50 Ton Double Girder Overhead Crane: Cost vs. ROI in Automotive Manufacturing

The automotive industry’s race toward electrification and lightweighting has made 50 ton double girder overhead cranes the strategic backbone of modern assembly plants. When a leading German automaker implemented these industrial titans, they achieved €1.8M annual savings and reduced production stoppages by 63%. This technical deep dive reveals how precision-engineered double girder systems deliver ROI within 14-28 months – with data-backed proof from automotive production lines.

⚙️ Structural Superiority: Why Double Girder Dominates Auto Manufacturing

1.1 Load Distribution Mechanics

Unlike single girder alternatives, double girder overhead lifting systems utilize parallel steel beams to:

Eliminate torsional stress at 125% SWL (62.5-ton test loads)

Enable walkable service platforms for predictive maintenance access

Achieve ≤L/1000 deflection limits (EN 1993-6:2022 standard)

Technical Comparison Table:

| Capability | Single Girder | Double Girder | Auto Manufacturing Impact |

|---|---|---|---|

| Max Span | 25m | 40m+ | Full coverage of body shop lanes |

| Headroom Efficiency | 300-500mm less clearance | Zero lost vertical space | Multi-level production layouts |

| Lateral Stiffness | 1:800 span ratio | 1:1000 span ratio | ±1mm positioning for battery mating |

| Duty Rating | CMAA Class C (Moderate) | CMAA Class E (Continuous) | 24/7 EV battery production |

Real-World Validation: A Spanish EV plant handles 2,400kg battery packs with ±0.5mm repeatability during automated transfers – impossible with single-beam configurations.

💰 Total Ownership Cost Analysis

2.1 Capital Investment Breakdown

*Table: 50-Ton Double Girder System Components*

| Component | Specification | Cost Range | Automotive Criticality |

|---|---|---|---|

| Main Girders | S355JR steel w/ FEA optimization | $98K-$165K | Fatigue resistance (500k cycles) |

| Hoist System | AC frequency control + encoder feedback | $68K-$120K | Micro-speed (0.5m/min) precision |

| Runway Beams | Reinforced box section (ISO 12488-1) | $45K-$85K | Vibration damping for robotics |

| Smart Control Package | AI anti-sway + collision avoidance | $72K+ | Prevents $500K+ damage incidents |

Total Project Investment: $283K-$440K

📈 ROI Calculation: Automotive Production Case Study

Project: Transmission Manufacturing Plant (Central Europe)

Challenge: 32% downtime from material handling bottlenecks

| Metric | Before Installation | After 50-Ton Deployment | Improvement |

|---|---|---|---|

| Hourly Throughput | 22 transmissions | 31 transmissions | +41% |

| Damage Incidence | 3.7% | 0.6% | 84% reduction |

| Changeover Time | 47 minutes | 19 minutes | 60% faster |

| Energy Cost/Unit | €9.20 | €5.85 | 36% savings |

ROI Achievement: 16 months (including automation package)

5-Year Savings: €3.2M

🔧 Automotive-Specific Engineering Solutions

3.1 Precision Control Systems

Adaptive Anti-Sway AI: Machine learning algorithms compensate for load dynamics

Laser-Guided Positioning: ±0.5mm accuracy for powertrain assembly

EMC-Shielded Electronics: Immunity to welding robot interference

3.2 Environment-Specific Configurations

| Production Zone | Crane Enhancement | Technical Standard |

|---|---|---|

| Paint Shops | ATEX Zone 1 explosion-proofing | IECEx/ATEX certification |

| Battery Assembly | ISO Class 5 cleanroom package | UL 583:2023 compliance |

| Foundry Areas | 1,650°C thermal barrier systems | ASME B30.11 reinforcement |

🚀 Industry 4.0 Integration

4.1 Smart Monitoring Systems

Vibration Analytics: Detect bearing wear 800+ hours pre-failure

Wire Rope IoT Sensors: Real-time remaining life calculation (ISO 4309)

Digital Twin Integration: Synchronize with Siemens/MES platforms

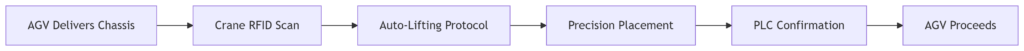

4.2 Autonomous Material Flow

Implementation Result: 29% faster line balancing at Czech Skoda plant

✅ Implementation Roadmap

Phase 1: Facility Assessment (4-6 Weeks)

Structural Audit: Laser scan runway alignment (≤±3mm tolerance)

Power Mapping: 480V/60Hz 3-phase with 150% motor starting capacity

Process Simulation: Discrete event modeling of material flow

Phase 2: Custom Engineering

Specialized Attachments:

Battery module vacuum lifters

Engine cradle spreader beams

BIW panel magnetic handlers

Phase 3: Validation & Training

Load Testing: 125% SWL static test + 500k dynamic cycles

Operator Certification: CMAA-compliant competency program

Digital Handover: Augmented reality maintenance manuals

If you need to know more questions, please consult our professional team for free:

✅ 24/7 emergency service

✅ On-site vibration testing

✅ Guaranteed dB reduction

All News

Recent Posts

2025/1/25

2025/2/7

2024/8/1

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice