Gantry Cranes for Ports, Shipyards & Factories | SLKJCrane Global Supplier

This article takes a detailed look at gantry cranes.

You will learn more about topics such as:

- What is a gantry crane?

- Types of gantry cranes

- How gantry cranes are made

- Uses for gantry cranes

- And much more …

What is a Gantry Crane?

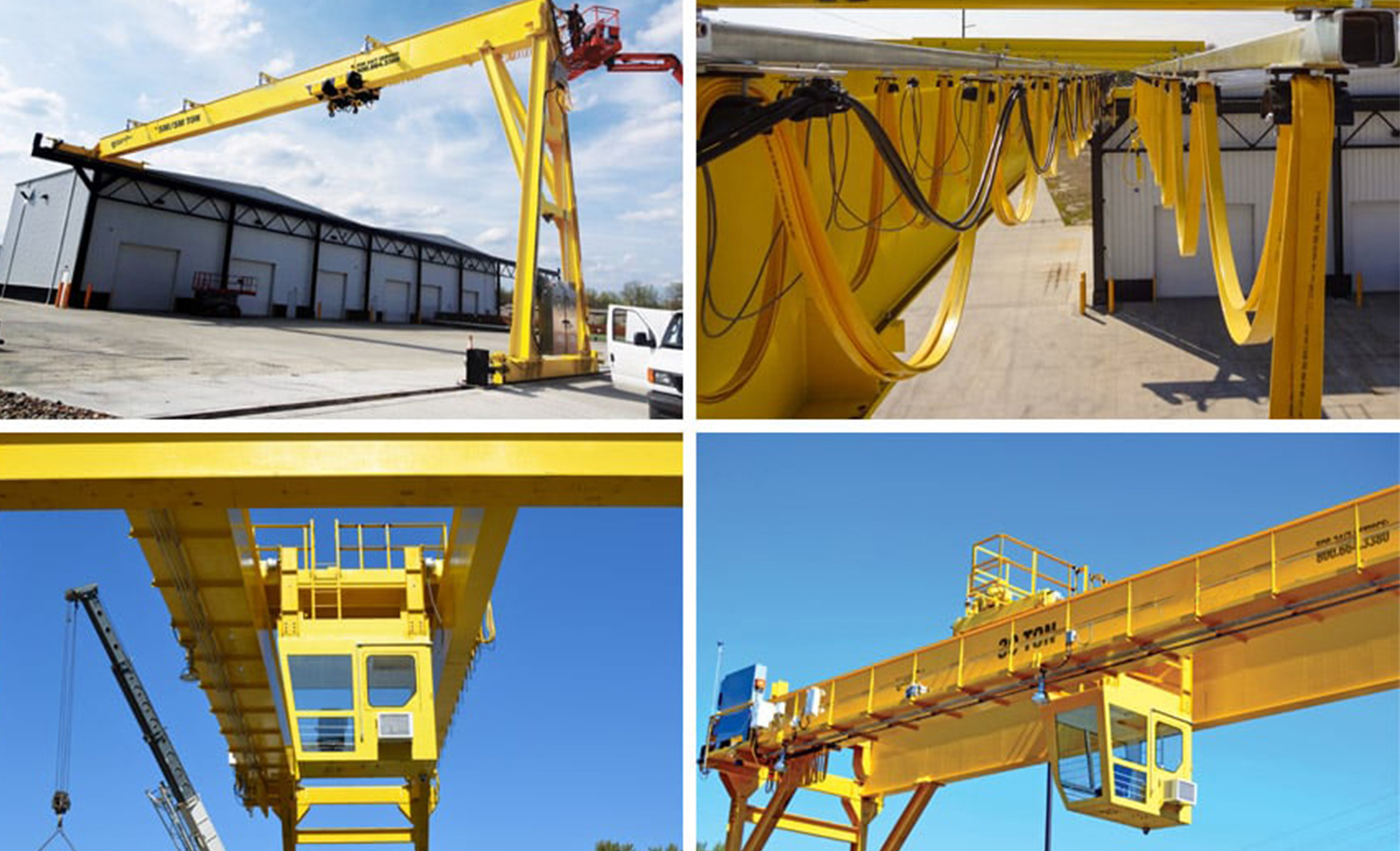

A gantry crane is a type of lifting equipment distinguished by its large, gate-shaped structure, which resembles a massive doorway when viewed from a distance—hence the name. It typically consists of a main beam, supporting legs, lower crossbeam, hoisting trolley, crane traveling mechanism, and electrical systems. Gantry cranes are widely used in ports and harbors, shipbuilding, subway construction, hydropower projects, aerospace manufacturing, warehousing and logistics, and building construction. As an essential material handling tool in modern industry, a gantry crane significantly reduces manual labor intensity, enabling mechanized and automated lifting operations. This not only improves workplace safety but also boosts operational efficiency, making it an indispensable solution for heavy-duty and large-scale material handling needs.

Why Gantry Cranes Are Essential for Modern Material Handling

The demands of today’s industries In production—speed, precision, and safety—have never been higher. Moving oversized, heavy, or irregularly shaped loads with forklifts or manual labor is not only inefficient but also risky. Gantry cranes solve these problems with:

High Lifting Capacity – Capable of handling anything from a few tons to several hundred tons.

The Flexibility Of Design – The span, height, type of lifting attachment, and operating speed of each mechanism can all be customized according to specific requirements.

Productivity Gains – Reduces downtime, speeds up operations, and enhance productivity.

Main Types of Gantry Cranes

SLKJCrane offers multiple gantry crane configurations type to meet diverse customer requirements:

Portable Gantry Crane:Lightweight and flexible, it is suitable for light hoisting tasks in workshops or construction sites

Semi Gantry Crane:One leg runs on a rail, the other supported by an elevated structure, saving floor space.

Full Gantry Crane:The four outriggers run on the track, making it more suitable for large scale outdoor operations

Shipyard Gantry Crane:It is a kind of super-large tonnage, span and lift special gantry crane for shipbuilding, specifically used for the construction, maintenance and repair of shipbuilding and Marine engineering structures.

Single Girder Gantry Crane:Simple structure, cost-effective, suitable for light to medium loads.

Double Girder Gantry Crane:One leg runs on a rail, the other supported by an elevated structure, saving floor space.

Rail Mounted Gantry (RMG) Crane– Common in container terminals and rail yards, further classified into

Rubber Tired Gantry (RTG) Crane:Highly mobile container handling cranes without fixed rails.

Industry Applications and Benefits

Gantry cranes are versatile and widely used in multiple sectors:

Ports & Container Terminals

Efficient container stacking and vessel loading/unloading, reducing vessel turnaround time.

Shipyards

Lifting ship sections, propellers, and marine engines.

Logistics & Freight Yards

Handling containers, heavy pallets, and specialized cargo.

Manufacturing

Moving heavy machinery, molds, and assembly components.

Construction

Lifting steel structures, precast concrete, and large equipment.

Energy & Infrastructure

Install large generator units and complete the transportation of large Bridges and their components in the girder yard, etc

Load Capacity & Dimensional Reference

| Application Area | Typical Capacity Range | Common Span | Notes |

|---|---|---|---|

| Workshop / Light Manufacturing | 1 – 10 tons | 7.5 – 22.5 m | Single girder, portable options available |

| Medium Manufacturing / Processing | 10 – 50 tons | 12 – 35 m | Single or double girder |

| Ports & Container Handling | 40 – 70 tons | 20 – 40 m | RMG or RTG |

| Shipyards & Offshore | 100 – 900+ tons | 30 – 100+ m | Heavy-duty double girder |

| Construction / Infrastructure | 20 – 200 tons | 12 – 50 m | Often semi-gantry or mobile configurations |

SLKJCrane’s Design & Manufacturing Process

We follow strict international standards to ensure safety, performance, and durability.

1.Demand analysis

Determine the lifting capacity, span, lifting height, working level, working speed of each mechanism and other level parameters.

Working environment

2.Advanced design methods

Utilizing 3D modeling technology, structural simulation technology, and finite element analysis technology to conduct various tests on the product

3.Steel structure manufacturing

High strength steel is used, with automatic full penetration welding and anti corrosion treatment

4.Assembly and testing

Conduct full load tests, safety system inspections and certifications

5.International compliance

Conforms to multiple international standards such as ISO and CE

Global Project Highlight: Middle East Delivery

We recently delivered a 65-ton Rail-Mounted Gantry Crane to a Middle Eastern container terminal, engineered for high temperatures and dusty environments. Key features included:

Dust-proof drive and sealed electrical systems

Energy-efficient control systems to reduce operational costs

Remote monitoring for predictive maintenance

Within the first month of operation, container handling efficiency increased by 30%.

FAQ

FREQUENTLY ASKED QUESTIONS

Here are some common questions and answers about gantry cranes that may help you clear up your doubts. If not, please initiate a consultation below and let our professional technical department provide you with an answer

What is a gantry crane?

A crane where the girder is supported by legs moving on rails or wheels, suitable for indoor and outdoor lifting.

What is the difference between a gantry crane and an overhead crane?

A gantry crane uses legs to support the bridge and can run on rails or wheels placed on the ground, making it suitable for outdoor yards or areas without building support.

An overhead crane, also called a bridge crane, is supported by building columns or beams and operates along elevated runways inside a facility. Gantry cranes offer more mobility, while overhead cranes are better for permanent indoor lifting operations.

How to choose the right gantry crane capacity?

To choose the correct capacity, consider the maximum load weight you will lift, including the weight of any lifting devices such as spreader beams or grabs. Always select a capacity slightly higher than your heaviest load for safety and durability. For example, if your heaviest load is 8 tons, a 10-ton gantry crane would be a safer choice. Also factor in future expansion needs and local safety regulations.

What are the main types of gantry cranes?

Portable, semi gantry, full gantry, single girder, double girder, RMG (container, bulk, specialized), RTG, and shipbuilding gantry cranes.

What are the key components?

The main beam of the crane, the outriggers of the crane, the lower crossbeam of the crane, the hoisting trolley, the traveling mechanism of the large car, the power and control system of the crane, etc.

How are they used in different industries?

From ports to shipyards, manufacturing plants to construction sites, they handle everything from containers to massive infrastructure components.

What are the common parts for gantry cranes?

Overload limiters, lifting height limiters, brakes, brake pads, steel wires, pulleys, wheels, etc.

How are gantry cranes installed and maintained?

Installation includes site preparation, track or wheel calibration, main beam assembly, hoisting device installation and load testing. Maintenance requires lubrication, safety checks, motor and reducer testing, and control system calibration.

What certifications are needed for different regions?

Europe – CE Certification, EN Standards

Middle East – GCC Compliance, ISO, and port authority approvals

North America – OSHA, CMAA Standards

Asia – China GB, Japan JIS, India BIS Standards

The strength and professionalism of SLKJCrane

Why Choose SLKJCrane for Your Global Projects

Extensive International Experience – Projects in Asia, Europe, the Middle East, and Africa.

Tailored Solutions – Designed to match specific load, environmental, and operational requirements.

Full-Service Approach – From engineering and manufacturing to installation, training, and after-sales.

Fast Delivery & Cost Efficiency – High quality without unnecessary expense.

SLKJCRANE – It is a crane manufacturer specializing in the production of gantry cranes and overhead bridge cranes. The industry has accumulated over 20 years of experience

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice