10 Ton Overhead Crane Design Solution: Solving Workshop Pain Points for Safer, More Efficient, and Cost Effective Lifting

In modern industrial workshops, material handling is the backbone of production. Once lifting equipment becomes unreliable, the consequences range from slowed production and rising labor costs to serious safety risks and unexpected downtime.

As one of the most widely used capacities, the 10 ton overhead crane is a true all-rounder in mechanical manufacturing, steel structure fabrication, and equipment maintenance. However, many buyers overlook a critical fact: two cranes rated at 10 tons can perform very differently. Design differences can result in a 5-year lifespan gap, 30% variance in maintenance costs, and significant efficiency losses over time.

Choosing the right 10 ton bridge crane is not just about meeting load parameters. It is about whether the design truly addresses your real workshop challenges. Below, from an engineering and application perspective, we break down the core design strengths of our solution and explain how it delivers long-term operational value.

1. Why a 10 Ton Overhead Crane Is a Practical Workshop Standard

For most industrial users, a 10 ton overhead crane system strikes the ideal balance between performance and investment:

More stable and reliable than light-duty cranes, covering the majority of daily material handling needs

Over 50% lower initial investment than heavy-duty cranes, with reduced energy consumption and maintenance costs

Suitable for both new workshops and retrofit projects without major steel structure modification

The key difference lies here:

Standard cranes only ensure “lifting capability,” while a well-engineered crane ensures safe lifting, precise positioning, and long-term cost efficiency—the true drivers of workshop productivity.

If you are researching up-to-date cost insights before ordering, you may find our Overhead Crane Price in Egypt 2025 Buyer’s Guide useful for comparing suppliers, pricing trends, and real project examples.

2. Eight Core Design Advantages That Eliminate Common Industry Problems

1) Main Girder Design: High Strength, Low Vibration, 30% Lower Maintenance Cost

The main girder is the backbone of any 10 ton overhead crane. We adopt a box-type welded girder with optimized internal diaphragms, ensuring excellent bending and torsional resistance while controlling self-weight.

For users, this means:

Service life exceeding 15 years without rail deformation or girder cracking

Lower operating noise and improved workshop environment

Significantly reduced inspection and reinforcement frequency

2) Hoisting Mechanism: Precision Lifting with Maximum Safety

The hoisting system directly determines lifting safety. Our design follows safety factors exceeding national standards:

Wire rope, sheaves, and drum precisely matched to the 10-ton rated load for balanced stress distribution

High-precision gearbox ensures smooth, shock-free lifting, even for sensitive equipment

Integrated overload protection system that stops operation instantly if the rated capacity is exceeded

This is why it’s critical for every crane user to refer to a crane safety checklist, as discussed in our Crane Safety Guide: Ensuring Safe Operations and Accident Prevention when reviewing your workshop’s safety measures.

3) Traveling Mechanism: Ideal for Workshop Retrofits

For factories upgrading existing facilities, we optimize the crane traveling system by:

Accurately calculating wheel loads to avoid additional stress on existing runways and structures

Using high-strength, wear-resistant wheels with precisely matched drive and braking systems

Achieving ±5 mm positioning accuracy in both longitudinal and cross travel, improving handling efficiency by up to 20%

4) 3D Modeling: Zero Rework, Installation Time Reduced by 15 Days

The entire crane is designed using SolidWorks 3D modeling, allowing full simulation of assembly and maintenance access:

Eliminates on-site conflicts caused by space constraints or component interference

Provides clear installation drawings for one-time successful erection

Perfectly matches existing workshop layouts in renovation projects without additional civil work

5) Finite Element Analysis: Stability Under Extreme Conditions

Critical structures undergo ANSYS finite element analysis, covering self-weight, rated load, and dynamic forces:

Ensures structural stability under high temperature, heavy load, and continuous operation

Enhanced protection design for dusty, humid, or corrosive environments, reducing long-term wear

6) Comprehensive Safety Configuration Meeting International Standards

The crane complies with GB/T 3811-2008, ISO 4301, and related international standards, featuring:

Upper and lower limit switches, emergency stop buttons, and reliable braking systems

Fault alarm system for rapid troubleshooting

Fully enclosed electrical control cabinet with dust- and water-resistant protection

7) Easy Maintenance: Daily Inspection in Just 10 Minutes

Maintenance efficiency is built into the design:

Wire ropes, hooks, and wear parts accessible from ground level

High standardization of components for easy replacement and lower spare-part costs

Dedicated maintenance passages to minimize downtime during inspections

8) Energy Efficient Operation: Saving Thousands in Annual Power Costs

With high-efficiency motors and variable frequency drives (VFD):

Energy consumption is reduced by up to 40% during no-load operation

Stable output under full load without unnecessary power waste

Annual electricity savings of approximately USD 1,100–1,700 compared to conventional cranes

3. Who Should Upgrade to a 10 Ton Overhead Crane Now?

This optimized 10 ton overhead crane solution is ideal if your workshop faces:

Excessive lifting sway and inaccurate positioning

High maintenance costs and frequent breakdowns

Insufficient safety protection on older equipment

New workshop projects requiring a future-proof lifting system

4. Why Choose Our 10 Ton Overhead Crane Design?

We do not offer generic cranes—we provide application-specific lifting solutions:

Over 20 years of industrial crane design experience across 300+ projects

Every crane validated by 3D modeling and finite element analysis, with 100% load testing before delivery

One-stop service from design and manufacturing to installation and commissioning

24-hour after-sales response and spare parts delivery within 3 days

Take Action: Get Your Free 10 Ton Overhead Crane Design Proposal

Wondering whether this 10 ton overhead crane suits your workshop and operating conditions?

Contact us now and provide your workshop span, lifting height, and duty cycle. We will deliver:

Equipment suitability evaluation

3D layout simulation

Long-term operating cost analysis, including energy and maintenance

For a limited time, inquiries receive one year of free maintenance service. Let professional crane design improve efficiency, reduce costs, and enhance safety—start your inquiry today.

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

Eileen

With 20+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

FAQ: 10 Ton Overhead Crane Selection and Application

A: 10 ton overhead cranes are widely used in mechanical manufacturing, steel structure fabrication, equipment maintenance workshops, and medium-duty assembly lines.

A: With proper design and maintenance, a high-quality 10 ton bridge crane can operate reliably for 15–20 years.

A: Yes. With accurate wheel load calculation and optimized traveling mechanisms, it is well-suited for retrofit projects without major structural modification.

A: While not mandatory, VFD significantly improves positioning accuracy, reduces energy consumption, and extends component lifespan.

A: Key parameters include workshop span, lifting height, duty classification, power supply, and operating environment.

10 Ton Overhead Crane Design Solution for Industrial Workshops

10 Ton Overhead Crane Design Solution: Solving Workshop Pain Points for Safer, More Efficient, and Cost Effective Lifting

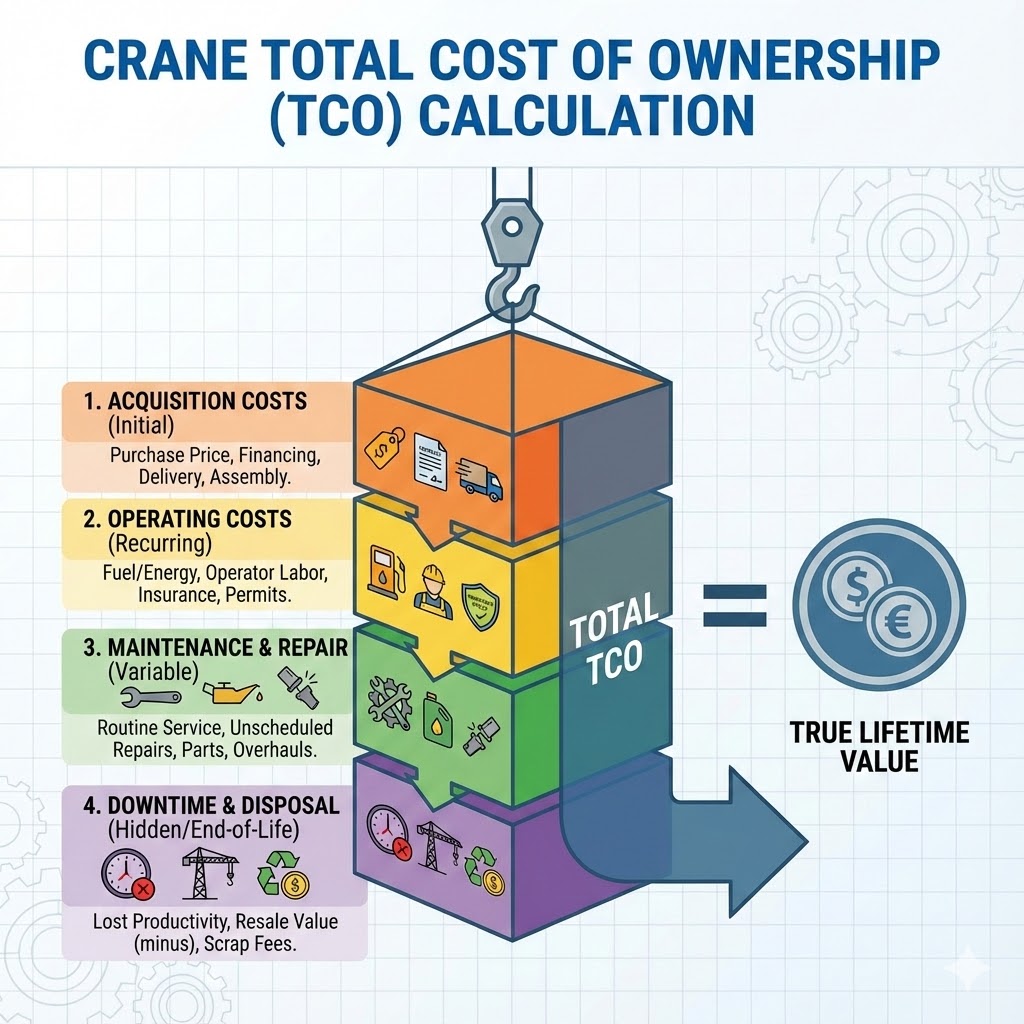

How to Calculate Crane Total Cost of Ownership (TCO)

How to Calculate Crane Total Cost of Ownership (TCO) A Practical Decision Guide for Industrial Projects in the

Cranes as the Backbone of Modern Steel Plants

Cranes as the Backbone of Modern Steel Plants How the Right Steel Plant Crane Solutions Drive Efficiency, Safety,

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios

Where Spider Cranes Really Shine: 7 Typical Applications & Real Project Scenarios When people ask me about spider

Contact Us Now

Have questions about our cranes or need help?

Reach out to our friendly team for expert support and guidance.

We are here to help you power your journey towards a greener future !

Address: Crane Industry Park, Xinxiang City Henan Provice