15 Ton Gantry Crane Kits for Sale | Local Assembly & Bulk Orders – SLKJCrane

For many workshops, fabrication yards, and steel plants, a 15 ton gantry crane is a practical “middle range” solution. It can handle plates, molds, and machinery parts without requiring oversized foundations or special transport.

To support overseas projects, SLKJCrane supplies 15 ton gantry crane kits that are designed for local assembly. Instead of receiving a fully assembled crane, you receive modular components that can be installed by your own team or local contractor. This approach is especially attractive when you need multiple cranes for the same group or project.

If you need other gantry cranes, you can check out our overview

What Is a 15 Ton Gantry Crane Kit?

A 15 ton gantry crane kit is a package of all key crane components delivered in sections for on-site assembly. It is suitable for new plants, retrofit projects, and sites where transporting a complete crane is difficult or expensive.

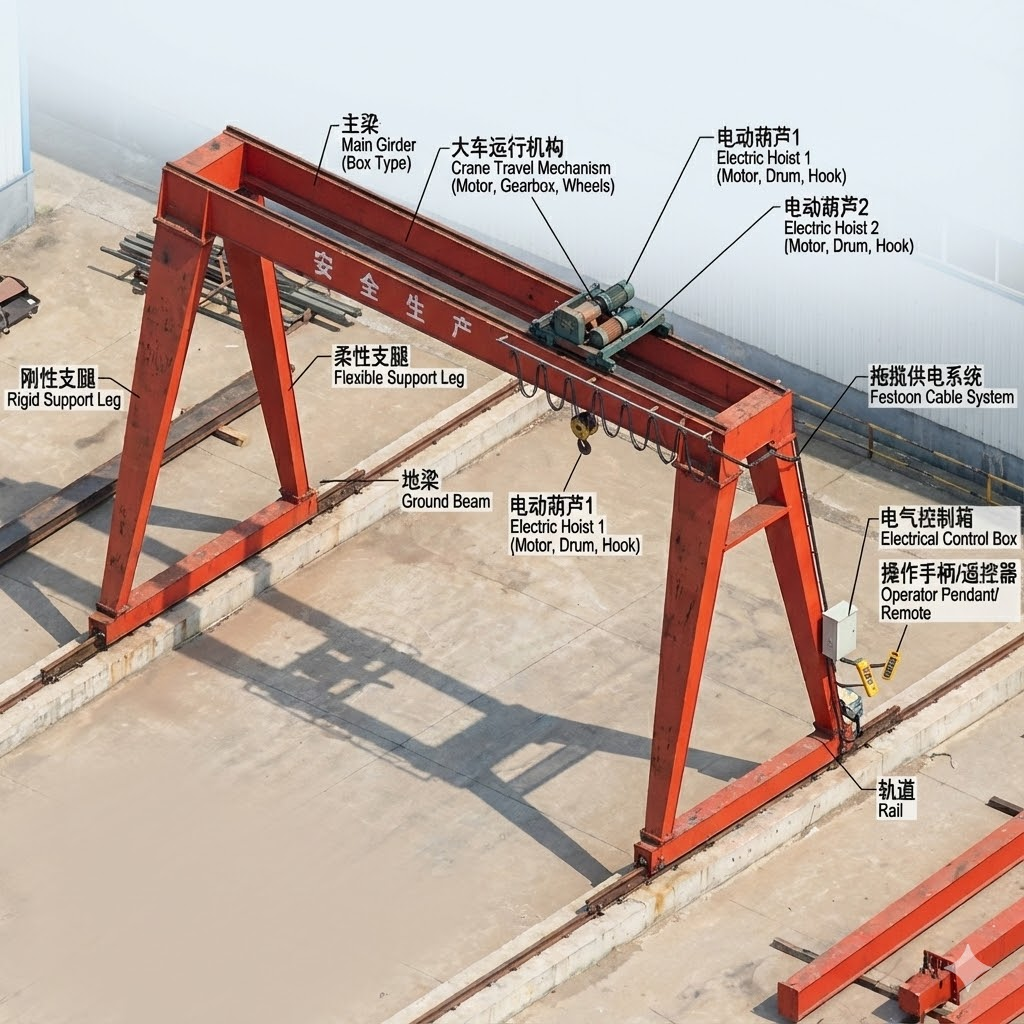

Typical components include:

Main girder(s) – define the span and carry the 15 t load

End carriages / end trucks – wheel sets and drive units for gantry travel

Legs and ground beams – for full gantry structures, with options for ladders and platforms

Electric hoist and trolley – standard or low-headroom 15 t hoist with cross travel trolley

Electrical system – control panel, motors, cables, power supply system, limit switches

Bolts and connection parts – high-strength fasteners and brackets for local assembly

Because the crane is delivered in modules, handling, unloading, and storage are simpler than with a pre-assembled structure.

Why 15 Ton Gantry Cranes Are Popular

A 15 t gantry crane is often chosen because it:

Covers most medium-to-heavy lifting tasks in general manufacturing, steel fabrication, and construction

Fits into existing buildings or yards without extreme civil work

Can be configured as single girder, double girder, semi-gantry, or outdoor gantry according to site layout

For many buyers, 10 t is too small and 20–32 t is more than necessary. 15 t becomes a sweet spot for both cost and capacity.

Advantages of Local Assembly

Choosing a 15 ton gantry crane kit for local assembly offers several practical advantages, especially for projects in the Middle East, Africa, Southeast Asia, and Latin America.

1. Lower Transport and Import Costs

Modular components are easier to load into containers and avoid many oversize transport issues

In some countries, duties and taxes on parts are lower than on complete machines

You can use local cranes and forklifts to unload and erect the structure

2. Better Fit to Your Site

Local assembly allows you to:

Match the span and height to actual clearances, obstructions, and production lines

Configure hoist position, travel limits, and working area around your workflow

Add local platforms, walkways, and protection according to your safety rules

The crane is adjusted to your process, not the other way around.

3. Shorter Overall Project Time

Foundations, rails, and power supply can be prepared while the kit is being manufactured and shipped

Once the kit arrives, your team can start installation immediately with our drawings and guidance

You do not have to wait for an overseas erection team to arrive and schedule around them

4. Use of Local Skills and Standards

Local engineers and contractors understand national standards, inspection requirements, and site procedures

Future maintenance, inspections, and small modifications are easier to manage locally

SLKJCrane provides clear manuals and diagrams, while you keep control of on-site execution

When Bulk Orders Make Sense

Ordering multiple 15 ton gantry crane kits at the same time is often more economical than buying single units.

Large Industrial Projects

Steel mills, fabrication yards, precast concrete plants, and shipyards

Multiple bays or lines using the same crane type for material handling

Workshops with Several Cranes

Standardized components simplify training and maintenance

The same spare parts fit more than one crane

Operators can move between cranes with minimal retraining

Cost & Management Benefits

Supplier can offer better prices per unit on bulk orders

Shared engineering, packaging, and logistics reduce total project cost

In case of downtime on one crane, other units can temporarily cover critical tasks

For EPC contractors or groups with several plants, bulk purchasing of 15 t gantry crane kits helps control both cost and technical risk.

Local Assembly – Simple Step-by-Step Overview

Every site is different, but most 15 ton gantry crane kit installations follow a similar sequence.

1. Preparation

Check ground level, foundations, and rail alignment

Confirm there is enough space for assembly and lifting operations

Prepare power supply, earth connection, and safe access routes

2. Mechanical Assembly

Assemble end carriages, legs, and main girder(s) on the ground

Install hoist and trolley and verify smooth movement on the girder

Lift the gantry structure onto rails using local cranes or lifting equipment

3. Electrical Installation

Mount control panel, motors, cable systems, and limit switches

Connect power and control wiring according to the supplied diagrams

Set parameters for soft start, braking, and protection devices if using VFD drives

4. Safety Checks and Testing

Perform no-load and test-load lifting trials

Check travel, braking, limit switches, and emergency stop functions

Record results for future inspection and certification if required

With proper planning and a skilled team, installation of a 15 t gantry crane kit can usually be completed in a short time frame, once foundations and rails are ready.

Buyer Checklist Before Requesting a Quote

To help us design the right 15 ton gantry crane kit and provide a clear price, please prepare the following information:

Capacity

Main hook 15 t (any need for an auxiliary hook?)

Span

Distance between rails or required clear span

Lifting height

From floor level to hook at highest working position

Crane travel length

Total distance the gantry needs to travel

Usage & duty

How many hours per day and how often it lifts near full load

Environment

Indoor or outdoor, temperature range, dust, humidity, or corrosive atmosphere

Power supply

Voltage / phase / frequency available on site

Control mode

Pendant, radio remote, or a combination

Providing this data at the beginning helps us quickly recommend a suitable 15 t gantry crane configuration and a realistic budget.

Conclusion: Is a 15 Ton Gantry Crane Kit Right for You?

If you need a crane that can:

Handle everyday medium-to-heavy lifting

Fit into existing facilities without major reconstruction

Be installed using local resources and standards

Scale easily when you need multiple units across different bays or plants

…then a 15 ton gantry crane kit for local assembly is a strong option.

By choosing SLKJCrane as your supplier, you receive:

A complete, export-ready gantry crane kit

Clear drawings and installation guidance

Flexible configurations for different industries and climates

Support for both single projects and bulk orders

Send us your basic project data (capacity, span, lifting height, travel length, power, and working conditions), and our engineers will propose a 15 ton gantry crane solution tailored to your site and budget.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

FREQUENTLY ASKED QUESTIONS

———15 Ton Gantry Crane Kits & Local Assembly

Q1. Is a 15 ton gantry crane suitable for outdoor use?

Yes. We can supply outdoor-type 15 t gantry cranes with weatherproof motors, outdoor coatings, rain covers, and appropriate IP protection. Just let us know your environment (sun, rain, wind, coastal, etc.).

Q2. Can I install the 15 t gantry crane kit with my own team?

In many cases, yes. As long as your team has basic experience in steel fabrication and lifting operations, you can assemble the kit following our drawings and manuals. We can also cooperate with your local installation partner.

Q3. Do you provide rails and power supply systems?

Yes. We can provide rails, clips, pads, power supply systems (cable festoon, busbar) and other accessories as part of the kit. You can choose “full package” or only main crane components.

Q4. How long does it take to assemble a 15 ton gantry crane kit?

For a standard 15 t single girder gantry crane, a skilled team can typically complete installation and commissioning within 3–5 days after foundations and rails are ready. Complex layouts or multiple cranes may take longer.

Q5. Can the span or lifting height be modified later?

Minor adjustments are possible during installation (for example, micro-adjusting span or rail gauge). However, any major change after fabrication will affect structural strength and must be checked by SLKJCrane engineers in advance.

Q6. Can I order multiple 15 ton gantry crane kits for different sites?

Yes. Many customers place bulk orders for several identical or similar cranes to standardize their equipment. This reduces spare parts inventory, simplifies operator training, and often provides better pricing per unit.

Q7. How do I start a project with SLKJCrane?

Simply send us your capacity, span, lifting height, travel length, power supply, and working conditions. Our team will prepare a technical proposal + price offer for your 15 ton gantry crane kit and suggest the most economical configuration for your site.

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice