Free Standing Gantry Crane Solutions for Existing and Leased Buildings

Why Many Workshops Struggle to Install an Overhead Crane

A lot of workshops, warehouses and fabrication plants want an overhead crane, but the building simply does not cooperate. Typical problems include:

-

Roof beams are too light to carry crane and load

-

Columns are far apart or not aligned for a runway

-

Clear height is limited by HVAC ducts, lighting or old trusses

-

The building is leased, and structural changes are not allowed

-

Civil work and shutdowns are more expensive than the crane itself

In these situations, buyers often try to:

-

Add more forklifts and manual handling

-

Use small chain blocks everywhere

-

Delay the lifting upgrade until “next project”

The result is the same: low efficiency, higher safety risk and slow material flow.

A free standing gantry crane is designed exactly for this kind of workshop: where you urgently need a crane, but you cannot or do not want to rebuild the building.

What Is a Free Standing Gantry Crane(Rubber tire gantry crane)?

A free standing gantry crane is a self-supporting crane system installed on the floor, not on the building.

Main features:

-

Steel columns and end carriages form an independent frame

-

One or two girders support the hoist and trolley

-

The crane travels along a defined path on rails or on wheels

-

Loads are transferred directly into the floor or local foundations

In other words, you get the benefits of an overhead crane – safe, linear, overhead handling – without relying on roof beams or wall brackets.

Main accessories and components

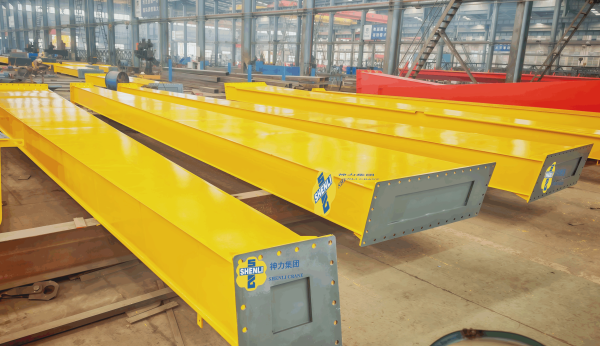

The main beam is welded with high-strength killed steel. The cross-section presents a rectangular structure, featuring good stability, high strength, great rigidity and a long service life. It is the main load-bearing component of the crane.

The outriggers are the main load-bearing components of a crane. It is a box structure formed by welding steel plates together. When it is in operation, the force is clearly applied, the force transmission is direct, the component strength is high, and the stability is good. It is the safety guarantee for lifting operations.

Electric hoists are the core components for cranes to lift heavy objects. Designed in accordance with both FEM and GB standards. It features a compact structure, novel appearance, energy conservation and consumption reduction. Stepless speed control, high-end positioning function and ultra-quiet design make its performance even more outstanding.

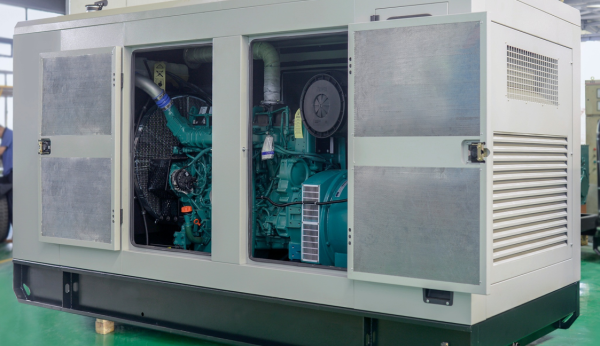

Diesel generator sets are the main equipment for power supply of tire-mounted gantry cranes. It features a silent design, a compact body and powerful performance. It provides great convenience for the flexibility of crane relocation operations.

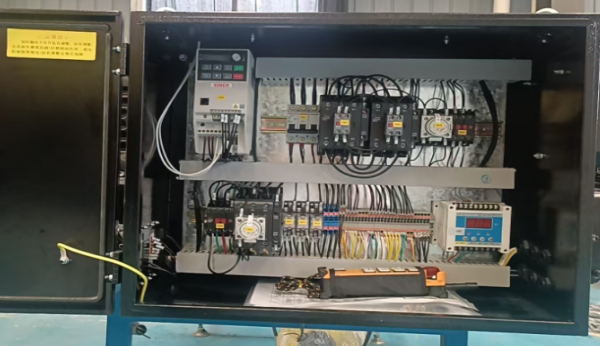

The crane adopts an advanced electrical control system, making the lifting operation more intelligent and convenient. It adopts variable frequency speed control, with a wider speed regulation range (speed regulation ratio 1:10), and each mechanism operates more stably. The overload limit function makes lifting operations safer.

The traveling mechanism of the crane adopts a rubber tire structure, which has a stronger load-bearing capacity. Chain drive enables the mechanism to minimize the buffering force when starting and braking, making the crane travel more smoothly.

Overhead Crane vs Wall Crane vs Free Standing Gantry Crane

Before deciding on a free standing gantry crane, it helps to compare it with other common options.

Main Types of Gantry Cranes

SLKJCrane offers multiple gantry crane configurations type to meet diverse customer requirements:

Ceiling Mounted Overhead Crane

Advantages

-

Maximum headroom, ideal for tall loads

-

Large coverage area with long runways

-

Clean shop floor without columns inside the bay

Limitations in existing buildings

-

Requires strong building structure

-

Needs runway beams anchored to columns or additional steel

-

High civil and fabrication cost if the building is not designed for a crane

-

Long design–approval–installation cycle

Wall Mounted or Wall Travelling Crane

Advantages

-

Good for localized workstations along a wall

-

Saves floor space compared with regular gantries

Limitations

-

Again depends on wall strength and anchor design

-

Limited coverage and lifting heights

-

Not suitable if the building walls are not engineered for such loads

Free Standing Gantry Crane

Advantages

-

Independent structure; no structural load on roof or walls

-

Can be installed in almost any existing, rented or multi-tenant building

-

Easier to plan, budget and approve because building modification is minimal

-

Can be disassembled, relocated or extended with relatively low cost

Typical trade-offs

-

Columns occupy a narrow strip of floor on both sides

-

Overhead coverage is defined by the span and runway length you choose

-

Floor bearing capacity must be checked or locally reinforced

For many retrofit projects, the free standing gantry crane represents the best balance between structural feasibility, cost and performance.

Key Design Decisions for a Free Standing Gantry Crane

When planning a free standing gantry crane, you are essentially designing a small “independent lifting building” inside your workshop. The following points are critical.

Capacity and Duty Class

Start with the load:

-

Normal working load: weight of parts you handle most of the time

-

Maximum required load: the heaviest equipment, mould or bundle

-

Duty: occasional maintenance lifting or continuous production

From this, we decide:

-

Rated capacity (with 10–25% safety margin)

-

Hoist type and duty class (light, medium or heavy duty)

-

Motor power and frequency inverter configuration

Span, Hook Coverage and Hook Approaches

The span is the distance between the two column lines. It should cover:

-

The full working width of your bay

-

Clearance for machines, racks and passageways

-

Any future additional line or workstation

We also consider:

-

Minimum hook approach: how close the hook can get to each side

-

End hook distance: clearance at runway ends

-

Lifting height vs. lowest obstruction above the crane

Proper planning here ensures you do not pay for “extra span you never use”, and you avoid dead zones where the hook cannot reach.

Runway Layout and Floor Loads

Next is the length of runway and how it fits into your layout:

-

Does the crane serve one production line or multiple lines?

-

Do you need full length coverage from loading bay to packing area?

-

Are there doors, pits or machines that the columns must bypass?

For each column and wheel, SLKJCrane engineers calculate:

-

Maximum vertical wheel loads for the selected crane duty

-

Horizontal forces from acceleration, braking and skew correction

-

Required floor thickness or foundation pads

This allows you to know in advance whether:

-

The existing slab is sufficient

-

Local thickening is enough, or

-

Separate strip foundations are recommended

Free Standing Gantry Crane Configurations from SLKJCrane

Depending on your building and process, SLKJCrane typically proposes one of the following configurations.

Indoor Single Girder Free Standing Gantry Crane

-

Capacity range: 1–20 t

-

Economical steel structure, low self-weight

-

Good choice for medium-height workshops and process lines

-

Can work with low headroom electric hoists to maximize hook height

Typical applications:

-

Machine shops handling shafts, gearboxes and weldments

-

Fabrication lines moving parts between stations

-

Maintenance bays for pumps, motors and equipment

Indoor Double Girder Free Standing Gantry Crane

-

Capacity range: 10–50+ t

-

Higher stiffness and better hook height utilization

-

Suitable for heavy tools, dies, moulds and large components

-

Allows advanced options: maintenance platforms, crab-type trolley, etc.

Typical applications:

-

Heavy fabrication and assembly shops

-

Steel processing and coil handling

-

Large mould / die handling in automotive and plastic industries

Rubber Tyred Free Standing Gantry Crane (Mobile)

-

End carriages equipped with rubber wheels instead of fixed rails

-

Travels directly on the floor, sometimes both indoor and outdoor

-

Modular steel structure for easier relocation

Best for:

-

Leased facilities where the layout changes over time

-

Combined indoor–outdoor handling zones

-

Customers who plan to move to a larger plant later and want to keep the crane

Hybrid Solutions: Semi Free Standing Systems

In some buildings, one side of the crane can be connected to a strong column line, while the other side uses free standing columns.

This semi-free-standing solution can:

-

Reduce the number of columns on the floor

-

Save some steel weight and project cost

-

Still avoid heavy modifications on weak or non-structural walls

Our engineers evaluate this option case by case, balancing cost, safety and practicality.

Project Cost and Timeline Considerations

Free standing gantry cranes often win not only on technical feasibility, but also on the overall project cost and schedule.

Where You Save Money

Compared with a full overhead crane retrofit, you typically save on:

-

Structural analysis and redesign of the building frame

-

Fabrication of heavy runway beams and column brackets

-

Floor-to-roof bracing and tie-backs

-

Temporary removal of roof panels, cladding or services

You still invest in a robust crane structure, but you avoid “hidden” cost that does not directly increase your lifting capacity.

Installation and Downtime

Because the structure is independent:

-

Columns, girders and crane mechanisms can be pre-assembled

-

On-site welding and cutting are minimized

-

Installation often can be completed during a planned weekend shutdown or short holiday

For factories where every hour of production matters, this reduced downtime is often more valuable than the material cost itself.

Example Project Scenarios

Retrofit in a 20 Year Old Fabrication Plant

A fabrication plant with a 20-year-old steel building wanted a 10 t crane along one bay. Engineering checks showed that the original rafters and columns could not support a conventional overhead crane without heavy reinforcement.

SLKJCrane solution

-

10 t single-girder free standing gantry crane

-

Span aligned with the existing bay width; runway length 36 m

-

Local floor verification and small foundation pads under each column

Outcome

-

No roof or column strengthening

-

Installation and commissioning completed in a short shutdown

-

Safer plate and profile handling, less forklift traffic in the bay

Leased Logistics Warehouse with Mixed Loads

A logistics company leased a warehouse to handle both palletized goods and heavy machinery. They needed crane capacity, but all civil and structural modification had to be reversible at the end of the lease.

SLKJCrane solution

-

Mobile rubber-tyred free standing gantry crane, 5 t capacity

-

Adjustable span to suit different aisles over the project lifetime

-

Power supply designed with flexible cable management

Outcome

-

Full lifting capability without touching the building structure

-

Crane can be moved when layout changes or when the company relocates

-

Investment keeps value beyond the current building lease term

What SLKJCrane Provides with a Free Standing Gantry Crane

When you choose SLKJCrane as your partner, you receive more than just a steel structure and hoist. We support you through the whole project:

-

Layout consulting – we help you decide where the crane delivers the most benefit

-

Structural calculation – wheel loads, foundation suggestions and stability checks

-

Customized design – tailored span, height and duty class for your process

-

High-quality hoists – reliable lifting with overload protection and smooth control

-

Electrical and safety systems – limit switches, buffer stops, anti-collision options

-

After-sales service – spare parts, technical support and maintenance advice

Our goal is to deliver a free standing gantry crane that fits your building, process and budget – not just a standard catalogue product.

How to Prepare Your Enquiry

To receive a precise solution and budget from SLKJCrane, please include:

-

Lifting capacity (t)

-

Span (m) and approximate runway length (m)

-

Required lifting height (floor to hook)

-

Indoor / outdoor use, temperature and environment (dust, humidity, corrosion)

-

Existing building drawings, photos or simple sketches if available

-

Power supply (voltage, frequency, phase)

-

Expected working hours per day and per shift

Our engineering team will review your information and propose one or more free standing gantry crane options, including a comparison with possible overhead or hybrid solutions.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

FREQUENTLY ASKED QUESTIONS

———Free Standing Gantry Crane

Is a free standing gantry crane only for indoor use?

No. While many free standing gantry cranes are installed indoors, we also design outdoor models with weatherproof protection, corrosion-resistant coatings and suitable covers for electrical components.

Will the columns take too much floor space?

Column lines are usually placed along the edge of your working zone or near existing building columns. With proper layout planning, the loss of floor space is limited, and the gain in overhead handling efficiency is much greater.

Can I combine a free standing gantry crane with existing small jib cranes or hoists?

Yes. In many projects, a free standing gantry crane handles long-distance transport, while jib cranes or workstation hoists handle local tasks. We can help you coordinate the working envelopes to avoid interference.

What standards do SLKJCrane free standing gantry cranes follow?

We design and manufacture according to relevant ISO/FEM standards and can adapt to local regulations and electrical codes in your country or region.

How long does it normally take from order to commissioning?

Lead time depends on capacity, customization level and shipping distance. After we know your detailed requirements, we can give you an estimated schedule including design, fabrication, delivery and on-site installation guidance.

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice