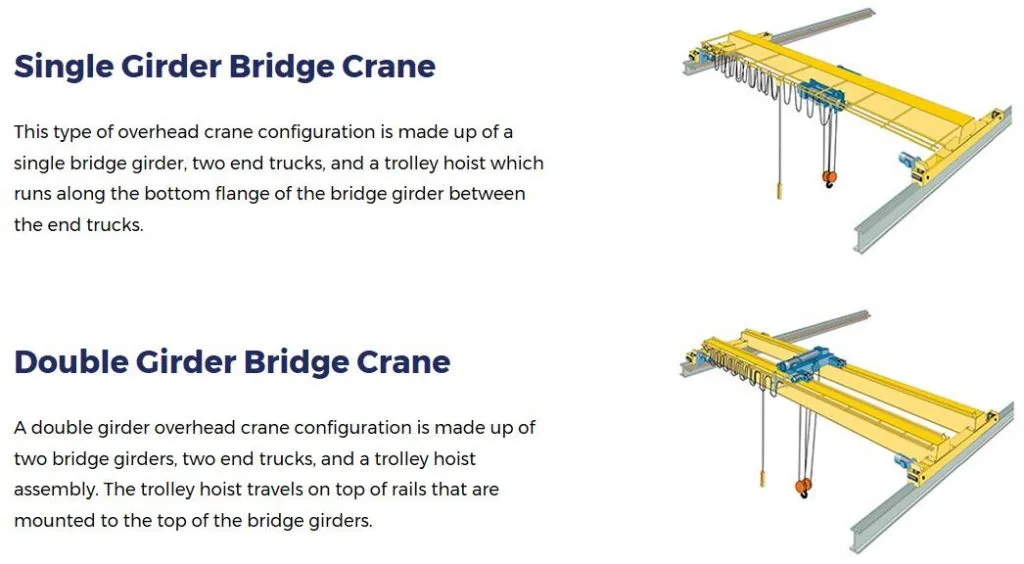

Understanding how to properly calculate bridge crane capacity is fundamental for any industrial operation requiring heavy lifting solutions. Whether you’re evaluating a single girder overhead crane for light manufacturing or a double girder EOT crane for heavy-duty applications, accurate capacity determination ensures both operational efficiency and workplace safety.

This comprehensive 5,000-word guide will cover:

- The engineering principles behind overhead crane load ratings

- Step-by-step calculation methods with practical examples

- Common mistakes that lead to dangerous overload situations

- Real-world case studies demonstrating proper capacity planning

- Maintenance factors that affect long-term load capacity

Understanding Bridge Crane Load Capacity Fundamentals

What Does "Rated Capacity" Really Mean?

Every industrial bridge crane comes with a manufacturer-specified rated capacity – the maximum safe working load (SWL) it can handle under normal operating conditions. For a 10-ton overhead traveling crane, this means:

- The main crane girder must support 10 tons at minimum

- The hoist and trolley system must be rated for 10 tons

- All structural components maintain safety factors (typically 3:1 or 5:1)

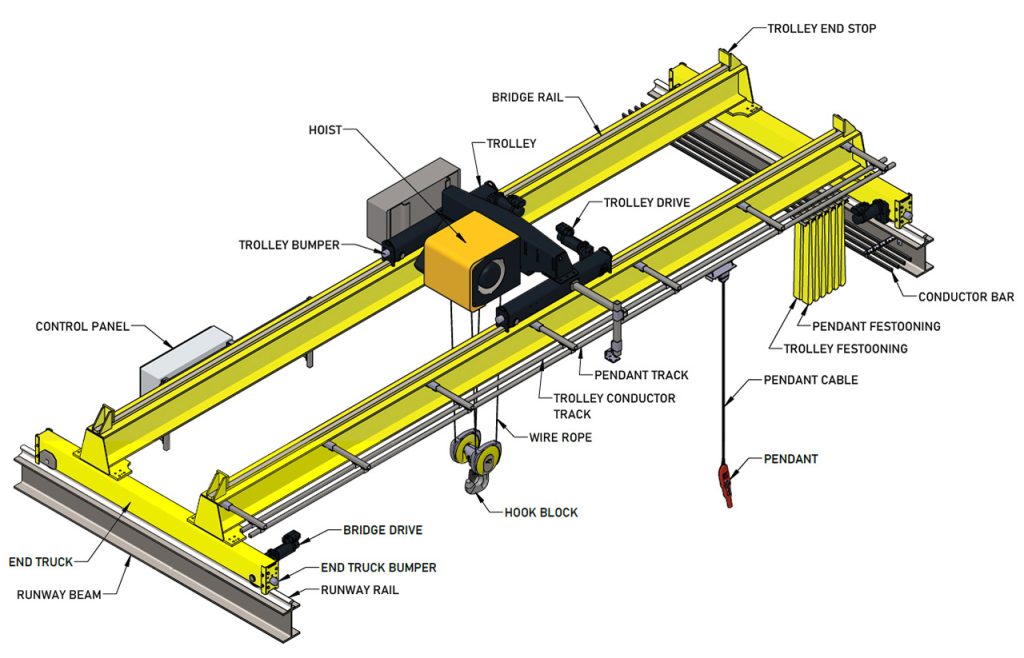

Key Components Affecting Total System Capacity

Main Bridge Girder Strength

- Single girder vs double girder configurations

- Steel grade and cross-sectional properties

- Deflection limits (usually ≤ span/600)

End Truck and Runway System

- Wheel load distribution calculations

- Runway beam stiffness requirements

Hoisting Mechanism Specifications

- Electric wire rope hoist vs chain hoist capacities

- Trolley frame structural integrity

The Complete Bridge Crane Capacity Calculation Process

1: Determine Your Actual Load Requirements

Calculate:

- Heaviest individual component weight

- Weight of lifting attachments (spreader beams, magnets, etc.)

- 25% dynamic load factor for sudden movements

Example Calculation:

Base load: 18 tons

Lifting beam: 0.8 tons

Dynamic factor: 18 × 0.25 = 4.5 tons

Total Required Capacity: 18 + 0.8 + 4.5 = 23.3 tons

→ Select 25-ton crane 2: Verify Bridge Girder Capacity

Use the modified uniform load formula:

Capacity = (S × Fy × Z) / (L × SF)

Where:

S = Section modulus

Fy = Yield strength

Z = Plastic section factor

L = Span length

SF = Safety factor (typically 1.5-2.0) 3: Check Hoist and Trolley Specifications

- Verify hoist service class matches your duty cycle

- Confirm trolley wheel loads don’t exceed rail capacity

- Ensure proper brake capacity for your load

Real World Application Case Studies

Automotive Parts Manufacturer: Optimizing Production Line Capacity

A Tier 1 auto supplier replaced their aging 5-ton jib cranes with a customized 8-ton double girder system featuring:

- 25% increased duty cycle rating

- Anti-sway control for precision positioning

- Smart load monitoring system

Results:

- 40% reduction in load handling time

- Zero overload incidents in 3 years of operation

- ROI achieved in 14 months

Steel Service Center: Upgrading for Heavy Coil Handling

Facing frequent overcapacity alarms with their existing 15-ton cranes, a Midwest steel processor installed:

- 20-ton capacity bridge cranes with reinforced girders

- Variable frequency drives for smooth acceleration

- Automated load weighing system

Outcomes:

- Eliminated unplanned downtime from overload shutdowns

- Increased average daily throughput by 18 tons

- Reduced maintenance costs by 32%

Critical Mistakes in Capacity Planning

The Hidden Costs of Underestimating Loads

Attachment Weight Oversights

- Common error: Forgetting vacuum lifter or magnet weights

- Solution: Always include all below-the-hook devices

Dynamic Load Miscalculations

- Real-world example: A foundry crane handling molten metal requires 25% higher capacity than static weight

Duty Cycle Misclassification

- Running a Class C (light duty) crane in Class D (medium duty) applications reduces lifespan by 60%

Advanced Capacity Considerations

Fatigue Life and Long-Term Capacity

The 10-year rule:

- After a decade of heavy use, consider:

- 5-10% derating for standard cranes

- Non-destructive testing (NDT) for critical welds

- Girder deflection re-measurement

Special Application Requirements

Explosion-Proof Cranes

- Typically require 15% capacity buffer for heavier enclosures

Clean Room Bridge Cranes

- Stainless steel construction adds 8-12% to dead weight

Magnetic Lifting Systems

- Electromagnets may need 20-30% extra capacity for secure holding

Maintenance Practices That Preserve Capacity

Quarterly Capacity Assurance Checks

Structural Inspections

- Measure girder deflection against original specs

- Check for cracked welds or deformed sections

Hoist System Verification

- Brake torque testing

- Wire rope diameter measurements

Runway Alignment

- Laser alignment for rail systems

- Wheel flange wear patterns

Selecting Your Ideal Bridge Crane

Use this decision matrix:

| Factor | Light Duty (<10 tons) | Heavy Duty (10-50 tons) | Extreme Duty (50+ tons) |

|---|---|---|---|

| Girder Type | Single | Double | Reinforced Double |

| Hoist Type | Chain | Wire Rope | Multiple Wire Rope |

| Duty Cycle | Class C | Class D/E | Class F |

| Control | Pendant | Radio | Cabin+Radio |

Conclusion and Next Steps

Proper bridge crane capacity calculation requires understanding both theoretical engineering principles and practical operational factors. By following this comprehensive guide, you can:

- Select the optimally sized overhead lifting system

- Avoid costly over-engineering or dangerous under-sizing

- Ensure compliance with all safety regulations

Ready to Specify Your Crane?

[Contact our engineering team] for a free capacity analysis and system recommendation tailored to your exact needs.

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice