Explosion-Proof Overhead Cranes Lineup for Hazardous Areas (LB / LXB / LHB / QB / QBE / Clean EX)

In hazardous plants where flammable gases, vapors or combustible dust may occur, material handling must control ignition risks. Our explosion-proof overhead crane lineup provides engineered options from compact single-girder systems to heavy-duty open-winch process cranes—configured to your area classification (gas or dust), duty profile, and building geometry.

Important note: Final selection follows your site’s hazardous area classification and project specification. We do not state certificates we don’t possess; component protection concepts and documentation are listed in proposals upon request.

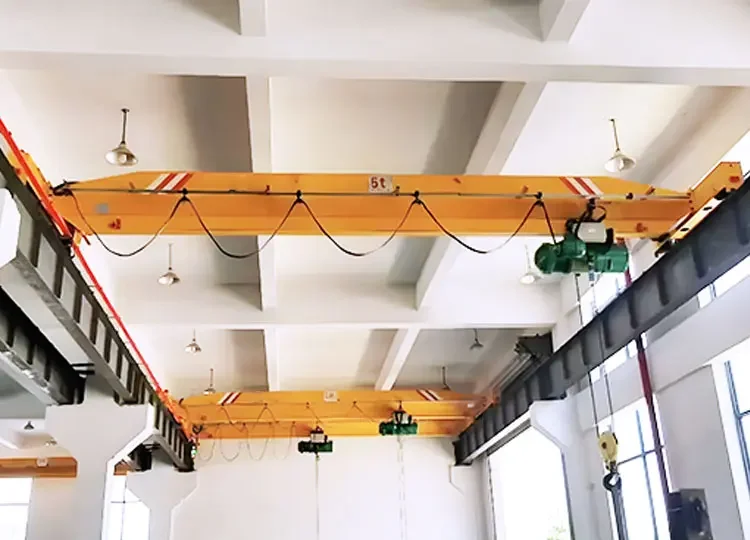

1) LB — Explosion Proof Single Girder Overhead Crane

Best for: general bay lifting in hazardous gas or dust areas with limited headroom and moderate duty.

Key features

-

Compact low-headroom hoist trolley to maximize hook height

-

EX motors, brakes, limit switches, enclosures; grounded/bonded structure

-

Smooth starts/stops via VFD; optional creep speed and anti-sway logic

-

Pendant or EX-ready radio control (per site rules)

Typical working ranges (indicative)

-

Capacity: 1–20 t Span: 5–22 m Lift: 6–24 m

-

Duty: medium (e.g., regular production & maintenance)

Typical applications: solvent handling, paint shops, skids and pumps, drum transfer.

2) LXB — Explosion-Proof Single-Girder Underslung Crane

Best for: congested bays or buildings without room for top-running runways.

Key features

-

Suspension/underslung running on the lower flange of runway beams

-

Tight approach dimensions, excellent area coverage on complex bays

-

EX electricals and anti-spark measures identical to LB

Typical working ranges

-

Capacity: 0.5–10 t Span: 3–16 m Lift: 6–18 m

-

Duty: light–medium

Typical applications: packaging lines, assembly cells, battery rooms with crowded pipe racks.

3) LHB — Explosion-Proof Double-Girder (Hoist) Overhead Crane

Best for: higher capacities and longer spans while keeping hoist-based architecture.

Key features

-

Double-girder bridge with EX wire-rope hoist trolley

-

Higher hook approach, service walkway options, maintenance access

-

VFD travel on trolley/bridge; load display, inching, and zoning interlocks optional

Typical working ranges

-

Capacity: 10–50 t Span: 10–30+ m Lift: 8–30 m

-

Duty: medium–heavy (frequent starts, longer travel)

Typical applications: reactors, mixers, filter presses, tank farms.

4) QB — Explosion-Proof Open-Winch Double-Girder Overhead Crane

Best for: process duty, heavy loads, high precision positioning, and higher thermal margins.

Key features

-

Open-winch hoisting with robust gear/motor/brake assemblies

-

Tailored speed profiles (hoist/trolley/bridge), multi-level protections

-

Thermal management for drives/resistors; guided cabling & EX glands

-

Optional operator cabin, maintenance platforms, redundant brakes

Typical working ranges

-

Capacity: 20–200+ t Span: 12–35 m Lift: 12–30 m

-

Duty: heavy–severe (continuous or near-continuous process use)

Typical applications: petrochemical reactors, large mold handling, LNG/energy modules.

5) QBE — Explosion-Proof Double-Trolley, Double-Girder Crane

Best for: synchronized lifts, turning/tilting, balanced handling of long or awkward loads.

Key features

-

Two trolleys with synchronized control for tandem or turning operations

-

Coordinated VFD and interlocks; optional load-sharing & anti-skew logic

-

Same EX electrical philosophy as QB, with added synchronization safety

Typical working ranges

-

Capacity (each trolley): 10–80 t (project-specific)

-

Span / Lift: as engineered to application

-

Duty: heavy (precision process moves)

Typical applications: pressure vessels, long shafts, molds, tank assemblies.

6) Clean Explosion-Proof Overhead Cranes

Best for: hazardous and cleanliness-controlled environments such as batteries, pharma, specialty chemicals.

Key features

-

Clean-area friendly finishes, sealed enclosures, dust-tight cable management

-

Low-particle design on walkways and housings; stainless hardware where needed

-

EX electricals and grounding per area classification; optional positive-pressure panels where specified

Typical working ranges

-

Capacity: 0.5–20 t (single-girder), 10–50 t (double-girder)

-

Span / Lift: per bay layout Duty: light–medium–heavy (as specified)

Typical applications: NMP/electrolyte rooms, coating/drying lines, ethanol-based pharma rooms.

Engineering Essentials for All EX Models

-

Explosion-protected electricals: hoist/bridge motors, brakes, limiters, junction boxes, pushbutton stations; enclosure/gland selection for gas or dust atmospheres.

-

Controls & safety: VFD with safe-stop logic, overload/overspeed monitoring, travel limits; intrinsically safer low-energy circuits where applicable.

-

Anti-spark & static control: full-path grounding/bonding, anti-static cable systems, guarded rubbing interfaces; non-sparking contact materials where required by spec.

-

Thermal management: component layout and cooling to keep surface temperatures within the project’s T-rating under worst-case duty.

-

Mechanical integrity: duty-appropriate motors/gearing, smooth acceleration to reduce swing; optional anti-sway and inching modes.

Quick Comparison (at a glance)

| Model | Bridge Type | Hoist Type | Typical Capacity | Bay Fit | Best For |

|---|---|---|---|---|---|

| LB | Single-girder, top-running | Low-headroom hoist | 1–20 t | Low headroom, general bays | Everyday EX lifting |

| LXB | Single-girder, underslung | Low-headroom hoist | 0.5–10 t | Crowded bays, no top runway | Dense layouts |

| LHB | Double-girder, top-running | Wire-rope hoist | 10–50 t | Long spans, higher hook | Higher capacity with hoist |

| QB | Double-girder, top-running | Open-winch | 20–200+ t | Process duty | Heavy/continuous service |

| QBE | Double-girder, top-running | Dual trolleys | 2×10–2×80 t | Project-specific | Synchronized lifts/turning |

| Clean EX | Single/Double | Hoist-based | 0.5–50 t | Clean + hazardous | Battery/pharma/chemicals |

Figures are indicative for early budgeting. Final values follow engineering and classification.

How to Specify (send this with your RFQ)

-

Area classification: gas/dust, zone, group, temperature class (T-rating)

-

Load data: capacity, load spectrum, starts/hour, duty hours

-

Geometry: span, hook path, approaches, building clearances, runway data

-

Speeds & control: hoist/trolley/bridge speeds, creep/anti-sway, pendant vs EX-radio

-

Power & cabling: voltage/frequency, conductor bar vs festoon, EX glands/seals

-

Environment: ambient temp/humidity, indoor/outdoor, corrosion category

-

Documentation: drawings, datasheets, O&M manuals, FAT/SAT scope; third-party inspection if required

-

Site conditions: installation access, test loads, acceptance requirements

Safety, Commissioning & Maintenance

-

Installation: follow hazardous area cable routing, sealing, spacing; verify equipotential bonding across bridge/trolley/runway.

-

Commissioning: function & overload tests, limit devices verification, temperature checks under representative duty.

-

Maintenance: periodic inspection of brakes, ropes/chains, hooks, enclosures and glands; recordkeeping and timely replacement of wear parts.

-

Change control: any modification to controls or devices must be reviewed for hazardous area impact.

Ready to specify?

Share your environment (dust/heat/cold/corrosion), duty class, bay height, span, and tooling (grab/magnet). We’ll return a risk-reduced package + drawings + a service plan.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

FAQs

Yes—when the radio set, antenna and enclosures are suitable for the specified hazardous zone and installed per site rules. Many sites still mandate a pendant in stricter zones.

Open-winch offers higher duty, wider speed tuning, and easier service for heavy/continuous processes; hoist-based designs are compact and economical for moderate duty.

Select dust-protection enclosures and glands, ensure dust-tight cable management, verify surface temperature versus deposited dust layers, and maintain effective bonding/grounding.

Start with a safety/engineering review to define zone, group and T-rating. We can provide preliminary layouts and options, then finalize components once the classification is issued.

General arrangement drawings, electrical schematics, parts lists, operating & maintenance manuals, and factory/site test records as defined in the purchase order. Additional inspections can be arranged upon request.

Latest Blog

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua

Cranes as the Backbone of Modern Steel Plants

Cranes as the Backbone of Modern Steel Plants How the Right Steel Plant Crane Solutions Drive Efficiency, Safety,

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios When people ask me about spider

How To Choose The Right Spider Crane

How To Choose The Right Spider Crane (Mini Crawler Crane) for a Project – My Practical Experience When

Low Headroom Wire Rope Hoist for Tight Workshops | SLKJCrane

Cost Saving Low Headroom Wire Rope Hoist for Tight Workshops When I visit customers’ workshops and warehouses, I

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice